Published By VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Biogas Generation ISBN: 0-86619-204-2 [C]1984, Volunteers in Technical Assistance PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Leslie Gottschalk as primary editor, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

Richard Mattocks, author of this paper, is an environmental scientist with Draper-Aden Associates, Inc. He specializes in the management of solid waste materials and the recovery of biomass products, and is currently researching various uses of biogas digester effluent, particularly its use as an animal feed source. Reviewers J.B. Farrell, C. Gene Haugh, and Daniel Ingold are also specialists in the area. Farrell is a chemical engineer by training and chief of the Sludge Management Section of the U.S. Environmental Protection Agency's Municipal Environmental Research Laboratory. Haugh heads the Department of Agricultural Engineering at Virginia Polytechnic Institute. Ingold, a biophysicist, is a research engineer at Appropriate Technology Corporation.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

HISTORY

Biogas is a by-product of the biological breakdown--under oxygen-free conditions--of organic wastes such as plants, crop residues, wood and bark residues, and human and animal manure. Interest in biogas as a viable energy resource has spread throughout the globe in the past two decades. Biogas generators or digesters operate throughout Asia, for example, with more than 100,000 reported in India, about 30,000 in Korea, and several million in China. Many more are operating in the Middle East, Africa, Oceania, Europe, and the Americas.

Biogas is known by many names--swamp gas, marsh gas, "will o' the wisp," gobar gas. It contains about 50 to 60 percent methane, the primary constituent of natural gas. Biogas is produced naturally from the degradation of plants in such situations as rice paddies, ponds, or marshes. Because it can also be produced and collected under controlled conditions in an airtight container, it can be an important energy source.

Ancient Chinese experimented with burning the gas given off when vegetables and manures were left to rot in a closed vessel. More recently, Volto, Beachans, and Pasteur worked with biogas-producing organisms. At the turn of the 20th century, communities in England and Bombay, India, disposed of wastes in closed containers and collected the resulting gas for cooking and lighting. Germany, the United States, Australia, Algeria, France, and other nations constructed such methane digesters to supplement dwindling energy supplies during the two world wars.

NEEDS SERVED BY THE TECHNOLOGY

Biogas generators or digesters yield two products: the biogas itself, and a semi-solid by-product called effluent or sludge.

Biogas systems are most popular for their ability to produce fuel from products that might otherwise be wasted--crop residues, manures, etc. The fuel is a flammable gas suitable for cooking, lighting, and fueling combustion engines.

The digested waste--sludge--is a high quality fertilizer. The digestion process converts the nitrogen in the organic materials to ammonium, a form that becomes more stable when plowed into the soil. Ammonium is readily "fixed" (bonded) in soil so that it can be absorbed by plants. In contrast, raw manure has its nitrogen oxidized into nitrates and nitrites, which do not "fix" well in soil and are readily washed away.

Moreover, biogas systems offer a means to sanitize wastes. Simply put, these systems are capable of destroying most bacteria and parasitic eggs in human and animal wastes, enabling the digested sludge to be applied safely to crops. Tests have shown that biogas systems can kill as much as 90 to 100 percent of hookworm eggs, 35 to 90 percent of ascarid (i.e., roundworms and pinworms), and 90 to 100 percent of blood flukes (i.e., schistosome flukes, which are found in water snails that commonly live in paddy fields and ponds).

Biogas systems are also capable of digesting municipal sewage, which is a major source of pollution. Using biogas systems in this way substantially reduces the potential for environmental pollution.

Finally, agricultural and animal wastes, the major raw materials for biogas production, are usually plentiful in rural areas. People living in rural communities, who are often subjected to the price and supply fluctuations of conventional fuels and fertilizers, can benefit directly from biogas systems.

It should be noted that, while this paper focuses on the production of biogas for fuel, in some applications the gas is considered to be the by-product of the process. Some digesters in China, for example, are used primarily for treating sewage and producing fertilizer, and only secondarily for producing fuel.

II. OPERATING PRINCIPLES

BASIS OF THE TECHNOLOGY

Biogas generation is a process that takes place in an oxygen-free environment. It uses anaerobic bacteria--bacteria that live only in the absence of oxygen--to break down complex organic compounds in fairly well-defined stages. The process is called anaerobic digestion. It produces biogas, a gas composed of approximately 50 to 60 percent methane, 40 to 50 percent carbon dioxide, as well as water vapor and a small quantity of nitrogen, sulfur, and other trace compounds. Biogas is flammable, which is what makes it useful, but it has a relatively low heat content, approximately 6.1 Calories per liter (around 600 BTU per cubic foot). Compare this with pure methane, which has a heat value of 995 BTU per cubic foot, or natural gas with over 1,000. Nevertheless, biogas can be an important fuel source for many applications.

A biogas digester is the device in which the digestion process occurs. The organic feedstock, which is called the substrate, may consist of night soil, manure, crop or kitchen residues, or similar materials. The substrate is usually diluted with water, and is thoroughly mixed into a slurry; crop residues and vegetation are usually cut or chopped into small, fairly uniform pieces. It is then fed into the digester and permitted to undergo degradation in a sealed oxygen-free chamber. When digestion is completed, the material is discharged, or removed from the digester. The biogas is collected for direct usage or pressurized for subsequent use. The discharged material is called effluent, or sludge.

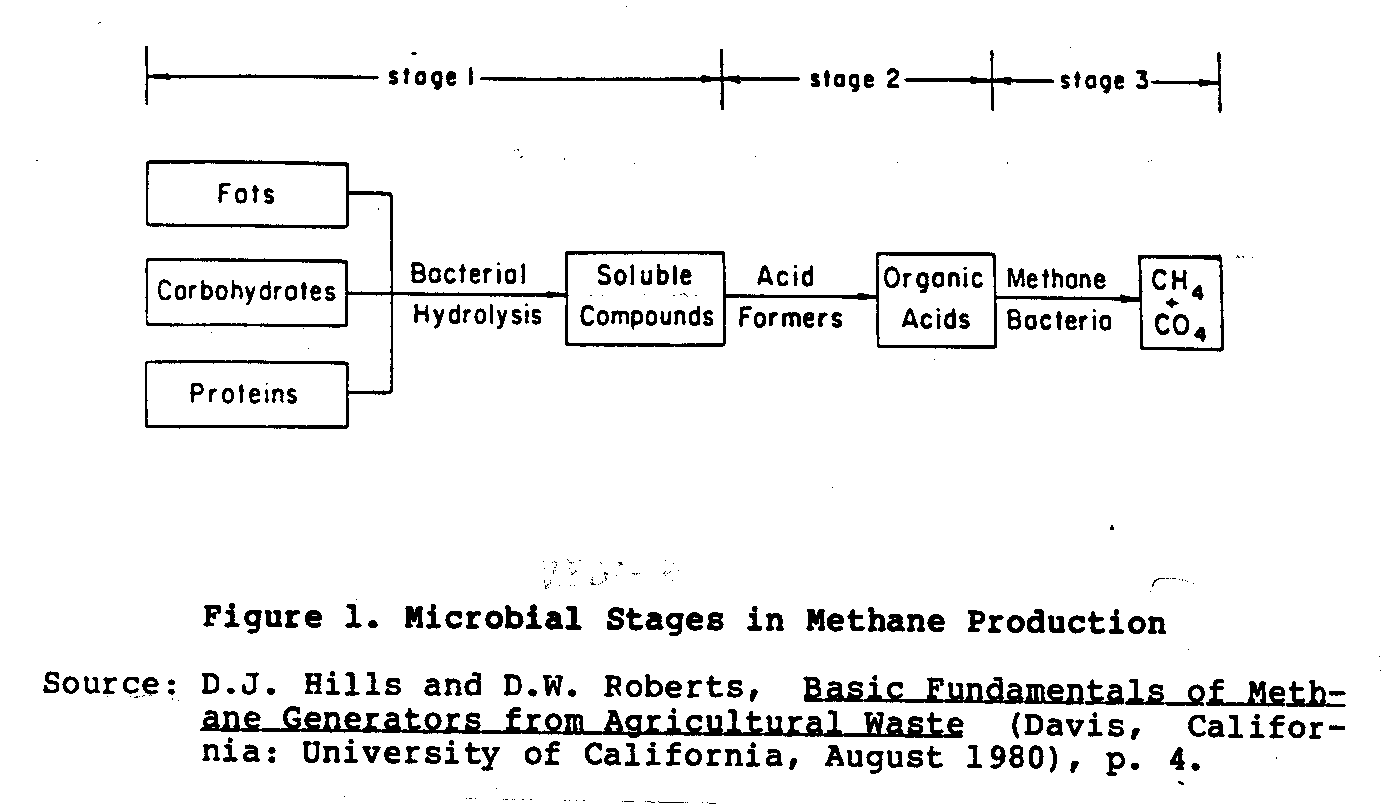

The actual breakdown of organic material inside the digester is a three-stage process that leads to the production of methane (Figure 1).

In the first stage, numerous organisms release enzymes that attack specific bonds in complex protein, carbohydrate, and lipid compounds in the incoming substrate. This stage of degradation converts the compounds into simpler molecules. Another set of organisms further degrades the molecules to form short-chain volatile fatty acids. At this point, various methane-producing organisms (or methanogens) use carbon dioxide or volatile fatty acids to produce biogas (a mixture of methane and carbon dioxide).

The principles of anaerobic digestion are the same regardless of the digestion vessel. Organic material is loaded into a fairly warm, temperature-controlled, oxygen-free environment and methane is produced after acclimatization. The makeup or quality of incoming material to be digested, the vessel, and the surrounding environment influence the digester efficiencies. The production of gases is greater when the digester is operated at a relatively high temperature, when the substrate is stirred or otherwise agitated, and when system conditions are kept fairly constant. A more detailed discussion of these and other factors influencing digester efficiency follows. In general, however, the important objective to keep in mind when operating a biogas digester is the production of the greatest volume of biogas in the shortest possible time.

FACTORS INFLUENCING PERFORMANCE AND SIZE OF BIOGAS DIGESTERS

Researchers are only now gaining a better understanding of the metabolic process in biogas digesters. They do know, however, that methane-producing organisms (called methanogens) "prefer" to channel energy, or calories (derived by breaking down incoming substrate), to methane rather than use the energy to construct or satisfy internal cellular needs. As such, methanogens do not adapt well to changes in their environment that may require them to increase their numbers or adjust their internal mechanisms. If the environmental changes are significant enough, the methanogens may slow or even stop their work.

Changes that may affect the behavior of the bacteria and thus the performance of the digester include variations in the substrate, presence of certain toxic chemicals, gas pressure, temperature, and the amount of time the material remains in the digester.

Other factors that could have a major impact on the operating performance of a biogas digester include biological balance/ acidity, solids concentration, agitation, feedstock, pretreatment, and the carbon-to-nitrogen ratio.

The primary factors that could affect the size of a biogas digester include the type and amount of feedstock, the rate at which it is loaded, and hydraulic retention time.

Factors Influencing Digester Operating Performance

Biological Balance/Acidity

Methanogens--methane-producing organisms--live in a syntrophic, or complementary, relationship with certain other microorganisms that consume the feedstock and produce simple acids as part of their metabolism. The simplest acids are essential to the metabolic processes of the methanogens. As acid-producing organisms tend to choke in their own acetic by-products, methanogens cooperate by consuming these by-products in the methane-producing process.

Given sufficient time to establish the proper ratio of methane-producing organisms to acid-producing organisms, a homeostasis, or stability, will occur with a pH of about seven in a digester. A digester fed poultry or high nitrogen waste may stabilize at a pH of eight or greater.

The objective here is to create a stable working relationship among the microbial population in the digester. This implies the need for fairly constant operating temperatures and feedstock characteristics. Conversely, any rapid variations of these conditions will cause the microbial population to shift dramatically and possibly upset the overall system balance in the digester. For example, if the methane-producing organisms become dormant due to, say, temperature fluctuations, the pH will drop so low as to incapacitate them.

Maintaining a stable pH requires stabilizing the feedstock as well as the operating temperature in the digester. If this proves impractical, adding lime or other buffering compounds to the digester will prevent the pH from falling. Note that the correct amount and type of buffering compound can be determined only on a case-by-case basis.

Four additional factors that could affect the overall system balance in the digester are:

- The concentration of the incoming solid waste could vary and either increase or decrease the amount of food to be consumed by the digester.

- Removing the slurry (the mixture of water and substrate added to the digester) from the digester or replacing it altogether, each day, will change the average age of the organisms in the digester.

- The average characteristics of the material being consumed by the microbial population in the digester will change in response to any fluctuations in the amount of feedstock material removed each day.

- The temperature, as well as the contents of the water used to dilute the incoming waste, will alter the nature of the food to be consumed by the digester.

Operating Temperature

Operating temperature is another factor influencing digester efficiency. A digester can operate in three temperature ranges: (1) the low temperature, psycrophilic bacteria range, which is less than 35[degrees]C (90[degrees]F); (2) the medium temperature, mesophilic bacteria range, which is 29 to 40[degrees]C (85 to 105[degrees]F); and (3) the high temperature, thermophilic bacteria range, which is 50 to 55[degrees]C (135 to 140[degrees]F). Organic material degrades more rapidly at higher temperatures because the full range of bacteria are at work. Thus, a digester operating at a higher temperature can be expected to produce greater quantities of biogas. The disadvantage of an elevated-temperature digester is that even minor changes in system conditions could offset digester efficiency or productivity. Moreover, an additional source of energy will likely be required to maintain the digester contents at a constant higher temperature.

Though operating temperature is critical, stabilizing the temperature and keeping it stabilized are even more important. Variations of plus or minus 1[degree]C in a day may force the methane-producing organisms into periods of dormancy. These organisms consume acids, and without them acids will accumulate and the pH will fall, impeding the effectiveness of the whole biogas system.

In northern latitudes or colder climates, the volume of methane will be substantially less unless specific provisions are made to preheat the incoming substrate and maintain the digester temperature. Thus, in colder climates, larger digesters will likely be required. Moreover, the amount of digester surface constructed above ground should be reduced when temperatures are low.

One way to overcome the problem of lower temperatures is to dilute the daily incoming waste material with preheated (solar-heated) water. Or you can construct a greenhouse or compost pile around the digester.

Note that the amount and type of waste to be degraded as well as the operating temperature are two important factors governing digester size.

Solids Concentration

The moisture content of the digestion liquor (waste that is diluted) should be in the range of 5 to 12 percent total solids. The percentage of total solids should include a minimum of inorganic sands and soils. Incoming waste products may have to be diluted to a consistency of slightly thick cream. A rule of thumb for diluting cattle waste is 2.5 parts water for every one part of relatively dry waste or one part water for every one part of fresh manure.

Stirring the Digester Contents

The microorganisms degrading the waste material are living, metabolizing creatures that produce their own metabolic by-products. To prevent the bacteria from stagnating in their own waste products, and thus to promote a more rapid digestion, stir or agitate the digester contents by paddle, Scraper, piston, or in more sophisticated settings, by gas recirculation.

Agitation also helps to minimize the build-up of internal fibrous scum on top of the digestion liquor. Failure to break the scum may result in excessive gas pressures forcing substrate out of the openings instead of permitting the gas to escape through gas transport lines. The scum may also plug the digester. Digesters that are fed higher volumes of fibrous waste may require special design considerations.

Feedstock Pretreatment

Feedstocks sometimes require pretreatment to increase the methane yield in the anaerobic digestion process. Pretreating the feedstock (with alkaline or acid treatments, for example) breaks down the complex organic structures into simpler molecules that are then more susceptible to microbial degradation.

Thus, you may want to pretreat any incoming substrate whose volatile solids are not readily degradable. Note that microorganisms do not readily act upon rice hulls or sawdust.

Fibrous wastes also require special handling. Wastes with long fibers such as straw should be chopped or broken. Any given waste will digest more rapidly, and possibly even more completely, when broken into bits. Thus, the finer the waste is shredded, ground, or pulped, the easier the digestion process will be.

Scientific research has determined that minimum levels of nickel, cobalt, and iron are required for methanogens to degrade organic wastes more efficiently. This is of little immediate consequence to most farmers, as chemical analysis is required to determine whether addition of these elements would be helpful.

Carbon-to-Nitrogen Ratio

If the carbon-to-nitrogen ratio is either too high or too low, or fluctuates substantially, the digestion process will slow or even stop. To act efficiently on the substrate, microorganisms need a 20-30:1 ratio of carbon to nitrogen, with the largest percentage of the carbon being readily degradable. Digesters have efficiently operated on poultry waste with a 5-7:1 ratio. The key here is to keep the quantity as well as the characteristics of the incoming substrate constant.

One note of caution: some carbon compounds resist being broken down. Lignin, for example, which all land plants use to help stiffen and support themselves, is the least readily degradable carbon compound. The amount of lignin increases proportionally with plant age. Thus, old grass contains more lignin than new grass, and wood contains more of it than do leaves. Remember, any substrate that contains a high percentage of lignin will not readily decompose in the biogas digester as well or as completely as substrates that contain lesser amounts. Thus, horse dung and mature vegetative waste material are probably not good feedstocks, because they contain a high fraction of non-degradable lignin.

Presence of Certain Toxins

Certain medications (e.g., antibiotics used in animal feeds or injected into animals), feed additives, pesticides, and herbicides may have adverse effects on anaerobic bacteria, particularly the methanogens. For example, lincomycin (frequently used in treating swine) and monensin (often used in treating cattle) are two antibiotics that will harm these bacteria and immediately halt methane production.

Factors Influencing Digester Size

Digester design depends basically upon the availability and type of waste to be fed to the digester, as well as the amount of gas and/or fertilizer required. Large digesters are generally designed after establishing system operating conditions through laboratory analysis. Small digestion plants are generally designed based on past experiences with a particular substrate.

A distinct advantage of small digesters over large ones is that their contents require less vigorous and less frequent stirring (only several times a day) to prevent scum buildup and thus increase the production of biogas. A principal disadvantage of these digesters, on the other hand, is that their operating temperatures tend to fluctuate more often and to a much greater degree.

Nevertheless, feeding a biogas digester--regardless of its size--any number of individual or combined feedstocks or organic materials will result in the production of biogas as long as the proper conditions exist and are kept fairly stable. These conditions were researched initially for sewage treatment plants and more recently are the subject of intense investigation toward meeting the waste management needs of various agricultural and specialized industries.

Type and Availability of Raw Waste Material

Husbandry practices can influence the quantities of manure available for use in the digester. For example, cattle in pasture will scatter their waste over a large grazing area, making waste collection difficult. Conversely, a herd that spends most of the day in a confined area (e.g., a corral) will deposit waste in a concentrated area, making it possible to collect waste more easily. Moreover, manure deposited directly in the field will likely contain a lot of soil or grit, which will eventually clog the digester, and thus not be suitable for the production of biogas.

The amount of manure produced per animal per day varies. For example, one may expect about six pounds per day from a 1,000 pound beef or dairy cattle and about nine or 10 pounds per day from 1,000 pounds of broiler chicken. Remember, increased gas production is directly proportional to the amount of volatile solids in the raw waste used.

Under optimum collection conditions (i.e., when animal is confined), you get:

4 lb of manure per 100-lb sheep 80 lb of manure per 1,000-lb dairy cattle 60 lb of manure per 1,000-lb beef cattle 10 lb of manure per 200-lb pig 45 lb of manure per 1,000-lb horse 0.2 lb of manure per 4-lb poultry layer

The rule of thumb here is that the waste material from two adult cattle will usually supply the gas required for cooking food for a family of four. Comparable quantities of other waste may produce slightly more or slightly less gas.

If you are considering relying on the use of a significant amount of vegetable waste in your digester, you need to know when such material will be available in the greatest quantities. For example, water hyacinth may be available year round in some climates, while grain straw or other crop residues will be most plentiful only at harvest.

Wilted or semi-dried vegetation may require the addition of water in order to maintain optimum solids concentration. Freshly-cut young vegetation may require less dilution than freshly cut older plant material.

Organic Loading Rate

The organic loading rate refers to the number obtained when the weight of the volatile solids loaded each day into the digester is divided by the volume of the digester. ("Volatile solids" refers to the portion of organic material solids that can be digested. The remainder of the solids are fixed. The fixed solids and a portion of the volatile solids are non-degradable. Organic material may also contain a substantial amount of water.)

Loading rate is an important parameter, since it tells us the amount of volatile solids to be fed into the digester each day. At high loading rates, the feeding has to be more nearly continuous (perhaps hourly). At lower loading rates, the biogas digester needs to be fed only once a day.

Digesters are designed to receive and treat from 0.1 to 0.4 pounds of volatile solids per cubic foot of digester volume. Although the actual loading rate depends on the type of wastes fed to the digester, 0.2 pounds of volatile solids per cubic foot of digester volume (approximately 3 kg per cubic meter) is a frequently used design parameter. This means a digester used to process mainly manure should be designed to accommodate from 20 to 120 cubic feet of digester volume per 1,000 pounds of live animal. (The actual amount varies from species to species.) Here, it is important to remember that a digester must be designed on the basis of the amount of waste that can be collected and actually fed to the digester, not on the quantity of waste produced.

For illustration, the following estimates are useful:

1 lb of volatile solids per 200-lb pig per day 1 lb of volatile solids per 1-lb sheep per day 0.04 lb of volatile solids per 4-lb poultry layer per day 6 lb of volatile solids per 1,000-lb beef or dairy cattle per day 9 to 10 lb volatile solids per 1,000 pounds of poultry layer

The percentage of water in animal waste on a unit volume basis is around 75 to 95 percent. Of the solids in the waste, about 70 percent are volatile. Percentage of water in vegetable and plant wastes varies from 40 to 95 percent. Of that, the percentage of volatile solids varies from 50 to 95 percent. The amount of biogas produced from vegetable and plant waste varies because various crops have differing biomass production rates.

With time, constant temperature, and a uniform incoming substrate, a digester will stabilize. The rules of thumb for any digester include:

- Incoming substrate 5 to 12 percent total solids;

- 0.2 to 0.5 pounds volatile acids per cubic foot of digester volume;

- 1 to 2 pounds raw manure per cubic foot of digester space per day; and

- 0.2 to 1.0 unit volume of biogas produced per unit volume of digester.

The actual amount of biogas that will be produced can be determined by experimentation under conditions similar to those at the site. One should experiment with various types of waste, the amount of water used to dilute an incoming waste, operating temperature, and feeding (loading) frequency.

A source of potential confusion in determining digester size is the means to measure gas production. When reading literature on biogas digesters, make sure that the gas production under discussion is in comparable units. Gas produced in a digester is biogas, of which 50 to 60 percent is methane; the remainder is carbon dioxide and other gases. Biogas volumes are distinct from methane volumes. Other ways of quantifying gas include: gas volumes per volume of digester, gas volumes per 1,000 pounds of live weight of an animal species, gas volumes per pound of volatile solids added, and gas volumes per pound of volatile solids destroyed.

Hydraulic Retention Time

Hydraulic retention time (HRT) is the average number of days a unit volume of substrate is to remain in the digester. Put another way, HRT is the volume of material already in the digester divided by the average amount of incoming daily feedstock, or the average age of the digester contents. The HRT will vary from 10 to 60 days, and is an important parameter because it influences the efficiency of the biogas digester.

Closely controlled digesters will average about 20 to 25 days retention time. Shorter retention times will create the risk of washout, a condition where active biogas bacteria are washed out of the digester at too young an age, making the population of bacteria unstable and potentially inactive. Daily conversion of organic material to methane will continue to increase per unit increase of weight (i.e., age) of bacteria up to a certain point. Thereafter, methane production will drop off per unit weight (or age) of bacteria.

Note that a longer retention time requires a larger digester and more capital for its construction. Recall, however, that the smaller the digestion vessel, the less time the methane-producing bacteria will have to act on the available substrate and thus the more likely the biogas system could malfunction. One should consider all these factors carefully before choosing a system.

III. DESIGN VARIATIONS

There are two general design characteristics of digesters: batch feed and continuous feed. The batch digester is loaded, sealed, and after a period of gas collection, emptied. A batch digester can essentially be any suitably sized container or tank that can be sealed and fitted with a means to collect the biogas. The continuous feed digester receives substrate on a continuous or daily basis with a roughly equivalent amount of effluent removed. There are many possible design variations for continuous feed digesters.

CONTINUOUS FEED DIGESTERS

The design variations for continuous feed digesters can be divided into four distinct types: the Indian design, the Chinese design, the sewage treatment plant, and the hybrid design. Each of these types, along with cost and construction considerations, is described in the sections that follow.

Indian Design

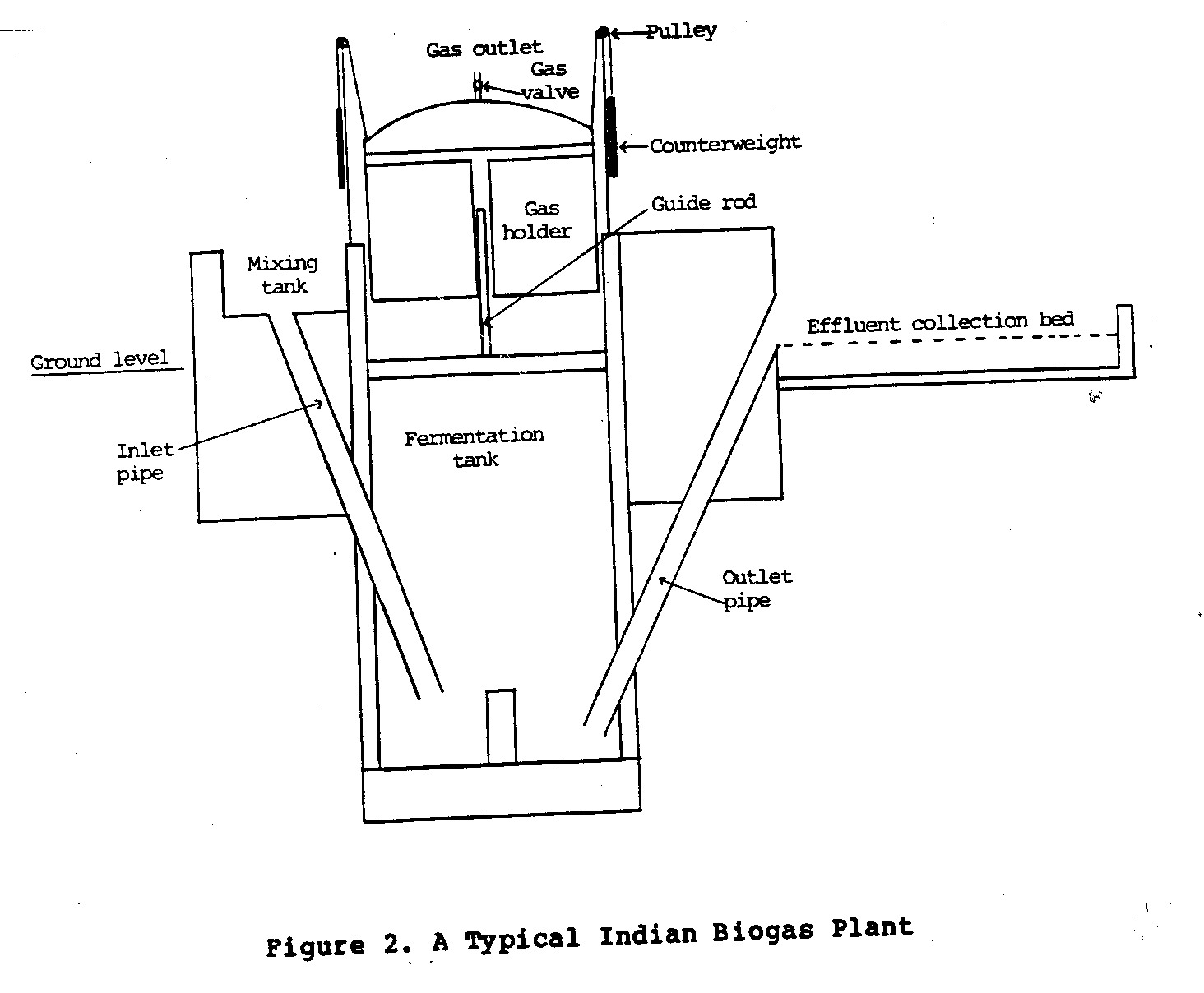

The Indian, or Khadi, design (Figure 2) is based on the principle

that gas produced will lift a bell-shaped dome located above the digestion vat. Substrate enters one side of the digester and displaces effluent out the other side. As gas is produced, it is collected under the dome, forcing it to rise. The dome descends as gas is forced out of the digester into the gas transport lines.

Chinese Design

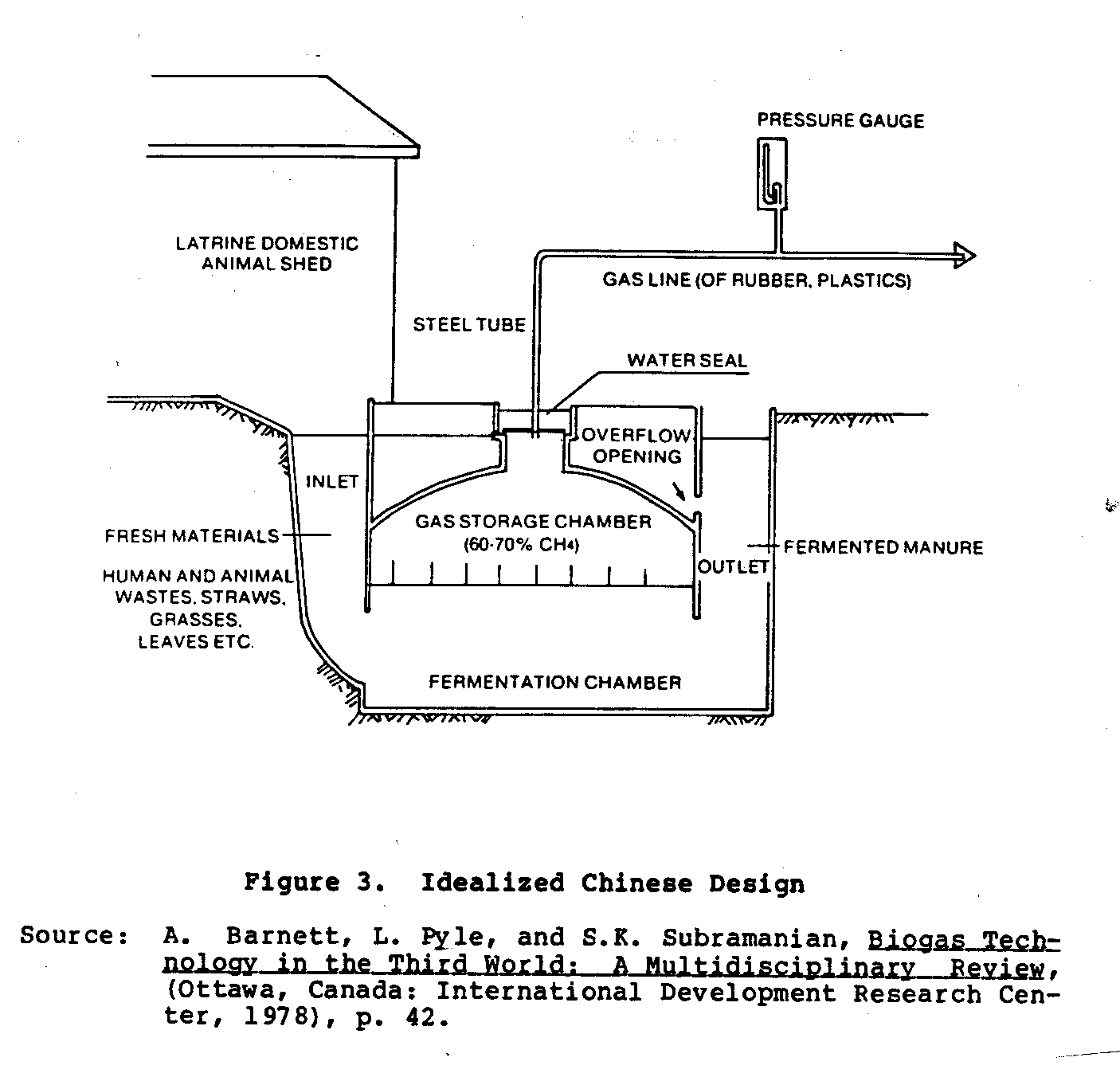

The gas storage chamber in the Chinese design characteristically has a fixed top (Figure 3). Substrate enters one side; effluent

exits the other side. Gas produced accumulates under the dome and above the vessel contents. Increases in gas volume displace digester contents into the displacement, or overflow, chamber. The materials forced into the displacement chamber will, by virtue of gravity, attempt to flow back into the digester. The attempt by the displaced liquor to flow back into the digestion vessel creates the pressure to force the gas into the gas transport line. As the gas is used, materials displaced into the displacement chamber will flow back into the vessel.

Sewage Treatment Plant

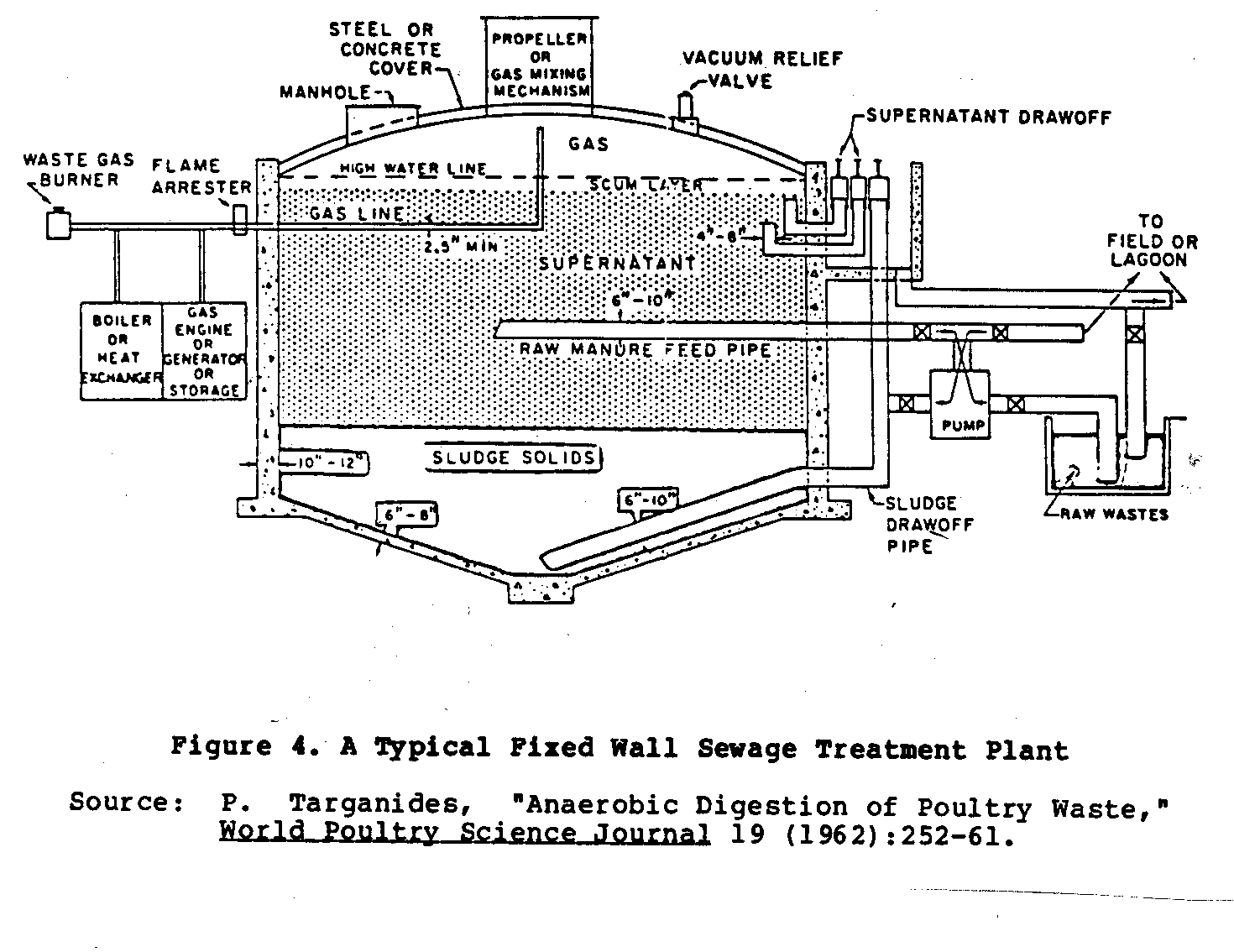

Though the designs associated with treating sewage or industrial wastes follow the same basic principles of the Indian and Chinese designs, they are much more complex and more efficient. The digester content is stirred either by paddle or gas recirculation. Temperature controls are much more stringent and digester content may be heated. The effluent exits the plant and is thickened prior to final disposal. Gas is tapped from the digester, possibly pressurized, and used for heating purposes or flared; it may be used for process heat in the digester. The sewage treatment plant principles may be employed on a much smaller scale with lower levels of technology. Figure 4 shows a high-technology sewage treatment plant.

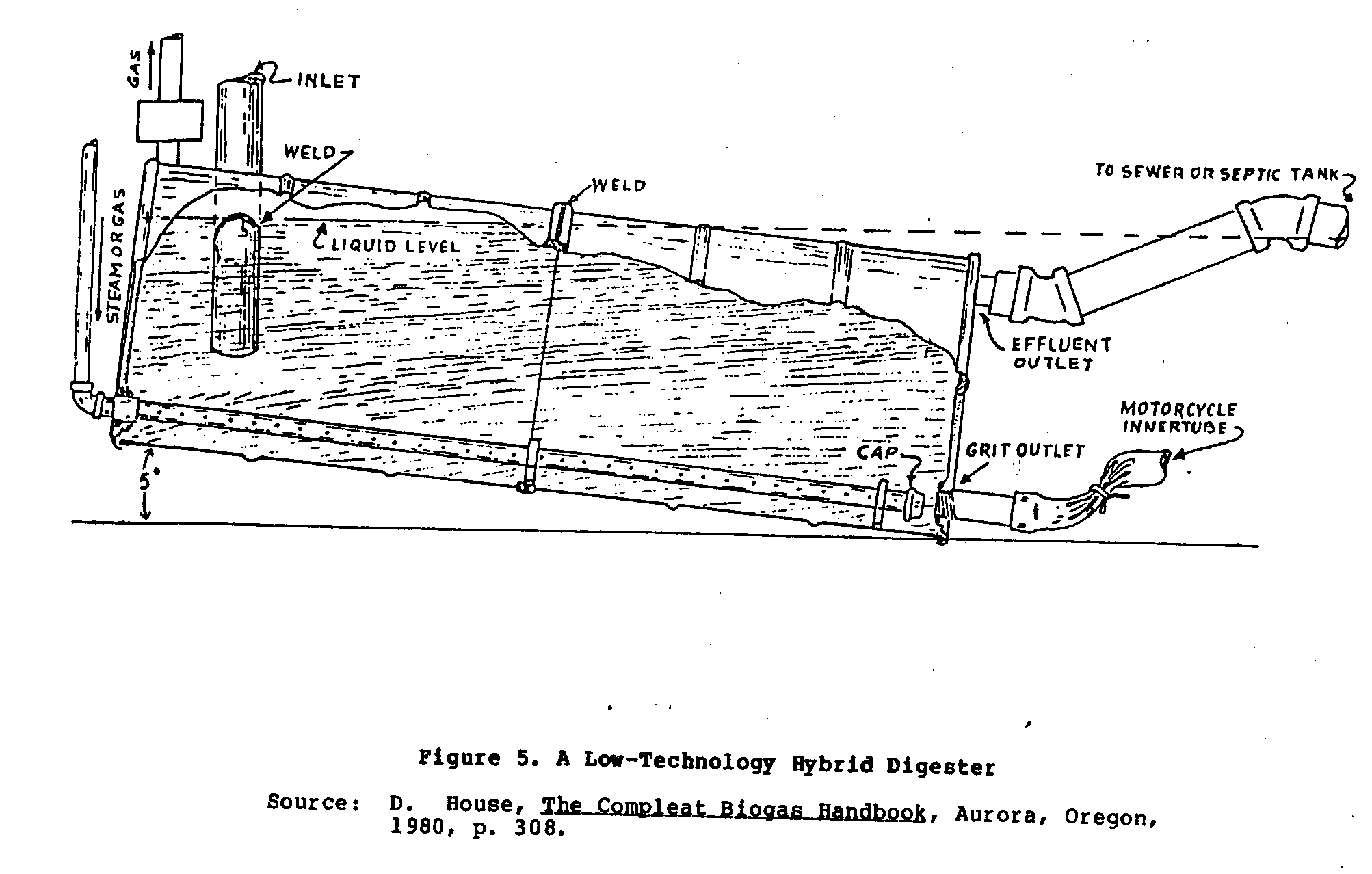

Hybrid Designs

Hybrid digesters imitate the principles employed in other designs, except that digestion vessels conform to the least expensive, most readily available construction materials. They can be built from available scrap materials, plastic bags, or covered troughs. A very simple design is the end-to-end welding of 55- gallon oil drums to create a long, narrow, small-volume continuous feed digester. With hybrid digesters, care must be taken not to let construction economy offset digester efficiency or productivity. Figure 5 shows a low-technology hybrid digester.

Comparison of Continuous Feed Digesters

The more sophisticated biogas digesters require skilled people to build, operate, and maintain them. Such digesters will likely be more economically feasible if they are used to process large quantities of waste. Although a high-technology digester does produce considerably more gas than either the Indian or the Chinese design, it has higher capital and operating costs and requires careful monitoring on a daily basis.

The Indian and Chinese designs are less expensive and easier to build and operate, but those benefits are countered by fairly inefficient gas production. Moreover, leakage may become a problem if the digesters are not maintained well. Although the Indian design produces slightly more gas than the Chinese design, it is slightly more expensive and has the added maintenance requirements associated with the floating dome.

APPLICATIONS

Biogas can be burned directly as a fuel for cooking, lighting, heating, water pumping, or grain milling, and can also be used to fuel combustion engines. In larger applications where scale and skills warrant, biogas can be pressurized and stored, cleansed for sale to commercial gas suppliers, or converted to electricity and sold to power grids, to meet peak energy needs.

Gas transport lines are connected to the gas-collection chamber of the digester (the floating dome of the Indian style digester). The gas has a high moisture content. It is necessary to devise a way to remove the moisture before the gas is used. One way is to slope the transport line back toward the digester so that the moisture will flow down the line back into the tank. If this is not practical, it will be necessary to install a sump, or chamber, in the gas line to collect the moisture.

Biogas is also very corrosive. It may contain dangerous amounts of hydrogen sulfide, a poisonous flammable gas that produces a highly corrosive acid when mixed with water. For this reason, gas transport lines must be corrosion resistant. Polyvinyl chloride (PVC) plastic pipe is a good choice for gas lines because it is durable, corrosion resistant, and usually economical. Because the gas is so corrosive, it may have to be cleansed before it is used, particularly in engines.

While biogas is an excellent fuel, it does have a fairly low energy value for its volume--500-600 BTUs per cubic foot--and the pressure in the distribution lines may be low. Lamps, stoves, refrigerators, and other appliances require specially designed jets to offset the low energy value and the low gas pressure. To stabilize the flame on a cookstove, for example, the jet forcefully shoots the biogas up through and out of the burner. Jets can either be purchased or built easily from locally available materials.

The amount of methane required daily per household will vary. About 0.5 to 1.0 cubic meter of biogas is required per family member for food preparation alone, and roughly one cubic meter of biogas is produced per 1,000 pounds of animal. Meeting one family member's cooking requirements, then, requires two or three healthy dairy or beef cows, or eight to 10 pigs (weighing 150 to 250 pounds each), or over 500 chickens. The amount of waste material produced by these animals varies with their health and diet and will influence the number of animals required. Collecting more than 30 to 40 pounds of waste daily per 1,000 pounds of live weight per animal will increase the amount of gas produced per animal.

The effluent leaving the digester at the end of the digestion period is spread on farmland much as the undigested manure, etc., is used. Research has been performed on using the digester effluent to feed cattle or to promote algal growth in fish ponds, as is done in some Chinese aquaculture installations.

CONSTRUCTION MATERIALS

The equipment and materials required for digester construction depend upon the level of technology employed. The basic Chinese design requires cement, sand, clay, lime, and bricks. Sulfate-resistant cement should be used if available due to the corrosive nature of the gas and slurry. The Indian design requires these same materials, plus some welding and iron works. The higher technology designs may require some specific machinery and electronics.

The following are generalized examples of the types and quantities of materials required to build similar sized Chinese- or Indian-style digesters.

A Brace Research Institute publication (1976) reports the following materials for an Indian-style, 3-cubic meter digester that should produce sufficient gas for the cooking needs of a family of six to eight members:

* 9 meters galvanized iron sheet * 3,200 small construction bricks * 25 50-kg bags of cement * 12 cubic meters of sand * various angle irons, iron pipes, etc.

The Khadhi and Village Industries Commission in Bombay, India, lists (in part) the following materials for a 3-cubic meter horizontal digester:

* 2,870 bricks * 3.2 cubic meters of sand * 1.9 cubic meters of 1/2" to 3/4" rock * 24 bags of cement * 7.5 meters of sheet steel * various angle irons, pipes, reinforcing rods.

A masonry wall Chinese style digester of 8 cubic meters calls for:

* 400 kg of cement * 1,000 kg of sand * 1,000 bricks * various plastic tubes for gas delivery.

Small-scale, nonpermanent digesters can be constructed of oil drums or uniformly-supported plastic bags.

The above materials are meant only for demonstration purposes. Actual type and quantity of materials required depend on design. Note, however, that smaller biogas digesters are generally built with readily available materials.

SKILLS REQUIRED TO PRODUCE AND OPERATE A BIOGAS DIGESTER

The basics of a digester can be creatively adapted by competent, local craftspeople working with locally available materials.

The Chinese design requires the skills of a competent mason. The Indian design requires the skills of a competent mason as well as an iron worker and welder.

More sophisticated digesters for larger scale applications require plumbers and electricians. Careful planning is required prior to building such facilities.

Once constructed, the digester requires the daily attention of a semiskilled individual. Each day, the digester must be fed and agitated, and the effluent properly disposed of. Just as a caretaker tends to a herd of animals, the individual responsible for the digester must understand the operational procedures. This person must maintain not only the digester's physical plant, but also ensure that the gas transport line and gas utilization system are operative and in good repair.

COSTS

Costs for construction are governed by the level of technology employed. They range from a few dollars for digesters built of readily available scrap to a few hundred dollars for a small family, Chinese-style digester, and from several hundreds of dollars for a small-scale Indian-style digester to several hundreds of thousands of dollars for a large-scale operation. A rule of thumb for comparable sized digesters is that the Chinese-style digester costs half that of a "drum"-style Indian digester. A more sophisticated digester will cost at least three times that of an Indian-style digester of comparable volume.

Actual costs depend upon the availability of resources. Large numbers of semi-skilled laborers, for example, suggest that construction of a Chinese-style digester would be more economical. On the other hand, even though an Indian-style digester costs more initially to construct, it is nevertheless more efficient, requires less maintenance, and produces more gas than a Chinese-style digester. Larger, more sophisticated digesters require markedly higher initial capital costs than smaller, less complex units. However, they are more efficient in terms of the total volume of organic material that can be handled per unit volume of digester, and they produce more gas per unit of organic material handled. To do a thorough cost analysis one must take into account such factors as inflation, interest rates, operating costs, maintenance expenses, labor costs, and the value of replacing conventional fuels (e.g., oil, gas) with biogas.

EFFICIENCY

The amount of biogas varies from 30 to nearly 100 cubic feet per 1,000 pounds of live body weight. Thus, there is no universal formula to determine biogas efficiency. To do so, one must consider many factors.

For example, biogas efficiency varies, depending upon how the biogas is used. Biogas plants use organic wastes, which, if not fed to a digester, are at best spread over land or at worst directly burned. Although direct combustion of dung or grasses yields at best 10 percent of the available energy, the nutrient values of such wastes are severely reduced. Biogas systems yield 40 to 50 percent, or better, of the thermal potential of organic wastes and yield a fertilizer of superior quality. Composting provides excellent fertilizer with no gas. Other, much more sophisticated procedures are also available for more efficient removal of energy from waste.

Moreover, efficiency varies with the type of digester, the operating conditions, and the type of material loaded into the digester. All else equal, the Chinese-style digester produces about half as much gas as the Indian-style digester, which in turn yields less than half the gas of more sophisticated units. The Chinese design, the Indian design, and the high-technology designs, respectively, yield about 0.2 to 0.3, 0.5 to 0.7, and 1.0 to 2.0 volumes of biogas per volume of digester. And, in general, digesters produce more gas with poultry waste (about 100 or so cubic feet of biogas per 1,000 pounds of live poultry weight) than they do with cattle waste (25 to 30 cubic feet per 1,000 pounds of live cattle weight).

Apart from these factors, the key to maintaining efficiency is to feed the digester a uniform feedstock daily, to maintain a constant operating temperature, and to agitate the contents regularly.

MAINTENANCE REQUIREMENTS

Biogas digesters require careful maintenance. Operators should be responsible for the following maintenance activities:

* Daily Activities: Collect and prepare the feedstock, and load it into the digester. Collect the liquid effluent from the digester. It may be spread over fields, used to fertilize fish ponds, or dried for later use.

* Periodic (at regular intervals) Activities: Remove the digester contents, including any solids that have accumulated at the bottom of the digester. Because of the potentially corrosive nature of the digester contents (slurry as well as gas), check all metal components of the digester to see whether they need to be resurfaced (e.g., the metal dome of the Indian-style digester).

* Occasional (at irregular or infrequent intervals) Activities: Check the digester, particularly Chinese-style digesters, for any gas leaks. Also, examine components in high-technology units such as pumps and mixers, which require occasional repair or replacement.

Finally, preventing sand, dirt, and gravel from mixing with dung as it is being collected, and protecting the dome of the digester with a metal or asphalt coating, will lengthen time between maintenance.

IV. COMPARING THE ALTERNATIVES

CURRENT RESEARCH AND DEVELOPMENT

Biogas Generation Technology

Extensive research continues with the various biogas generation plants operating worldwide. Various institutions throughout the world are conducting research toward making maximum use of the biogas produced. This involves matching energy needs to gas production, and using equipment that burns or converts the gas more efficiently. Additional research deals with digester designs and design parameters; here, heat losses and maintaining an adequate, stable temperature in the digester are of prime interest to researchers in their efforts to maximize methane production. Other research efforts focus on improvements in the use of digester effluent to promote maximum growth of algae, fish, aquatic vegetation, and farm animals.

Competing Technologies

More sophisticated and expensive biomass conversion technologies exist to convert organic material to charcoal, producer gas, crude oil, simple sugars, alcohol, plastics, or other chemicals. Pyrolysis, which may be used to produce crude oil, for example, or distillation, which yields ethyl alcohol, are examples of these technologies. These technologies have been introduced in many developing countries, but further research is required before they can be widely applied.

COMPARISON OF TECHNOLOGIES

This paper focuses on biogasification as a means of producing fuel from material that might otherwise be wasted or that has only a single end use, for example, as fertilizer. The alternative biomass conversion technologies are burning raw waste to get rid of it, composting, distillation, burning raw waste to provide process or other beat, gasification, and pyrolysis. To compare all of these technologies, you must examine each technology separately, weighing its advantages and disadvantages and taking into account such factors as the availability and cost of capital, energy costs, the relative value of a particular raw waste and the end products it produces, the availability of human and material resources, and the impact of the technology on the environment. The discussion below presents some examples of the kinds of factors you need to consider in balancing one technology against another.

If the sole objective is to reduce waste, burning raw waste may be a good choice, provided it is sufficiently dry, air pollution is controlled, and there is a means to dispose of the ash. One disadvantage of burning raw waste for disposal is that it is a very inefficient use of energy. The energy produced by burning is wasted. In some situations, simply making the waste material available to people who can use it for cooking fuel may be a more effective means of disposal. And it does help assure that the heat energy will be put to use.

Composting is an excellent way to turn waste products into a commodity--fertilizer--simply and economically. One disadvantage of composting is that some of the nutrients in the raw waste-- particularly nitrogen, phosphorus, and potassium--convert to a gas, evaporate, and are lost to the atmosphere, or they leach out through the soil. Moreover, composting is limited to producing only fertilizer.

If you want to do more with raw waste than composting or just getting rid of it--that is, if you want to harness the energy from the raw waste material to produce fuels or other products-- you will need to make additional investments in capital, materials, and labor. As we have seen in this paper, a biogas digester yields both a fuel gas and a high quality fertilizer. Unlike composting, the digestion process retains and even improves the nutrient value of the original feedstock. With biogasification, raw wastes can be digested, and returned to the environment in the form of fertilizer and fuel, without degrading the environment. Keep in mind, however, that the equipment (e.g., a digester, systems, pumps) necessary for biogasification will generally be more expensive than the equipment (e.g., a wagon equipped with a loader, a manure spreader) necessary for composting.

The remaining four biomass conversion technologies--distillation, controlled burning to provide process or other heat, gasification, and pyrolysis--collectively produce an even wider range of products than biogasification. Distillation of raw wastes produces sugar and alcohol, for example; controlled burning produces heat to, say, a boiler. Pyrolysis produces biofuels such as charcoal and crude oil; and gasification produces still other biofuels such as low- and medium-energy gas (often called producer gas). These four technologies differ chiefly in their equipment requirements (i.e., depending on the technology, the hardware can be as simple as a cookstove or retort or as intricate as a distillation plant), in their techniques (i.e., some techniques are more complex than others, resulting in higher product yields), and in costs.

In sum, comparing one biomass conversion technology with another must be based on what end products you want from the technology, end product user how much you are willing to spend, relative economies of scale, skill levels, availability of raw waste materials, environmental impact, and many other factors.

V. CHOOSING THE TECHNOLOGY RIGHT FOR YOU

ECONOMIC IMPACT

Economics are a major factor in deciding whether or not to introduce a biogas system. To determine the economics of such a system, you need to consider such factors as availability and cost of biogas (based on BTU), cost of equipment, capital costs, labor costs, energy availability/needs/cycles, material availability and costs, and anticipated returns. Remember, also, to factor into the cost analysis inflation and capitalization expenses. All cost factors and the resulting analysis will vary from country to country.

SOCIAL/CULTURAL IMPACT

Certain social/cultural questions need to be addressed. For example, is daily waste handling acceptable or taboo? Moreover, to succeed, a biogas technology must interface with existing practices: can existing waste management practices be adapted, for example, to include a digester and effluent disposal? What happens to the very poor who have traditionally collected cattle dung freely to use for fuel when the dung is used in a digester and the fuel is available only to those who can pay for it? Who controls the distribution of the gas in a community system?

AVAILABILITY OF RESOURCES

Technical resource considerations include taking into account the availability of a constant, high-quality supply of organic material, the suitability of the ambient temperature, the availability of good-quality water with which to dilute the feedstock, whether the biogas produced can be used efficiently, and whether the space is sufficient for effluent disposal and usage. Moreover, keep in mind the need for a biogas plant, whose construction and operation depend upon the availability of capital, personnel (skilled and semiskilled), and materials.

REGULATIONS

Consult local officials about any local regulations and laws that may prevent you from building or using a biogas generator. On the positive side, some laws might work in your favor. For example, the governments of some developing countries provide investment incentives, grants, or low-interest loans to people who want to introduce a biogas plant. Such governments are actively pursuing national policies that would reduce dependence on imported fuels and so encourage the production of biogas as an environmentally safe fuel source.

LOCAL MANUFACTURE

Chinese- and Indian-style biogas generators can generally be built in-country, since plant components are usually available locally. Certain components, i.e., the dome and guide mechanism of an Indian digester, can be manufactured on a larger scale and sold to users.

SCALE OF PRODUCTION AND POTENTIAL MARKET

Subsistence farmers who depend on firewood for cooking and heating comprise a substantial percentage of the world's population. Though biogas generation seems likely to at least supplement their current energy supplies, there are several reasons why biogas may not totally replace firewood:

* raw waste from the equivalent of several cows is required to meet a family's cooking needs;

* nearly all of the biomass conversion technologies require investments of capital usually available only to a few people in society;

* cultural norms may not permit waste handling or gas usage, or may limit availability of organic material if animals are pastured rather than confined; and

* biogas generation must be accepted and learned, a process dependent on motivated, knowledgeable extension agents or others who can point to successful applications of the technology, or who can demonstrate it effectively.

SOURCES OF INFORMATION ON BIOGAS PLANTS

Director, Gobar Gas Scheme Khadi and Village Industries Commission Gramodaya Irla Road, Vile Parle (West) Bombay 400 056 INDIA

Head of the Division of Soils Science and Agricultural Chemistry Indian Agricultural Research Institute New Delhi 110 012 INDIA

Farm Information Unit Directorate of Extension Ministry of Agriculture and Irrigation New Delhi, INDIA

Gobar Gas Research Station Ajitmal, Etawah Uttar Pradesh, INDIA

Director, National Environmental Engineering Research Institute World Health Organization 1211 Geneva 27, SWITZERLAND

Economic and Social Commission for Asia and the Pacific (ESCAP) Division of Industry, Housing, and Technology United Nations Building Bangkok 2, THAILAND

Bangladesh Academy for Rural Development Comilla, BANGLADESH

Appropriate Technology Development Organization Planning Commission Government of Pakistan Islamabad, PAKISTAN

CEMAT Apartado 1160 Guatemala, GUATEMALA

OLADE Casilla 119 Quito, ECUADOR

Volunteers in Technical Assistance (VITA) 1815 North Lynn St., Suite 200 Arlington, VA 22209 USA

BIBLIOGRAPHY

Barnett, A.; Pyle, L.; and Subramanian, S.K. Biogas Technology in the Third World: A Multidisciplinary Review. IDRC-103e. Ottawa, Ontario, Canada: International Development Research Center, 1978.

Brace Research Institute. MacDonald College of McGill University. A Handbook on Appropriate Technology. Ottawa, Ontario, Canada: Canadian Hunger Foundation, 1976.

Hills, D.J., and Roberts, D.W. "Basic Fundamentals of Methane Generation from Agricultural Waste." Extension service paper, University of California, Davis, 1980.

House, D. The Compleat Biogas Handbook. Aurora, Oregon, 1980.

McGarry, M.G., and Stainforth, J. Compost, Fertilizer, and Biogas Production from Human and Farm Wastes in the People's Republic of China. IDRC8e. Ottawa, Ontario, Canada: International Development Research Center, 1978.

Lichtman, R.J. Biogas Systems in India. Arlington, Virginia: VITA, 1982.

Pohland, F.G., ed. Anaerobic Biological Treatment Processes. Advances in Chemistry Series 105. Washington, D.C.: American Chemical Society, 1971.

Shuler, M.L., ed. Utilization and Recycled Agricultural Wastes and Residues. Boca Raton, Florida: CRC Press, Inc., 1978.

Subramanian, S.K. Bio-gas Systems in Asia. New Delhi, India: Management Development Institute, 1977.

Targanides, P. "Anaerobic Digestion of Poultry Waste." World Poultry Science Journal 19 (1962):252-61.

Tatom, J.W. "Pyrolysis Experience in the Developing Countries." Proceedings, Big-Energy '80 World Congress and Exposition. Washington, D.C.: Bio-Energy Council, 198, pp. 180-85.

SUPPLIERS AND MANUFACTURERS OF BIOGAS PLANT EQUIPMENT AND ACCESSORIES

Patel Gas Crafters Private Limited 1/2, Shree Sai Bazar Centre Bombay 54, INDIA

Santosh Engineers 11 Swami Vivekananand Nagar Varanasi 221 002 INDIA