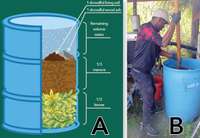

Figure 1. Bioliquid Fertilizer ingredient ratios (A) and the process of mixing (B). Source: Weslee Green (A) and Tim Motis (B)

Bioliquid fertilizer (BLF; also known as organic liquid fertilizer; Figure 1) is popular within ECHO’s network and smallholder farmers around the world. ECHO West Africa introduces and instructs on how to prepare this amendment in ECHO West Africa Note 1 (Sié Kansié, 2017; http://edn.link/y3mrg2). This fertilizer is easier to make than other on-farm amendments such as compost and is easily adaptable. ECHO encourages using locally available manure and plant options. Recognizing a need for information on the nutrient composition of BLF, we (ECHO staff in Florida) created two formulations of BLF and sampled them over time for nutrient analysis. This article summarizes our findings, which shed light on when to apply BLF and nutrient amounts with and without manure.

Two options for generating on-farm bioliquid fertilizer

In March, 2022 we made two different batches of BLF. The first was based on the formula outlined by Sié Kansié (2017) using pigeon manure and the new growth (leaves and stems) of Mexican sunflower (Tithonia diversifolia). The second, simplified formula contained tithonia and water only. Table 1 outlines formula ingredients and proportions.

| Formula | Ingredient | Rough guidelines | Measured weight |

|---|---|---|---|

| Manure-based | Pigeon manure | 1/3 of volume | 25.4 kg |

| Plants (Tithonia diversifolia) | 1/3 of volume | 6.3 kg | |

| Wood ash | 1 shovelful | 0.8 kg | |

| Living soil | 1 shovelful | 2.7 kg | |

| Water | Remainder of volume | 205 L | |

| Tithonia only | Plants (Tithonia diversifolia) | Full container (unpacked) | 0.345 kg |

| Water | Remainder of volume | 18 kg | |

| * Tithonia plant material used for both formulas were primarily leaf tissue and some new shoot growth (Figure 2). | |||

Figure 2. Tithonia plant material used in both formulations. Source: Quinn Beitzel

Results from nutrient analyses

Comparing nutrient content of manure and tithonia raw ingredients

Minerals analyzed, with their abbreviations, are listed in table 2. The local pigeon manure contained 4.0% total N (40 g N/kg manure), 2.7% total P (27 g P/kg manure), and 2.3% total K (23 g K/kg manure) based on dry weight. Our results are comparable to those reported by Chastain et al. (2001) for meat chicken manure (35.5-36 g N/kg manure, 34.5-36 g P/kg manure, and 23 g K/kg manure). Pigeon manure is nitrogen-rich and has a Carbon:Nitrogen (C:N) ratio of 8.24 on average (Villa-Serrano et al., 2010). This low ratio is common among poultry manures because excrement contains both urine and solids. Cattle manure, in comparison, has a C:N ratio of about 20:1 1(Macias-Corral et al., 2019).

The young Tithonia diversifolia leaves used in both formulations contained 4.4% N, 0.7% P, and 2.5% K. Tithonia’s high N content (Motis, 2017) is the primary reason for its use in making natural fertilizers such as compost and BLF. While the N and K content between the two main ingredients (pigeon manure and tithonia) are comparable, pigeon manure has greater P content. Livestock manures are common sources of P, a plant macronutrient needed for root development, photosynthesis, and cell division.

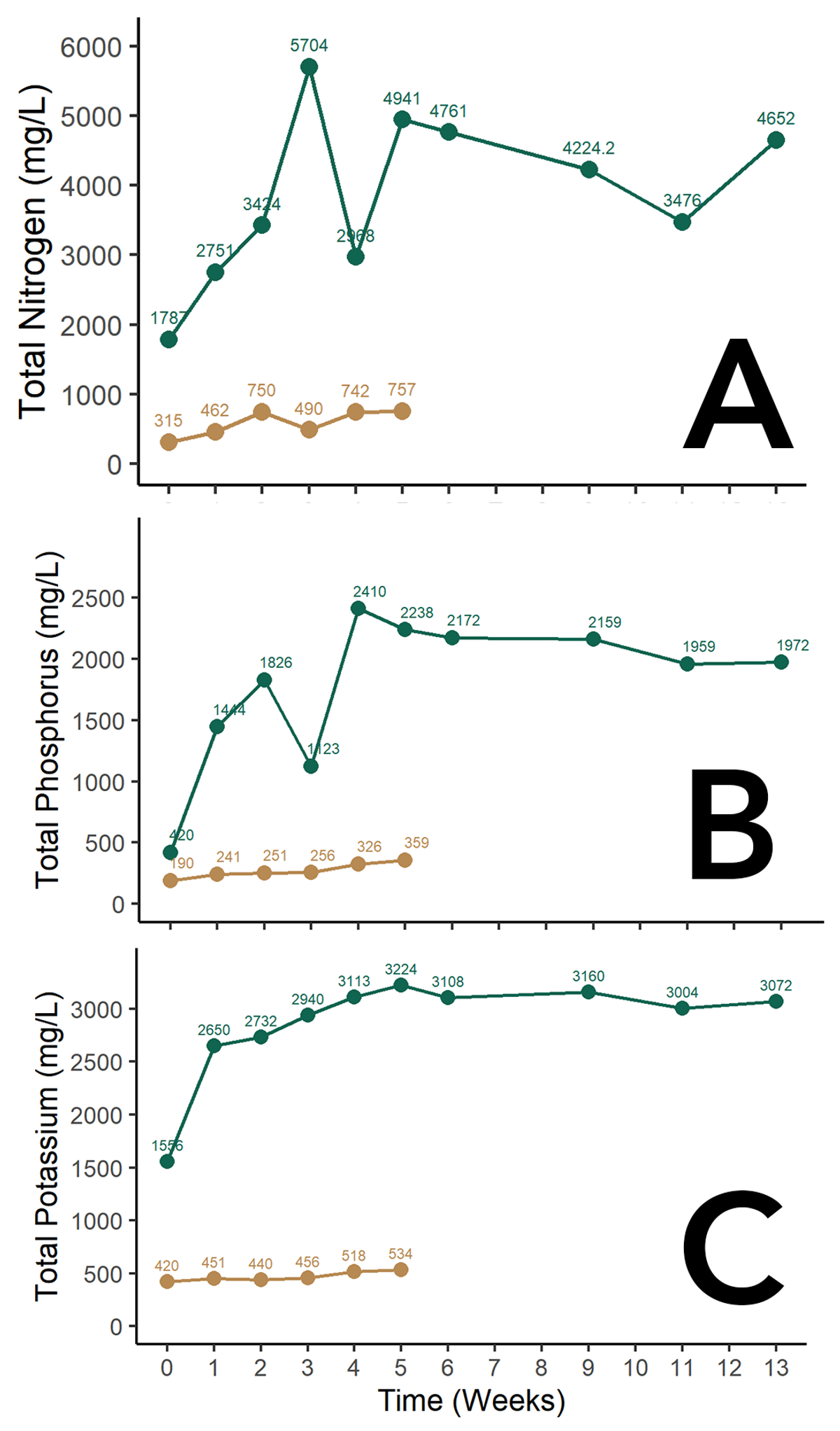

Figure 3. Total N (A), P (B), and K (C) content of the manure-based (green) and tithonia-only (brown) BLF formulations over time. Source: Stacy Swartz

We thoroughly mixed each formula with the ingredients detailed in table 1 until uniform in appearance. The manure-based BLF was covered with a breathable cloth, allowing for aerobic decomposition. The manure-based BLF was mixed daily as outlined by Sié Kansié (2017). The tithonia-only formulation was covered with a plastic lid and was not mixed daily. Each week (including the week of initial mixing: week 0), we thoroughly mixed each formulation and obtained a sample. The tithonia-only liquid fertilizer was sampled for the first five weeks while the manure-based BLF was sampled for thirteen weeks. At each sampling, a bottle of BLF was sent to a laboratory for mineral analysis.

Comparing formulations over time

Figure 3 and table 2 present macronutrient values in mg/L (the equivalent of parts per million, ppm). Nitrogen content of both mixtures increased for the first two weeks after mixing and was optimal at week three for the manure-based BLF (Figure 3A). Phosphorus content increased each week for the tithonia-only formulation but peaked for the manure-based BLF at week four (Figure 3B). Potassium content increased each week for the tithonia-only formulation but peaked for the manure-based BLF at week five (Figure 3C). Average pH for the manure-based BLF was 6.76. Micronutrient and sodium content values are detailed in table 2.

In summary, we saw that:

- Nitrogen levels peaked at two (tithonia) to three (manure-based) weeks after making the fertilizer.

- Most of the other nutrients reached their highest levels at week four or five.

- These trends indicate that the optimum time to apply BLF is earlier (2 to 3 weeks, depending on the formulation) for nitrogen than other nutrients. Factors such as temperature, thoroughness of mixing, and sample handling may have impacted nutrient content values over sampling weeks.

| Macronutrients (mg/L) | Micronutrients (mg/L) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Week |

Type |

Total N |

Total P |

Total K |

S |

Ca |

Mg |

B |

Zn |

Mn |

Fe |

Cu |

Al |

Na |

|

0 |

Manure-based BLF |

1787 |

420 |

1556 |

110 |

456 |

102 |

1.3 |

1.3 |

1.7 |

4.9 |

0.1 |

3.7 |

121 |

|

1 |

Manure-based BLF |

2751 |

1444 |

2650 |

202 |

1658 |

281 |

1.8 |

5.4 |

8.4 |

20.1 |

0.8 |

11.3 |

179 |

|

2 |

Manure-based BLF |

3424 |

1826 |

2732 |

234 |

2132 |

292 |

1.9 |

8.7 |

11.2 |

16.0 |

1.6 |

6.7 |

182 |

|

3 |

Manure-based BLF |

5704 |

1123 |

2940 |

211 |

1329 |

282 |

2.0 |

4.3 |

6.3 |

17.4 |

0.9 |

9.6 |

190 |

| 4 | Manure-based BLF | 2968 | 2410 | 3113 | 529 | 5934 | 777 | 5.7 | 24.6 | 36.7 | 39.7 | 4.9 | 46.1 | 413.9 |

|

5 |

Manure-based BLF |

4941 |

2238 |

3224 |

551 |

5744 |

784 |

6.0 |

23.2 |

34.9 |

13.7 |

4.8 |

39.4 |

426 |

|

6 |

Manure-based BLF |

4761 |

2172 |

3108 |

509 |

5702 |

774 |

5.8 |

23.6 |

33.3 |

25.0 |

4.9 |

41.4 |

405 |

|

9 |

Manure-based BLF |

4224 |

2159 |

3160 |

522 |

5541 |

821 |

6.4 |

23.8 |

31.8 |

84.0 |

5.0 |

48.8 |

427 |

|

11 |

Manure-based BLF |

3476 |

1959 |

3004 |

464 |

5080 |

803 |

5.8 |

23.0 |

27.6 |

76.0 |

4.6 |

43.1 |

404 |

|

13 |

Manure-based BLF |

4652 |

1972 |

3072 |

452 |

5258 |

823 |

6.3 |

22.5 |

25.1 |

80.9 |

4.7 |

24.8 |

410 |

|

0 |

Tithonia-only |

315 |

190 |

420 |

17 |

176 |

124 |

0.8 |

0.0 |

0.0 |

0.0 |

0.0 |

0.1 |

38 |

|

1 |

Tithonia- only |

462 |

241 |

451 |

22 |

213 |

137 |

0.8 |

0.0 |

0.0 |

0.0 |

0.0 |

0.4 |

40 |

|

2 |

Tithonia- only |

750 |

251 |

440 |

23 |

209 |

133 |

0.6 |

0.4 |

0.0 |

0.6 |

0.1 |

0.1 |

38 |

|

3 |

Tithonia- only |

490 |

256 |

456 |

21 |

230 |

143 |

0.6 |

0.2 |

0.2 |

0.5 |

0.1 |

0.8 |

39 |

|

4 |

Tithonia- only |

742 |

326 |

518 |

70 |

589 |

322 |

1.5 |

1.8 |

0.4 |

2.0 |

0.3 |

5.2 |

86 |

|

5 |

Tithonia- only |

757 |

359 |

534 |

79 |

662 |

337 |

1.6 |

2.3 |

0.7 |

2.6 |

0.3 |

1.8 |

87 |

| *Minerals analyzed were nitrogen (N), phosphorus (P), potassium (K), sulfur (S), calcium (Ca), magnesium (Mg), boron (B), zinc (Zn), manganese (Mn), iron (Fe), copper (Cu), aluminum (Al), and sodium (Na). | ||||||||||||||

Application recommendations

Sié Kansié (2017) recommends a dilution of 1:15 to 1:20 2applied near the base of plants 3once or twice a week. Avoid applying too strong of a solution which could be toxic to sensitive plants. To avoid salt buildup or salt-toxicity, use a hand-held TDS meter to confirm overall salt levels in the solution before application. Hoagland’s solution used in hydroponic plant production is a potential benchmark to base dilutions rates on. Hoagland’s solution has around 300 ppm N, so a 5000 ppm BLF formulation could be diluted 15 times to reach close to 300 ppm N. If you are using more plant material than manure, BLF N levels are unlikely to reach higher than 1000 ppm in which case a 1:3 BLF:water ratio is recommended. Even with manure included in the ingredients, nutrients in BLF are not highly concentrated, especially after dilution (e.g., a final concentration of 300 ppm N is only 0.03% N). ECHO uses BLF in combination with other nutrient sources such as compost or NPK fertilizer. Due to microbes and plant hormones that BLF contains, BLF can help plants use fertilizers more efficiently (Eudoxie and Martin, 2019).

Another factor to consider when diluting is the stage of the crop. Young seedlings are more sensitive to leaf burn caused by high salts than more established plants and therefore require more dilution (to lower the amount of BLF in relation to water) early on. Plants entering reproductive stages (flowering and fruiting) require less macronutrients than they did during vegetative stages (leaves and stem growth). After flowering, you could decrease or halt application of the fertilizer entirely.

Network member Tim Tanner (founder of Kilimo Timilifu) has also experimented with using tithonia-only fermented liquid in East Africa for the control of termites! Read more about his methods and experiences in the “Echoes from our Network” article of this issue of EDN.

References

Chastain, J.P., J.J. Camberato, and P. Skewes. 2001. Poultry Manure Production and Nutrient Content. In: Poultry Training Manual (Chapter 3b). Clemson Cooperative Extension.

Eudoxie, G. and M. Martin. 2019. Compost tea quality and fertility. In: Organic Fertilizers - History, Production and Applications [Internet]. https://doi.org/10.5772/intechopen.86877.

Macias-Corral, M.A., J.A. Cueto-Wong, J. Moran-Martinez, and L. Reynoso-Cuevas. 2019. Effect of different initial C/N ratio of cow manure and straw on microbial quality of compost. International Journal of Recycling of Organic Waste in Agriculture 8, 357-365.

Motis, T. 2017. Tithonia for green manure; Seed saving workshop. ECHO Development Notes no. 134.

Sié Kansié, B. 2017. The preparation of organic liquid fertilizer. ECHO West Africa Note no. 1.

Villa-Serrano, A.M, M.D Perez-Murcia, A. Perez-Espinosa, J. Moreno-Caselles, and B. G álvez-Sola. 2010. Characterization and agronomic use of pigeon manure: A case study in the Northeast Transmontano region (Portugal).