VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org

in cooperation with The Committee on Science and Technology for Developing Countries (COSTED) Central Leather Research Institute Adyar, Madras 600 026 India

This publication is one of a series issued by VITA to document the activities of its worldwide Renewable Energy Program.

ISBN 0-86619-167-4

Composed and produced in Arlington, Virginia, by VITA, Inc.

[C] 1983, Volunteers in Technical Assistance, Inc.

Table of Contents

Preface

Abbreviations and Terminology

Introduction

I. Rural Energy Consumption and Biogas Potential

II. An Overview of Biogas Systems

III. Digester Designs

IV. System Operation

V. Gas Distribution and Use

VI. Economic Analysis of a Village System

VII. Village Utilization

VIII. Conclusions and Recommendations

Notes

Appendix

Bibliography

Preface

An important common theme underlies much of the current literature on the application of technology within both developed and developing nations. Any technology has a complex series of impacts on the environment in which that technology operates. The concern over a technology's "appropriateness" is based on the need to determine clearly who will be affected by use of the technology and in what ways.

Behind the concept of "appropriate technology" is the belief that the complex interactions between a technology and its environment should be made "visible." Only then can a technology be evaluated properly. By describing explicitly the impact of a technology, the selection criteria for the technology also become explicit. If we choose a technology that pollutes a river, but which also provides permanent jobs for 10,000 workers, we presumably either value employment benefits over environmental costs or else were ignorant of the pollution effects at the time we made the decision.

The choice of a technology is "appropriate" or "inappropriate" only in the context of the demands we place upon it. The subtle trade-offs between these often conflicting demands are at the real core of any debate over the choice of a technology. Appropriate technology is less a problem of hardware than of appropriate data collection, decision-making, financing, installation, and use--with all the problems of sorting out competing demands and value judgements in each of these tasks.

This study is an assessment of the "appropriateness" of biogas technology in meeting some of the needs of India's rural population. Such an assessment is quite complicated, despite claims that a biogas system is a simple village-level technology. While there is evidence that biogas systems have great promise, they are subject to certain constraints. It is impossible to describe here all the factors that one might study to assess any technology. I only hope that the approach used in this study will help others.

One difficulty in studying biogas technology is the fragmented and often anecdotal nature of the research and development work. In order to provide this snapshot of the state-of-the-art in India, I have had to enlist the aid of a bewildering number of government officials, industrialists, university researchers, missionaries, social workers, journalists, voluntary groups, farmers, merchants, and villagers. While I will never be able to express fully my gratitude to the hundreds of people who have helped me piece this puzzle together, I am particularly indebted to the following: Dr. A.K.N. Reddy, and the ASTRA team, Indian Institute of Science, Bangalore; K.K. Singh, PRAD, State Planning Institute, Lucknow; Dr. Ram Baux Singh, Etawah; T.R. Satishchandran, Energy Adviser, Planning Commission, Government of India; Dr. S. Shivakumar, Madras Institute of Development Studies; Dr. C.R. Muthukrishnan, IIT, Madras; John Finlay and David Fulford of Development and Consulting Services, Butwal Technical Institute, Butwal, Nepal; D. Kumar and M. Sathianathan, Center for Science for Villages, Wardha; Dr. C.V. Seshadri and Rathindranath Roy, Murugappa Chettiar Research Centre, Madras; C.R. Das, Coordinator, Tata Energy Research Institute, Bombay; and the staff at the Central Leather Research Institute, Madras, all of whom were extremely helpful, generous, and patient with a stranger in a strange land.

I am extremely grateful to Dr. S. Radhakrishnan, Scientific Secretary of the Committee on Science and Technology in Developing Countries (COSTED), Indian Institute of Technology, Madras, for his constant trust and financial support throughout the course of my research. John Westley and the staff of the U.S. Agency for International Development (USAID), New Delhi Mission, provided both editing and typing assistance, as well as a research grant (USAID/India Purchase Order IN-P-O-67). The staff of Volunteers in Technical Assistance (VITA) spent many long hours editing the final manuscript and bringing it out in its present form. Of course, the views expressed in this study are my own, and do not represent the official position of VITA, USAID, the U.S. Government, or any other body.

Finally, I am deeply indebted to Dr. Y. Nayudamma, Distinguished Scientist, Central Leather Research Institute, Madras. without his guidance, friendship, and unyielding support, none of this would have been possible. All of these individuals have immeasurably deepened my understanding of biogas technology, as well as of India itself. Any errors or omissions contained in this study are due to my own failure to utilize their considerable insights.

Robert Jon Lichtman December 1982

Abbreviations and Terminology

BHP = brake horsepower

crore = 10,000,000 rupees

hr = hour

kcal = kilocalorie (1,000 calories)

kwh = kilowatt-hour

lakh = 100,000 rupees

[m.sup.3] = cubic meter

MT = million tonnes

MTCR = million tonnes of coal replacement

Rs = Indian rupee(s)

tonne = metric ton (1,000 kg)

Rs 1.00

US$0.125 at the time of this study

Introduction

The term "biogas" system is somewhat of a misnomer. Though biogas systems are often viewed as an energy supply technology, the Chinese regard their systems primarily as a means to provide fertilizer and the sanitary disposal of organic residues. Gas is considered a useful by-product.(1) In India, interest in biogas is due to its potential as a fuel substitute for firewood, dung, kerosene, agricultural residues, diesel, petroleum, and electricity, depending on the particular task to be performed and on local supply and price constraints. Thus, biogas systems provide three primary products: energy, fertilizer, and waste treatment. For the sake of convenience, the term "biogas system" in this study will refer to the technology of digesting organic wastes anaerobically to produce an excellent fertilizer and a combustible gas, and to dispose of agricultural residues, aquatic weeds, animal and human excrement, and other organic matter.

While use of biogas systems is not restricted to rural areas, the difficulties of retrofitting such systems in urban areas, supplying a balanced charge of biomass, generating adequate pipeline pressure, and minimizing capital costs all suggest that biogas systems will be more easily adapted, in the short term, to rural areas. This study therefore is focused on rural utilization of biogas systems.(2) I. Rural Energy Consumption and Biogas Potential

Biogas has great potential for supplying energy for cooking, lighting, and small-scale industry in rural India. This section will show through a series of calculations that biogas theoretically can play a significant, if not major, role in meeting many of these needs, as well as in supplying fertilizer and helping to solve other development problems. Readers not interested in these calculations should skip to Section II on Page 11; the important point is that biogas holds considerable promise and deserves further study.

To assess properly the potential of biogas systems for meeting a variety of rural needs, one would have to know the total amount of organic material (biomass) available annually; that is, material for which there are no other more productive uses. Biomass that could be employed as feed material would have to be studied carefully with respect to the annual output of each material, the average biogas yield per unit of material, collection and transportation costs, and the availability of the material over time.

Unfortunately such data do not exist in India with any degree of reliability. No accurate data exist on the annual supply of water hyacinth, congress grass, banana stems, and other biomass that can serve as a feed material to a biogas system.

Since many agricultural residues are used as fodder, knowledge of the net availability of these residues is important to avoid conflicting demands on their use. Statistics on the amount of residue per crop, though available, tell nothing of the end use of the residue. Revelle cites aggregate figures of 34-39 MT of crop residues consumed annually as fuel.(3)

Even annual dung output is a matter of some controversy. Desai estimates that out of the 114-124 MT (dry weight) of dung produced annually, about 36 MT dry weight are burned as fuel.(4) The Working Group on Energy Policy calculates that 73 MT of dung are used as fuel,(5) without specifying if this is a dry weight figure (dry weight = approximately 1/5 of wet weight). Revelle uses a World Bank estimate of 68 MT burned as fuel (out of a total of 120-310 MT) and suggests that 83 percent of this, 56 MT (dry weight), is consumed in rural areas.(6)

The Indian Ministry of Agriculture offers data on livestock Population and dung voided per animal per annum as shown in Table I-1. Again, there is uncertainty about the percentage of dung produced in rural areas. To be conservative, we will assume that there are roughly 237.5 million cattle, buffalo, and young stock (from Table I-1), and that their collectible daily yield from night droppings (when cattle are tied up near a dwelling) is approximately 8.0 kg per head.(7) Using Revelle's estimate of rurally produced dung at 83 percent of the total, annual rural dung production would be over 575.6 MT wet weight, or 115.1 MT dry weight.

Various estimates shed little light on the percentage of dung collected, or on factors affecting dung output, such as cattle species, body weight, diet, etc. Data will also vary regionally and seasonally. If we assume that there is a 20 percent weight loss during collection of the 115.1 MT dry weight of rural dung (calculated above), then the net available dung is 92.1 MT. To this can be added 34 MT dry weight of crop residues that are burned annually. This gives a total of about 126 MT (dry) of biomass that is available for biogas systems. Assuming an average gas yield of 0.2 [m.sup.3]/kg (dry) for the biomass(8) and a calorific value of 4,700 kcal/[m.sup.3] for biogas(9), the available biomass would yield roughly 25 billion [m.sup.3] for biogas. This is

Table I-1 Potential Annual Availability of Dung (1972)(10)

Annual Number of Daily Output/hd. Total Animals Output/ (millions (millions Livestock (Millions) Head (kg) of tonnes) of tonnes)

Cattle 131.4 10 3.65 479.6 (3 + years old)

Buffalo 37.8 10 3.65 138.0 (3 + years old)

Young stock 68.3 3.3 1.20 82.0

Sheep and goats 108.4 1.1 .4 43.4

TOTAL 743.0 Total = 743 MT (wet weight)

Total minus 20 percent collection loss = 594.4 MT (wet weight) = 118.9 MT (dry weight)

equivalent to 118 trillion kcal. This estimate probably is low, because it does not include numerous weeds and aquatic biomass that might be used as a feedstock for biogas plants, but which currently have no alternative uses.

Assuming biogas burners have a thermal efficiency of 60 percent, the potential net energy for cooking from biogas is roughly 71 trillion kcal per annum. Approximately 975 trillion kcal are currently consumed during the burning of dung, firewood, charcoal, and crop residues for domestic use (cooking, water heating, etc.).(11) Of that figure, 87 percent is used in cooking.(12) Therefore, approximately 848 trillion kcal per annum is consumed in cooking in rural India. This figure, when combined with a 10 percent average thermal efficiency of "chulahs"(13) (mud/clay stoves) and the vast number of open cooking fires, gives a net energy consumption of approximately 85 trillion kcal per annum for cooking. We will assume that rural cooking needs consume about 85 percent of this figure, so that the annual net energy consumption for rural areas is 72.3 trillion kcal. Thus, biogas can essentially provide the net usable energy currently consumed in cooking from all noncommercial fuel sources in rural India.

The amount of total solids in biogas slurry prepared from 126 billion kg (dry weight) of organic matter, the minimum amount annually available for fuel and fertilizer (from our previous calculations), is roughly 630 billion kg (wet weight), assuming for simplification that both plant wastes and dung contain 20 percent solids.

Given current practices, this biomass would be mixed with water at a 1:1 ratio if it was to be fed into a biogas system. The total influent would weigh 1.2 trillion kg. Twenty percent of this would be lost during microbial digestion. Of the remainder, the percentage of total solids per kg of weight of slurry would be about 6.4 percent. The digested biomass thus would contain 61 MT of solids.

Table I-2 shows the relative fertilizer content of biogas slurry and farmyard manure.(14) Based on this table, 61 MT of the total solids in biogas slurry would yield approximately 1.037 MT of nitrogen (N), .976 MT of phosphorus pentoxide ([P.sub.2][O.sub.5]), and .610 MT of potassium monoxide ([K.sub.2.O]) per annum.

Without a more detailed picture of the current end uses of organic residues, it is difficult to assess accurately the potential impact of a large-scale biogas program on overall fertilizer supply. Importation of chemical fertilizer is a function of the gap between demand and domestic production. Domestic production is comprised of indigenous production of chemical fertilizers and the use of organic residues and wastes that are composted as farmyard manure. Any net increase in the

Table I-2 Average Fertilizer Value of Biogas Slurry and Farmyard Manure

(Percentage of dry weight)

Substance N [P.sub.2][.O.sub.5] [K.sub.2.O] Total

Biogas slurry 1.7 1.6 1.0 4.25

Farmyard manure + compost 1.0 0.6 1.2 2.8

amount of fertilizer derived from organic residues can be used to offset imports, assuming of course that domestic production of chemical fertilizers remains constant. The net increase in available fertilizer attributable to biogas slurry is derived from the following calculations:(15)

a) [F.sub.n] = [F.sub.ba] + ([F.sub.fyma] - [F.sub.fym])

where:

[F.sub.n] = the net increase in fertilizer

[F.sub.ba] = fertilizer value of currently burnt biomass, if it was digested anaerobically instead.

[F.sub.fyma] = fertilizer value of biomass currently composted as farmyard manure, if it was digested anaerobically.

[F.sub.fym] = fertlizer value of biomass currently composted as farmyard manure.

b) Surveys from 13 states during 1962-69 found that 72 percent of total dung is collected on an average from urban and rural areas. When this figure is combined with earlier calculations, we find that 92.1 MT of rural dung (dry weight) X 72 percent = 66.3 MT of dung (dry weight) that is actually used as manure in rural areas each year. An estimated 10 MT (dry weight) of a possible 34 MT of agricultural residues are added to this. This produces a total of 76.3 MT of dung and agricultural residues that currently are being used for fertilizer in rural areas. The remaining 25.8 MT of dung and 24 MT of agricultural residues, or a total of 49.8 MT (dry weight), currently are consumed as fuel, assuming the same rate of collection and distribution as explained above.

c) Using the calculations from (b) above and Table II, the values for [F.sub.ba], [F.sub.fyma], and [F.sub.fym] are shown below. Values are in MT:

N [P.sub.2][O.sub.5] [K.sub.2.O] _____ _______ _______

[F.sub.ba] .847 .797 .498

[F.sub.fyma] 1.297 1.221 .763

[F.sub.fym] .763 .458 .916

d) Therefore, the net increase in fertilizer due to digesting available organic material in biogas is approximately:

[F.sub.ba] + ([F.sub.fyma] - [F.sub.fym]) = [F.sub.n] (a)

.847 + (1.297 - .763) = 1.381 MT of N.

.797 + (1.221 - .458) = 1.560 MT of [P.sub.2][O.sub.5]

.498 + (0.763 - .916) = .345 MT of [K.sub.2]O

In 1979-1980, 1.295 MT of N, .237 MT of P, and .473 MT of K were imported at a cost of Rs 887.9 crores with additional subsidies of Rs 320 crores.(16) While our calculations show the enormous potential of biogas slurry in meeting domestic fertilizer needs, it must be noted that to organize such an effort would be a massive task. Manure would have to be collected from very diffuse points and transported to farms as needed. Fertilizer requirements will increase dramatically as India's population approaches one billion people shortly after 2000 A.D., including an increased demand for chemical fertilizers. Organic fertilizers from the slurry of biogas systems could certainly contribute to fertilizer supply needs. Our analysis is probably somewhat understated in that, as additional residues will be available from increased crop production, a potential increase in cattle population or improved cattle diet will mean more dung. Also, a variety of organic materials such as water hyacinth, forest litter, and other under-utilized biomass could all be digested, increasing the fertilizer derived from biogas slurry.

The above discussion is intended only to illustrate the order of magnitude of the potential impact of large-scale utilization of biogas systems. Much of the data used were aggregated from small and often inaccurate sample surveys, causing considerable margins of error. This problem will be discussed further at the end of this section.

Additional insight into the potential contribution of biogas systems can be obtained from recent projections of rural energy demand. Commercial and noncommercial energy demand, based on the Report of the Working Group on Energy Policy, is shown in Table I-3.

This data is the basis of the Reference Level Forecast of the study, an extrapolation of current trends. It is interesting to note that the household sector (90 percent of India's households are in rural areas) is assumed to account for almost all noncommercial fuel consumption throughout this period, except for 50 MTCR of firewood, agricultural residues, and bagasse that are used in industry. The Working Group also suggests that noncommercial fuels, as a percentage of total household demand, will gradually decline from the current 83.9 percent to 49.7 percent, and that the percentage of the total noncommercial fuel demand in all of India will drop from 43.5 percent to 11.5 percent.

Table I-3 Reference Level Forecast Energy Demand (1976 - 2000) In Household and All-India In Millions of Tonnes of Coal Replacement (MTCR)(17)

Commercial Fuels MTCR (percent of total)

1976 1983 2000 _____________ ______________ ______________

Household 37.4 (16.1) 51.6 (20.2) 165.5 (50.3) All-India 252.7 (56.5) 390.2 (65.7) 1,261.3 (88.5)

Non-Commercial Fuels MTCR (percent of total)

1976 1983 2000 _____________ ______________ ______________

Household 194.6 (83.9) 204.1 (79.8) 163.5 (49.7) All-India 194.6 (43.5) 204.1 (34.3) 163.5 (11.5)

Note: Indian coal contains 5,000 kcal/kg.

The Working Group does not view this situation as desirable, and offers an Optimal Level Forecast based on a series of policy recommendations. This is shown in Table I-4.

For this optimistic projection to be realized (assuming total demand remains the same), commercial fuels will need to be substituted increasingly by noncommercial fuels. By 1983, noncommercial demand for all-India must increase by 1.3 MTCR over present projections.

Table I-4 Optimal Level Forecast(*) Energy Demand (1982 - 2000) For Household Sector and All-India In Millions of Tonnes of Coal Replacement (MTCR)(18)

Commercial Fuels MTCR (percent of total)

1983 2000 _____________ ______________

Households 51.6 (20.0)() 134.3 (41.0)() All-India 388.9 (65.4) 1,017.8 (71.3)

Non-Commercial Fuels MTCR (percent of total)

1983 2000 _____________ ______________

Households 204.1 (80.0) 194.7 (59.0) All-India 205.4 (34.6)(*) 407.0 (28.7)(*)

(*) Note: The author has calculated commercial fuel demand for households and non-commercial fuel demand for All-India on the assumption that the Reference Level Forecast total demand for each category remains constant. A relative increase in demand for commercial fuels would cause a relative decrease in demand for non-commercial fuels. Conservation measures would reduce overall demand, and thus reduce the amount of non-commercial fuels needed to bridge the gap between supply and demand.

The actual figures are not included in the Report of the Working Group on Energy Policy.

By the year 2000, the household noncommercial fuel demand must increase by 31.2 MTCR, and noncommercial fuel demand in all of India must increase by 273.5 MTCR if commercial fuel consumption is to remain at the level suggested in the Optimal Forecast (without additional conservation).

Though these projections can be criticized for relying on suspect sample data(19) or questionable assumptions,(20) The Report of the Working Group nonetheless shows clearly that an increase in energy from noncommercial, renewable resources is a high priority. The report specifically describes biogas systems as "the most promising alternative energy technology in the household sector," although it does not minimize some of the problems associated with the technology.(21)

The optimal level forecast for irrigation and lighting (based on a series of recommended conservation measures) is shown in Table I-5.

Table I-5 Electricity and Diesel Demand: Irrigation and Rural Lighting (1976 - 2000)(22)

Increase 1978 1983 2000 1978-2000 IRRIGATION

Diesel 2.6 4.6 6.6 + 4.0 (billion liters)

Electricity 14.2 16.0 28.0 +13.8 (billions of KWH)

HOUSEHOLD ELECTRICITY 4.4 10.7 32.2 +21.5 (billions of KWH)

(With rural (3.7) (9.6) (29.0) (+25.3) households at 90 percent of total)

Total Rural 17.9 25.6 57.0 +39.1 Electric Demand (billions of KWH)

NOTE: Electric pumps consume approximately 3,000 KWH/year/ pumpset (at about 5 HP/pumpset).

Diesel pumps consume approximately 1,000 liters (.8 tonnes) of diesel fuel/year/pumpset.

In 1978-1979, an estimated 360,000 electric pumpsets and 2.7 million diesel pumps were used for irrigation. Future growth is projected to increase to 5.4 million electric pumpsets and 3.3 million diesel pumps by 1983. The estimated ultimate potential of 15.4 million energized wells optimistically is reached by the year 2000, when there will be 11 million electric pumpsets and 4.4 million diesel pumps in operation. Animal-power lifting devices are expected to decline from around 3.7 million in 1978 to 660,000 by the year 2000.(23)

As shown in Table I-5, the total increase in projected diesel fuel demand for irrigation between 1978-2000 is 4 billion liters or 16 billion BHP-hrs, since .25 liters of diesel generate 1 BHP-hr. For the same period, rural electricity demand (irrigation and household lighting) is expected to increase by 39.1 billion kwh. Modified diesel engines can run on a mixture of 80 percent biogas and 20 percent diesel. Since .25 liters of diesel = 1 BHP, .05 liters can be mixed with .42 [m.sub.3] of biogas to generate the same power. Using a conversion factor of 1 BHP = .74 kwh, .07 liters of diesel mixed with .56 [m.sub.3] of biogas will generate 1 kwh.(24) Therefore, the 16 billion BHP-hrs required by the year 2000 to run diesel pumpsets could be supplied by a little over 6.7 billion [m.sub.3] of biogas and .8 billion liters of diesel fuel. Alternatively, the 39.1 billion kwh required for rural electricity needs could be supplied by 21.9 billion [m.sup.3] of biogas and 2.74 billion liters of diesel fuel.

We have previously calculated that at least 25 billion [m.sub.3] of biogas is potentially available from current patterns of biomass use. If, and it is a big "if", an alternative cooking fuel could be supplied to those areas that presently rely on dung and plant wastes, perhaps with fuelwood plantations, this biomass could be shifted toward meeting a large share of increased demand for commercial fuels in rural areas. Since food production and cattle population will have to increase to keep pace with population growth, the amount of available biomass, and hence biogas, will expand similarly. The total increase in rural commercial fuel demand could be met by a mix of 28.6 billion [m.sub.3] of biogas and 3.6 billion liters of diesel, which is less than the 4 billion liters projected in Table I-5. Such a substitution seems well within the range of technical possibilities.

Some of the economic aspects of substituting biogas for diesel and electricity are discussed in section VI. In many villages, the costs of connection to the nearest central grid are prohibitive even if the load were increased to include lighting, pumpsets, etc.(25) For some areas, biogas may represent the only viable technology, whether or not the gas is burned directly or converted to electricity. As the Working Group notes, despite the fact that roughly half of India's villages are electrified, population increases have kept the percentage of total households that are electrified relatively constant at 14 percent. Within "electrified" villages, only 10-14 percent of the houses obtain electricity for household applications. Only 5 percent of rural houses use electricity for lighting because rural family incomes cannot support the high installation cost of electricity.(26)

As an alternative, a benefit of a large-scale biogas program could be to free up the millions of tonnes of firewood that are consumed annually for cooking. Using the Working Group on Energy's norm of 1 MT of firewood (all types) = .95 MTCR, this represents almost 66.8 MTCR, which is over 30 percent of the increased demand for noncommercial fuels, or 10 percent of the increased demand for commercial fuels in the optimal level forecast for the year 2000. While the actual use of this vast amount of energy would depend on the economic, social, and managerial constraints associated with various thermal conversion processes, the possibilities for converting this energy into electricity, gas, or pyrolytic oil deserve serious consideration.

Before biogas could be used as a substitute for commercial fuels, a number of complex energy demand, investment, and development issues would need to be analyzed carefully. Such an analysis is far beyond the scope of this study. Nevertheless, it is in India's interest to raise these questions since there are many different energy supply mixes that are technically possible, given India's resources. The preceeding discussion is intended only to show the magnitude of the potential contribution that biogas systems could make to India's energy and fertilizer needs.

A number of technical, political, and organizational problems must be solved before a large-scale biogas program can be undertaken. The remainder of this study is devoted to exploring these problems in some detail. II. An Overview of Biogas Systems

Most biogas systems consist of a basic series of operations, which is described briefly in this chapter. There may be certain variations or additions to this basic schematic design, especially if the system is integrated with other "biotechnologies," such as algae ponds or pisciculture, or if additional uses can be found for carbon dioxide ([CO.sub.2]) that is present in biogas. A brief description of the different aspects of a biogas system is necessary before discussing the economic and social dimensions of the technology.

RAW MATERIAL (BIOMASS) COLLECTION

Almost any organic, predominantly cellulosic material can be used as a feed material for a biogas system. In India, the Hindi name for these systems, "gobar" (dung) gas plants, is imprecise. This is shown by the following list of common organic materials that may be used in gobar gas plants:(27)

* algae * animal wastes * crop residues * forest litter * garbage and kitchen wastes * grass * human wastes * paper wastes * seaweed * spent waste from sugar cane refinery * straw * water hyacinth and other aquatic weeds

Table II-1 on the following page shows some laboratory yields associated with different biomass. It is important to remember that the amount of gas produced from different kinds of biomass depends on a number of variables. The most important of these include the temperature and the amount of time that the biomass is retained in the digester, which is called the loading rate. Unless stated otherwise, all biomass has been tested at 35 [degrees] C and retained for a 35-day period.

Despite the obvious sanitation benefits of feeding human feces into a biogas digester, this practice produces a per capita daily gas yield of only about .025 [m.sup.3]. This means that the excrement from perhaps 60 people would be needed to provide enough gas for the cooking needs of a family of five people. In addition, excessive slurry dilution can result from uncontrolled

Table II-1 Gas Yields for Selected Organic Materials(28)

Material Gas yield in [m.sup.3]/kg of volatile solids, cattle dung .20 human feces, .45 banana stems, .75 water hyacinth, .79 eucalyptus leaves .89 rinsing in a community latrine, since all the latrine water will enter the digester. Corrosive hydrogen sulfide ([H.sub.2]S) is more prevalent in human waste than in animal dung. This may adversely affect engines run on the biogas unless the gas is passed through iron filings for purification. Nevertheless, the role of human enteric pathogens in the communication of disease is well established. Therefore, latrines could be incorporated into a biogas system, provided they are accepted by villagers, affordable, not disruptive of the digestion process, and not harmful to any engine operation. Safe procedures for handling both influent and effluent also must be developed. More research is needed to understand the effects of different combinations of temperatures and retention times in killing harmful pathogens that could remain in the digested slurry.

Water hyacinth is particularly appealing because it is not used as animal fodder, and therefore does not present any "food or fuel" choices. In addition to its higher gas yield, water hyacinth produces gas that appears to have a greater methane content and more soil nutrients than digested dung. However, there are some drawbacks to using water hyacinth. One is that its water requirements are vast. Through transpiration from its leaves, hyacinth absorbs from three to seven times the amount of water that would normally be lost to surface evaporation from the water occupied by the hyacinth. Water hyacinth also can become a breeding ground for mosquitoes and snails, although these can be controlled by introducing predator fish.(29)

There are certain annoyances associated with the use of this and other plant materials. Younger plants yield more gas than older plants, which may necessitate greater discrimination in the manner in which biomass is collected. Plants may have to be dried and shredded to ensure proper mixing, dilution, and digestion. It may often be necessary to add urine to maintain a proper carbon to nitrogen (C/N) ratio. There have been many field reports of scum build-up, clogged inlet tanks, and toxicity to methanogenic bacteria (due to the "shock" caused by the introduction of different biomass materials). However, these reports are sketchy, and the problems could be due to improper digester design or operation. Water hyacinth is almost always mixed with dung; there is little reliable field experience using water hyacinth as the sole input, although this has been done successfully in laboratories, as will be discussed shortly.

Several Indian research groups have been experimenting with "bio-dung"--a fuel cake and/or biogas feed material made from dried and partially composted organic matter of varying combinations.(30) Excellent gas yields have been reported with this still experimental idea, but documentation is insufficient. Nonetheless, this practice of "partial digestion" of the biomass in plastic bags seems similar to the 10-day "predigestion" period observed in China, where organic material is composted prior to batch loading in family digesters.(31) The Chinese report faster gas production if material is partially digested. The process probably reduces the [CO.sub.2] present in the early phases of digestion by simply releasing it in the atmosphere as the gas percolates up through the compost pits.

There are many advantages claimed by proponents of "bio-dung," such as its greater gas yield, higher calorific value, potential for generating revenue as a saleable product, eradication of harmful weeds, and making family-scale digesters affordable to those who own fewer than three to four cattle. There is little evidence currently available to evaluate these possibilities.

MIXING AND FEEDING RAW MATERIAL INTO THE DIGESTER

There has been a good deal of experimentation with the digestion of organic materials in various combinations. Regardless of the biomass used, it must be loaded without being diluted excessively with water. Most researchers mix fresh dung and/or sun-dried organic matter with water at roughly a 1:1 ratio. If the plant matter is still green or the cattle diet is rich in straw, the ratio should be changed slightly to about 1:0.8. Materials should have a C/N ratio of roughly 30:1 due to the digestive requirements of methanogenic bacteria. The relative proportions of different material should be adjusted to maintain this ratio.(32)

The inlet tank can become clogged when assorted feeds of different sizes and composition materials are mixed. Fibrous material can be shredded to avoid this. Different digester designs, incorporating larger inlets, may alleviate this problem Most Indian systems work best if the biomass and water are mixed thoroughly in the inlet tank prior to injection into the digester. Many of these inlet tanks have a removable plug to block the inlet pipe during mixing. Alternatively, the Chinese seem to use less water and spend less time mixing material. This is perhaps due to their batch feeding process, which eliminates the need to add slurry daily.(33)

DIGESTION (34)

Anaerobic digestion consists broadly of three phases:

1. Enzymatic hydrolysis--where the fats, starches, and proteins contained in cellulosic biomass are broken down into simple compounds.

2. Acid formation--where acid-forming bacteria break down simple compounds into acetic acids and volatile solids.

3. Methane formation--where methanogenic bacteria digest these acids and solids and give off [CH.sub.4], [CO.sub.2], and traces of [H.sub.2]S.

Any remaining indigestible matter is found in either the "supernatant" (the spent liquids from the original slurry) or the "sludge" (the heavier spent solids). These two products are often described as "slurry" because the influent in most Indian plants is diluted with water at about a 1:1 ratio to form a relatively homogenous, liquid-like mixture. In China, the supernatant and sludge generally settle into separate layers in either the digester itself or in the output tank, and are removed separately by buckets that are lowered to different depths.

During the first phase of digestion, a great deal Of [CO.sub.2] is produced and pH drops off to roughly 6.2 (pH values of less than 6.2 are toxic to the bacteria needed for digestion). After about ten days, pH begins to rise, stabilizing at between 7-8. Temperatures below 15 [degrees] C (60 [degrees] F) significantly reduce gas production. During the winter months, many family-scale biogas systems in northern India reportedly produce only 20-40 percent of their summer yields. Similarly, Chinese plants often produce almost no gas during winter, and more than half the annual energy required for cooking must be provided by burning crop residues directly. However, the need for a backup source of energy to supplement a biogas system can probably be eliminated with some of the design modifications suggested in the next section. Higher temperatures generally increase gas production, reduce retention time, and increase loading rates, once the bacteria adjust to the warmer environment. Mesophilic bacteria favor temperatures near 35 [degrees] C (95 [degrees] F). Thermophilic bacterial strains are found in the 50-60 [degrees] C (122-140 [degrees] F) range. The addition of nitrogen-rich urine seems to aid in gas production during winter, especially when it is combined with plant wastes. Digesting the wet straw flooring from cattle sheds, if available, is a convenient way to add urine to the influent.

The microbial population of methanogenic bacteria will decrease as slurry flows out from the digester. These bacteria have a doubling rate of roughly 40 hours. However, this slow growth rate can be overcome by greatly increasing the microbial population. There has been informal discussion among experts about a process, reportedly developed in Belgium, that uses a membrane to retain the methanogenic bacteria inside the digester. Gas yield per kg of biomass reportedly increases by a factor of 5-10 when the membrane is used. If these claims can be documented, and if the membrane is both affordable and durable, it would be an important development. There also is sketchy evidence that methanogenic bacteria are pressure sensitive. This might be a problem in some fixed dome systems, which can generate pressure above a water column of 80-90 cm. More research is needed on this point.

The effect of animal diet on gas yield has received far less attention than it deserves. Cattle can be either well fed or near starvation, depending on the income of a farmer and the time of year. Farmers often barely maintain their cattle until just prior to plowing season, when the diet is increased to fatten the cattle for work. Obviously, the less an animal eats, the less dung it produces. The more cellulose, especially in fibrous materials, that it eats, the greater the gas yield will be. More research is needed to determine the optimal diet for cattle given their use as a source of milk, motive power, and combustible energy (biogas), and also considering local resources, available capital, and knowledge constraints.(35) Even without this research, however, it is clear that diet, grazing habits, and costs of collection will greatly affect the net available dung yield per animal.

Many statistics quoted in the literature simply may not apply to a particular locale. These include data on dung yield of animals, gas yield of dung, temperature, the nature and nutrient content of other materials digested, and the [CH.sub.4] content, which can vary 50-70 percent for a given quantity of biogas, depending on diet. Inaccuracies usually manifest themselves in an overestimation of gas availability and overall benefits. Norms mentioned in numerous studies are useful guides to these questions but cannot replace micro-analysis.

A great deal of research is furthering our understanding of the microbiological aspects of biogas systems.(36) If gas yield could be increased and retention time reduced, production costs would decrease, since a smaller volume of biomass per cubic meter of gas would be required. Some of the areas or research include ways to increase the growth rate of methanogenic bacteria, improve the digestibility of lignin, develop microbiological. innoculins that would increase gas production, develop bacterial strains that are less sensitive to cold weather, identify micro-organisms involved in digestion, and separate acid-forming and methanogenic bacteria. As of the writing of this study, there have been no major documented performance breakthroughs achieved as a result of this research.

III. Digester Designs

There are many ways to design biogas systems. The designs discussed in this study are by no means the only possibilities. They either have been tested extensively or were in the midst of serious research and development during the writing of this study. Groups attempting to develop their own systems should use the illustrations in this section only as guides. The characteristics and costs of labor, construction materials, land, etc., will vary according to local conditions and the end uses of the system's gas and slurry.

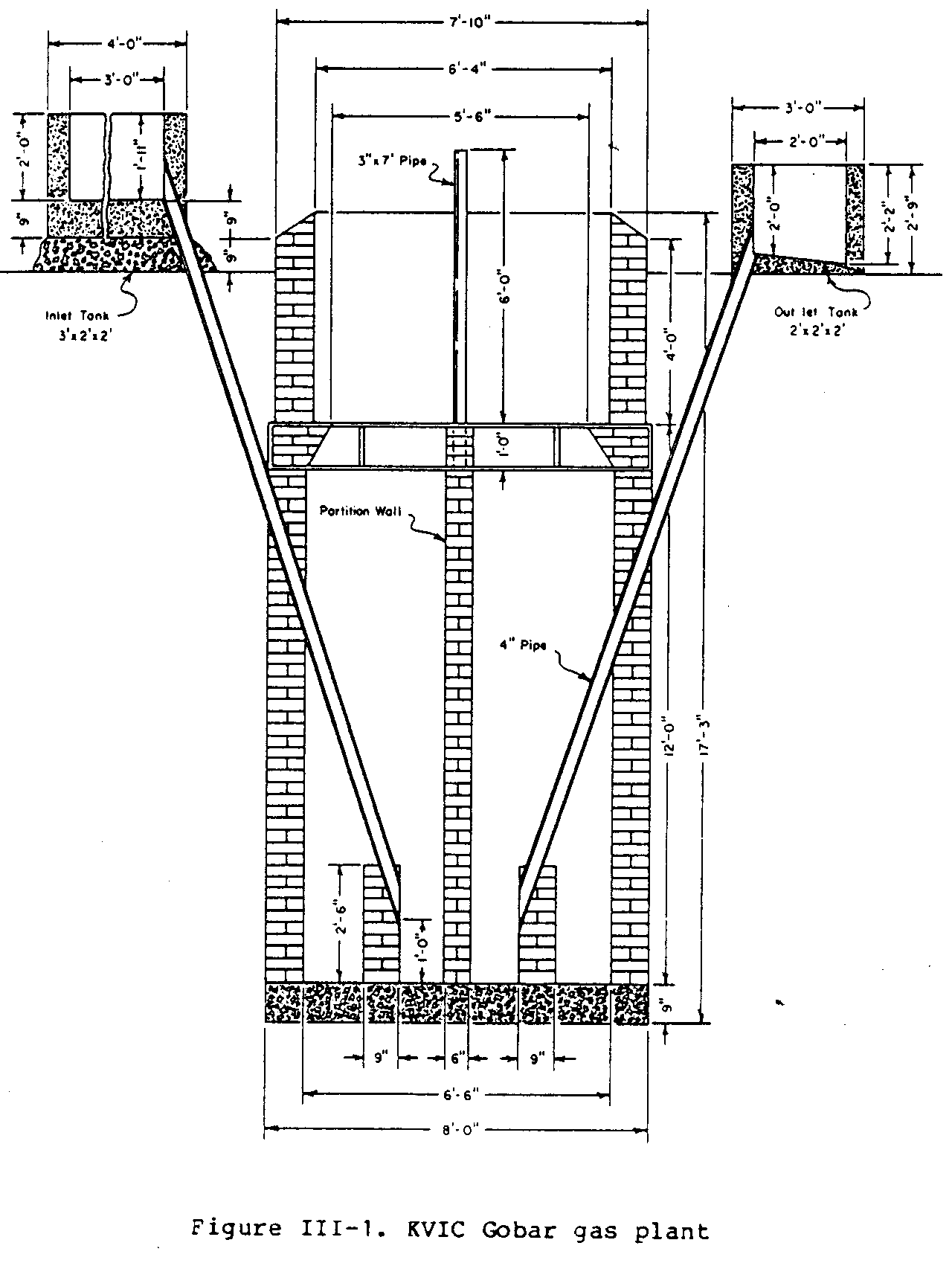

The Khadi and Village Industries Commission (KVIC) design has been developed over the past 15 years and is similar to the

majority of systems currently operating in India (see Figure III-1).(37) As of 1981, KVIC claims to have built about 80,000 of these systems, although there are no reliable data on how many of the units are actually operating, temporarily shut down, or nonfunctioning. The KVIC system consists of a deep well and a floating drum that usually is made of mild steel. The system collects the gas and keeps it at a relatively constant pressure. As more gas is produced, the drum gas holder rises. As the gas is consumed, the drum falls. Actual dimensions and weight of the drum are functions of energy requirements. A long distribution pipeline that might necessitate greater pressure to push gas through its length would require a heavier drum, perhaps weighted with concrete or rocks. Biomass slurry moves through the digester because the greater height of the inlet tank creates more hydrostatic pressure than the lower height of the outlet tank. A partition wall in the tank prevents fresh material from "short circuiting" the digestion process by displacement as it is poured into the inlet tank. Only material that has been thoroughly digested can flow up and over the partition wall into the outlet tank.

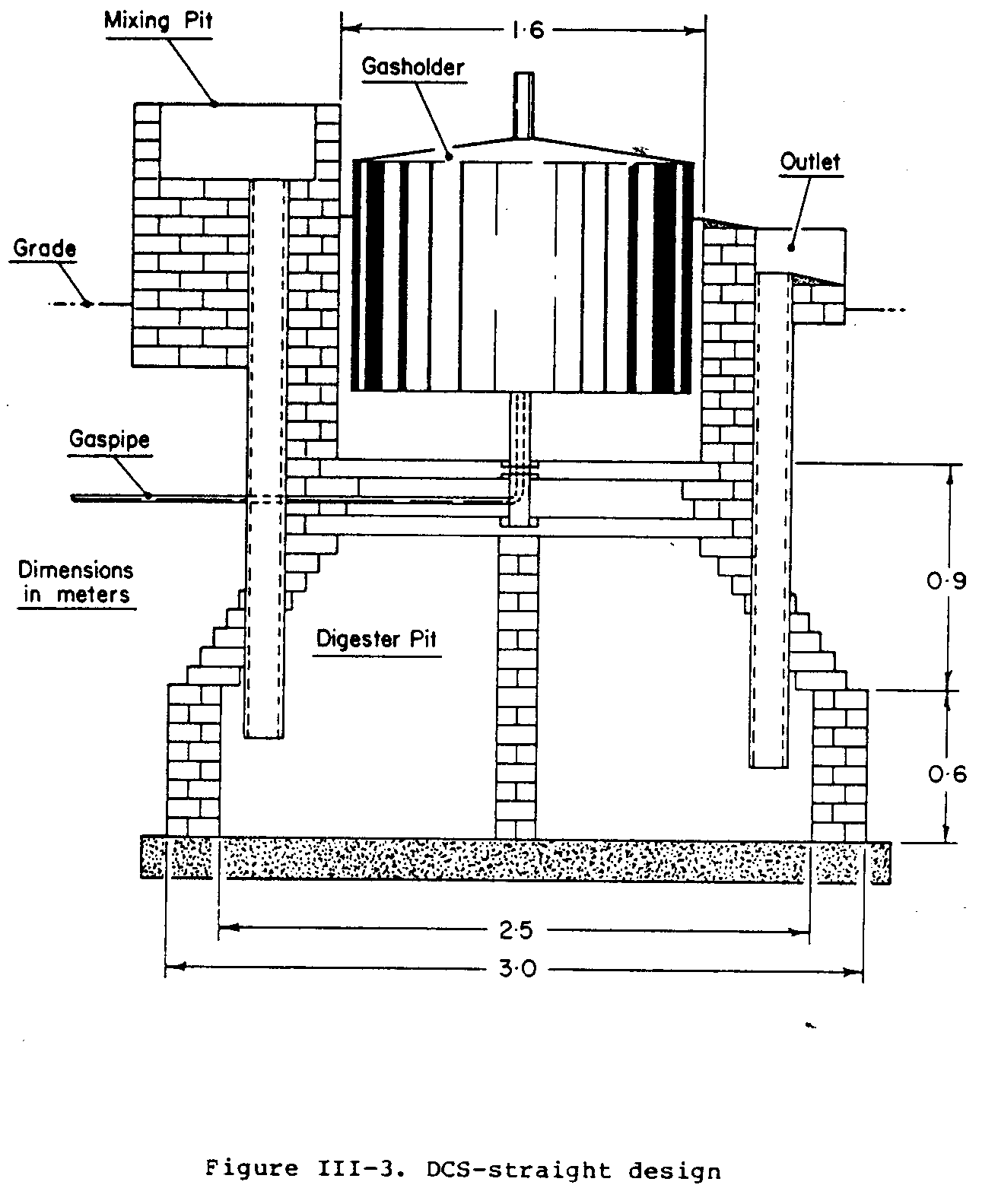

Most KVIC systems are designed to retain each daily charge for 50 days, although this has been reduced to 35 days in newer units. The slurry should be agitated slightly to prevent any chance of stratification. This is accomplished by daily rotation of the drum about its guide post for about 10 minutes. In Nepal, some gas holders have been painted to look like prayer wheels. They are turned during frequent religious ceremonies, or "puja" (individual prayer). The Nepali group, Development and Consulting Services (DCS), Butwal, also has modified the KVIC gas pipe connection. It has attached an underground fixed pipe to the guidepost, feeding gas through the guidepipe rather than connnecting a flexible hose to the roof of the gas holder.

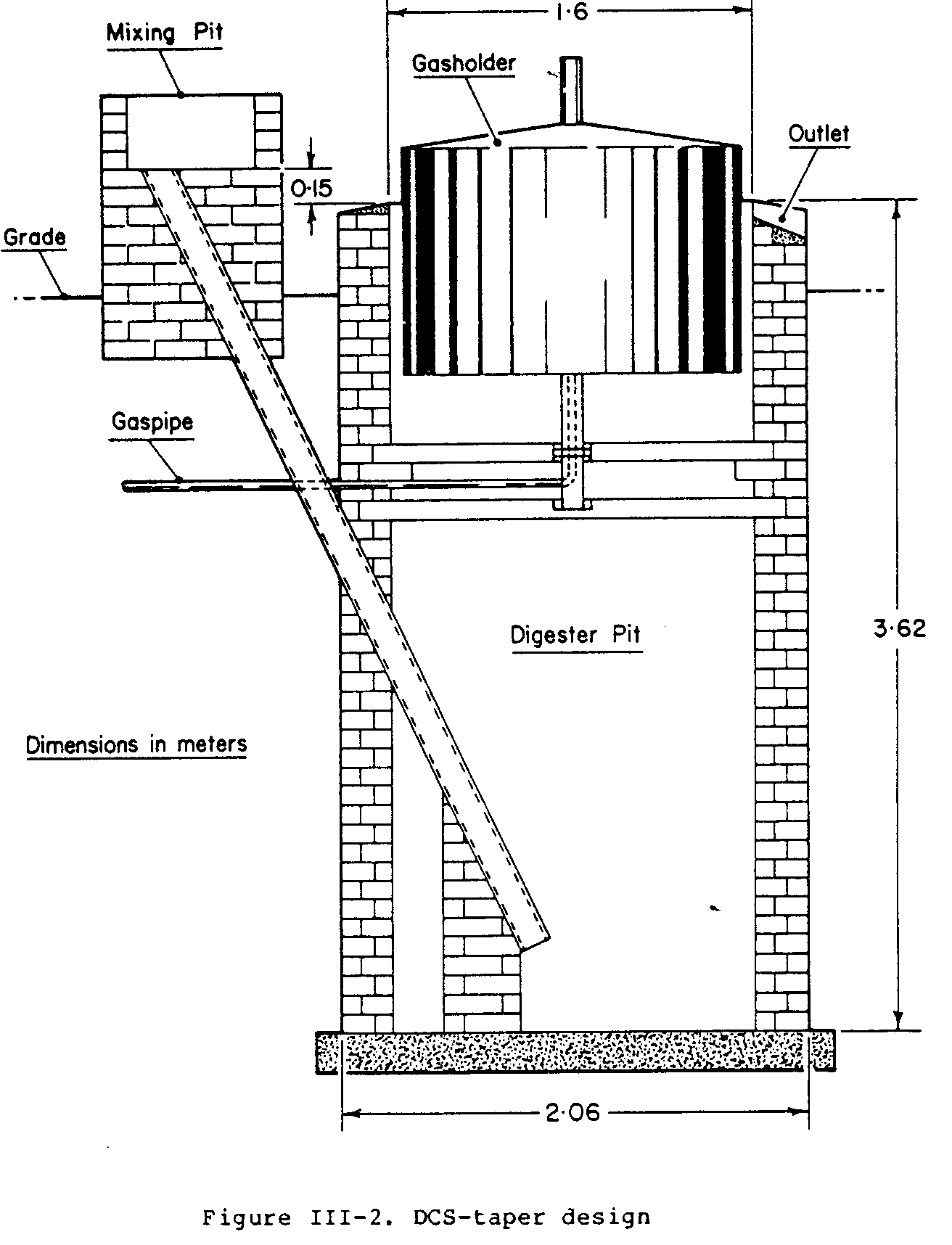

DCS uses a taper design for high water table areas (see Figure III-2) and a straight design for low water table areas (see Figure III-3).

KVIC systems are reliable if properly maintained, although drum corrosion has historically been a major problem. It appears that the quality of steel manufactured in India may have declined during the early 1960s. There are anecdotes of unpainted systems built before then that are still functioning. Drums should be coated once a year with a rustproof bitumin paint. Oil can also be introduced into the top of the digester slurry, effectively coating the steel drum as it rises and falls.

KVIC designs of over 100 [m.sup.3] have been constructed for institutions such as schools, dairies, and prisons. Though construction economies of scale exist for all digesters, the use of mild steel accounts for 40 percent of the system cost. KVIC systems are relatively expensive. The smallest family KVIC system costs well over Rs 4,000 (US$500) to install. KVIC has experimented with a number of materials, including plastics, for dome construction. The Structural Engineering Research Center, Rourkee, has done work with ferrocement, reducing costs somewhat. Ferrocement gas holders become extremely heavy as their scale increases, and they require proper curing and a fair amount of manufacturing skill. The curing process requires that domes be either submerged in water for 14 days or else wrapped in water-soaked cloth or jute sacks for 28 days. This raises questions about their use, or at least their fabrication, in many villages. KVIC would like to prefabricate both gas holders and digester sections at regional centers and then transport these out to villages. This would create rural industry and employment, and introduce quality control into the manufacturing process.

Dr. A.K.N. Reddy and his colleagues at the Cell for the Application of Science and Technology to Rural Areas (ASTRA), and the Indian Institute of Science, Bangalore, have modified the KVIC design in several important ways. The result is a shallower, broader digester than the KVIC design. Table III-1 shows some statistical comparisons between the two designs.(38)

ASTRA also examined the retention time for a charge of biomass, given Bangalore climatic conditions, and reduced the 50-day retention period suggested by KVIC to 35 days. It observed that since almost 80 percent of the total amount of gas produced was generated within the shorter time, the increase in digester capacity necessary to more completely digest slurry did not seem justified. Further research on cutting down retention time as a way to reduce system costs may suggest other design modifications. The shorter the retention period, the less digester volume (and hence, lower cost of construction) is required for the storage of the same volume of organic material. As shown in Table III-I, the ASTRA unit, though almost 40 percent cheaper than the KVIC unit, had a 14 percent increase in gas yield. Its improved performance needs to be monitored over time.(39)

Table III-1 Comparison of KVIC and ASTRA designs for similar Biogas Plants(40)

KVIC ASTRA

Rated daily gas output 5.66 5.66 Gas holder diameter (m) 1.83 2.44 Gas holder height (m) 1.22 0.61 Gas holder volume ([m.sup.3]) 3.21 2.85 Digester diameter (m) 1.98 2.59 Digester depth (m) 4.88 2.44 Digester depth-diameter ratio 2.46 0.94 Digester volume ([m.sup.3]) 15.02 12.85 Capital cost of plant (Rs) 8,100.00 4,765.00 Relative costs 100.00 58.80 Daily loading (kg fresh dung) 150.00 150.00 Mean temperature (Celsius) 27.60 27.60 Daily gas yield ([m.sup.3]/day) 4.28 [+ or -] 0.47 4.39[+ or -] 0.60 Actual capacity/rated capacity 75.6% 86.4% Gas yield (cm/g fresh dung) 28.5 [+ or -] 3.2 32.7 [+ or -] 4.0 Improvement in gas yield +14.2%

The ASTRA group conducted a series of tests on existing biogas systems and found that there was uniform slurry temperature and density throughout the digester,(41) and that the heat lost in biogas systems occurs mainly through the gas holder roof. It also found that when the colder-temperature water was mixed with dung to make slurry, the charge shocked the indigenous bacteria and retarded gas production. The result was a 40 percent or more reduction in gas yield.(42)

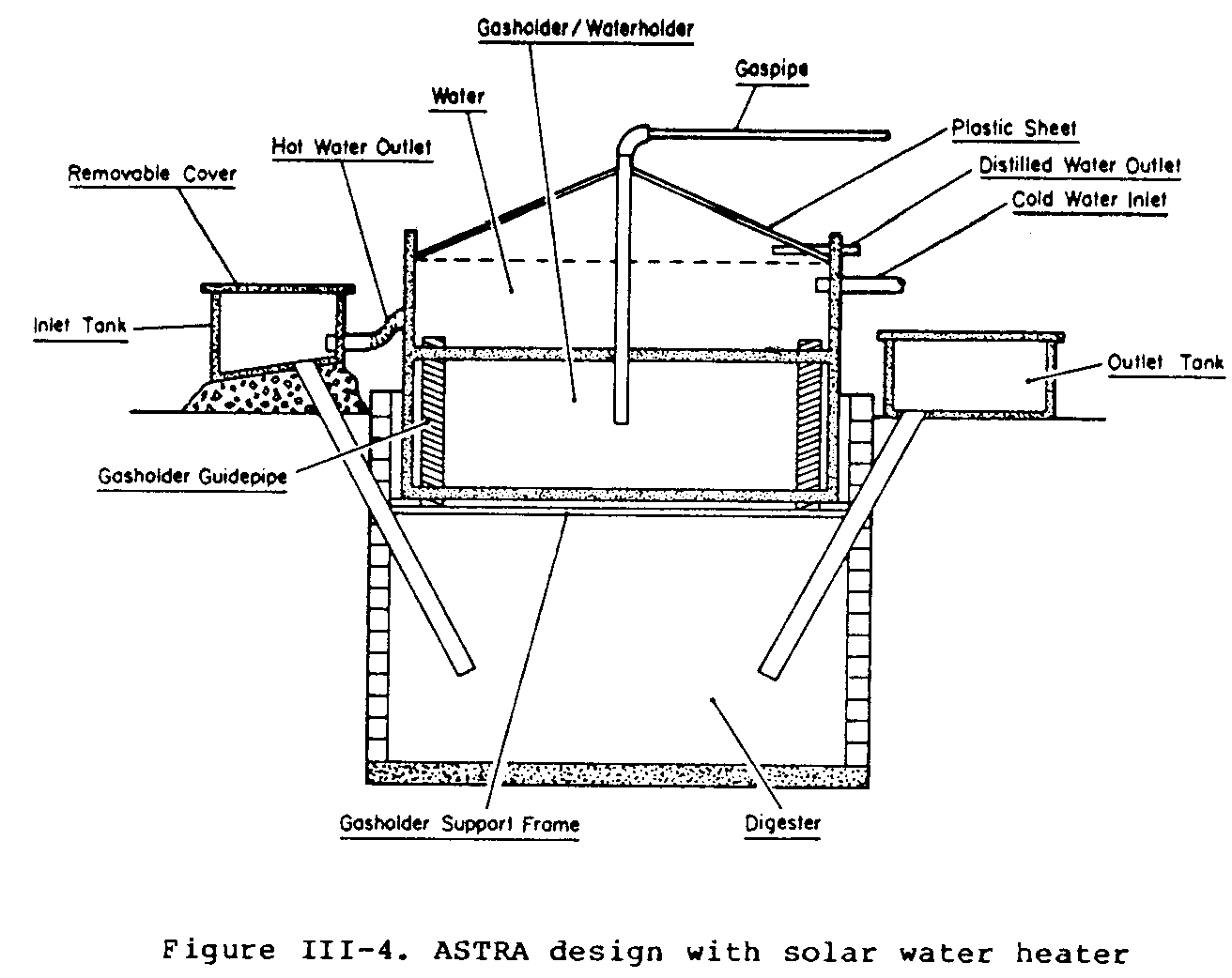

An important goal thus was to control the temperature of the slurry. This raised a number of problems: maintaining the slurry temperature at the 35 [degrees] C (95 [degrees] F) optimum; heating the daily charge to minimize temperature loss due to colder ambient temperatures; and providing insulation for the floating drum gas holder. ASTRA found an ingenious solution to all these needs. It installed a transparent tent-like solar collector on top of an ASTRA floating drum gas holder (see Figure III-4).(43)

This was done by modifying the drum design so that its side walls extended up beyond the holder roof, forming a container in which to place water. This water was drawn from the collector, heated by the sun, and mixed with the daily charge of dung. Preliminary data from the 1979 Bangalore rainy season showed an increase in gas yield of about 11 percent with this solar heating system. During this often cloudy period, the temperature of the water in the collector was only 45 [degrees] C (112 [degrees] F) compared with the 60 [degrees] C (140 [degrees] F) temperature recorded during the summer months. More work is needed to improve the cost and performance of this solar heating method, but its potential for reducing system costs seems promising, especially on a village scale. In addition, distilled water can be obtained by collecting the condensate as it runs down the inclined collector roof. The ASTRA group is constructing a 42.5 [m.sup.3] biogas system in Pura village, Tumkur District, near Bangalore, that eventually will incorporate ferrocement gas holders and solar heating systems, enabling the group to evaluate its ideas in an actual village context. Dr. C. Gupta, Director of the TATA Energy Research Center, Pondicherry, is constructing an ASTRA design biogas system with a community latrine in Ladakh, Jammu and Kashmir State, where the 3,600-meter altitude and chilly winter temperatures will provide valuable data on the performance of this design. Most recently, ASTRA has reportedly constructed a 2.3 [m.sup.3] fixed dome plant for Rs 900 (US$112). It may be possible to reduce this cost further by experimenting with a compacted earth pit that would be covered by a brick dome. The costs of constructing the brick digester would thereby be eliminated. Such experiments are still quite recent and the data on performance and durability are not yet available. Parts of Karnataka have large, brick-producing activities, and the easy availability of inexpensive bricks may account partially for this low cost. Nevertheless, the potential exists for large reductions in system costs, which could alter dramatically the economics of biogas systems.

The Planning Research and Action Division (PRAD) of the State Planning Institute, Lucknow, has been conducting biogas research at its Gobar Gas Experimental Station, Ajitmal (near Etawah), Uttar Pradesh, for more than 20 years. PRAD constructed the 80 [m.sup.3] community system in the village of Fateh Singh-Ka-Purva, which will be discussed later in this study. After several years of experimentation with designs modified from the fixed dome systems popular in the People's Republic of China, PRAD developed the "Janata" fixed-dome plant.(44)

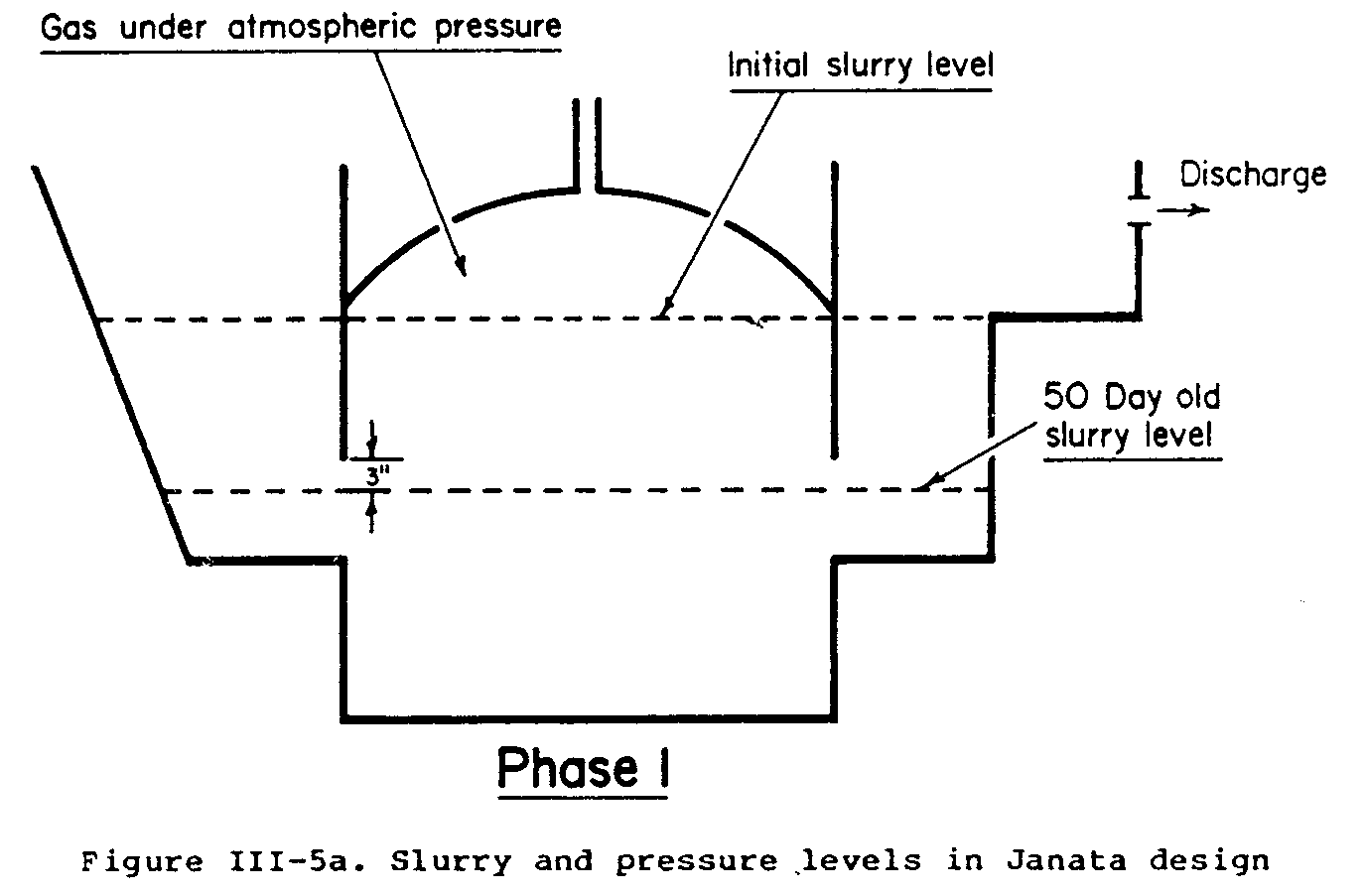

The PRAD design has several advantages. A Janata plant system can be built for about two-thirds the cost of a KVIC system of similar capacity, depending on local conditions, prices, and the availability of construction materials. The magnitude of savings due to the all-brick Janata design may diminish with increased capacity, but there is little data regarding large fixed-dome plants. One of the key features of the Janata and other fixed-dome designs is that inlet and outlet tank volumes are calculated to ensure minimum and maximum gas pressures due to the volumes displaced by the changing volumes of both gas and slurry inside the system.

Janata designs are relatively easy to construct and maintain because they have no moving parts and because corrosion is not a problem. One drawback is that Janata plants may require periodic cleaning due to scum build-up. As gas pressure increases in a fixed volume, the pressure pushes some of the slurry out of the digester and back into both the inlet and outlet tanks, causing the slurry level in each tank to rise. As gas is consumed, the slurry level in the tanks drops and slurry flows

back into the digester itself (See Figures III-5a through III-5d). Such movement probably acts as helpful agitation, but the motion may also cause heavier material to settle on the bottom of the digester. The result then is that only the supernatant flows through the system. Such buildup has been reported occasionally, and may result in a gradual accumulation of sludge that could cause clogging.

The more serious problem is posed by the heterogeneous nature of even the most well-mixed influent. Lighter material can form a layer of scum that remains unbroken precisely because the plants are designed to prevent the slurry level from descending below the top of the inlet and outlet tank openings in the digester, which might allow gas to escape through the tanks. This problem of scum build-up may be more serious in large-scale plants, and may require the installation of stirring devices.

The digester must be cleaned if build-up does occur. Someone must descend into the unit through the outlet tank and scrape out the sludge. The Janata plant has no sealed manhole cover in the dome. This differs from Chinese plants, for which sludge removal is assumed to be a regular part of normal operation. With the Janata plant, extreme caution must be used when entering the digester since concentrated [CH.sub.4] is highly toxic and potentially explosive. The Chinese often test this by lowering a caged bird or small animal into an emptied digester, exposing it to the gases for some time, and then descending only if the animal lives.

More research is needed on the kinetics and fluid dynamics of fixed-dome plants. The ASTRA observation of homogeneous slurry density in the KVIC unit would seem to conflict with some field reports, although poor maintenance and lack of thorough mixing may account for such discrepancies.

An important advantage of Janata plants is that their required construction materials are usually available locally. Lime and mortar can substitute for concrete. Neither steel (which often is scarce) nor ferrocement are needed, which reduces dependence on often unreliable outside manufacturing firms and suppliers. The dome of the Janata plant does require a good deal of skilled masonry, including several layers of plastering, to ensure a leak-proof surface. Many early plants leaked badly. PRAD reports this is no longer a problem due to extensive construction experience and the fact than it has trained many local masons in Uttar Pradesh who can competently construct such units.

Although PRAD recommends constructing a raised platform to support the earthen mound that serves as the form for the construction of the brick dome, the Chinese build brick domes with little or no support scaffolding. It is difficult to learn this technique unless one visits a construction team in China. The few manuals that exist are inadequate in explaining the construction method, often omitting details such as the angle at which bricks should be laid to form the correct arc for the dome, or the number of rings required for bricks of unknown dimensions.

Using some PRAD diagrams and A Chinese Biogas Manual, translated by the Intermediate Technology Development Group (London, 1980), the author directed the construction of a modified 2 [m.sup.3] Janata plant to be used as an experimental digester at the Indian Institute of Technology, Madras. A free-standing dome was successfully constructed, but the process took three days and required vigilant monitoring of cracks that occasionally began to spread around different areas of the brick rings that formed the dome. The safety of masons working under the emerging dome was cause for some concern. The weight of the partially formed arc sections easily could have proven fatal if someone had been caught underneath a collapsing section. It also was difficult to set the bricks at a proper angle. The dome emerged somewhat misshapen, despite the use of a two-pole system in which one pole defined the vertical axis and the other, equal to the radius of a sphere formed by "extending" the dome, pivoted about a nail. By rotating the vertical pole 360 [degrees] and lining up each brick ring with the angle formed by pivoting the "radius" pole between 45 [degrees] and 135 [degrees] (off the horizontal), the correct dome arc, and hence each brick's proper angle, should have been readily apparent. However, due to the irregular surface of the bricks, the varying amounts of concrete applied to the bricks, and the reluctance of the masons, for whatever reason, to use the device frequently, the dome construction became a matter of educated guesswork.

Given the short time many of the Janata systems have been operating, the possibility still exists that micro-cracks may develop in the dome over several years. The Center for Science for Villages, Wardha, has covered the top of its fixed-dome plants with water so that any leaks will be visible as bubbles. This idea could be further modified to incorporate an ASTRA type solar collector to produce warm water for hot charging. However, one of the additional advantages of the fixed-dome designs is that they are largely underground. This frees the surface land area for alternative use. Improved system performance due to solar heating must be evaluated against other possible uses of the land.

Fixed-dome plants release stored gas at pressures as high as 90 cm (36") of water column. As gas is consumed, and in spite of the changing slurry level, pressures do drop. The amount of gas inside the dome at any time can be estimated crudely by measuring changes in the slurry level in the inlet and outlet tank (as long as the daily charge has settled in the digester).

There is some concern that flame temperatures drop with lower pressures, increasing cooking time and gas consumption. However, there seems to be little complaint from individual users on this point. Minimizing gas consumption during cooking can be of great importance in a village system that requires gas for uses other than cooking. There are few data on the economic and thermodynamic efficiencies of diesel or petrol engines or of generators powered by a fixed-dome system. Presumably, more diesel would be consumed as pressure drops. Gas pressure regulators have been discussed periodically as a way to alleviate this problem. Regulators can ensure that enough pressure is maintained throughout a distribution system, and that occasional high pressure will not blow out valves or pipe joints. Work is now under way in Sri Lanka near the University of Peredeniya, in Uttar Pradesh, and in Bihar on fixed-dome plants as large as 50 [m.sup.3]. Plants of this size have been reported in China, but little information is available to confirm this. It remains to be seen if cost reductions observed in small-scale, fixed-dome plants will be repeated or even improved with increased scale. Constructing large domes from bricks, or even from ferrocement, may prove difficult and/or expensive since their performance and durability remain a matter of speculation.

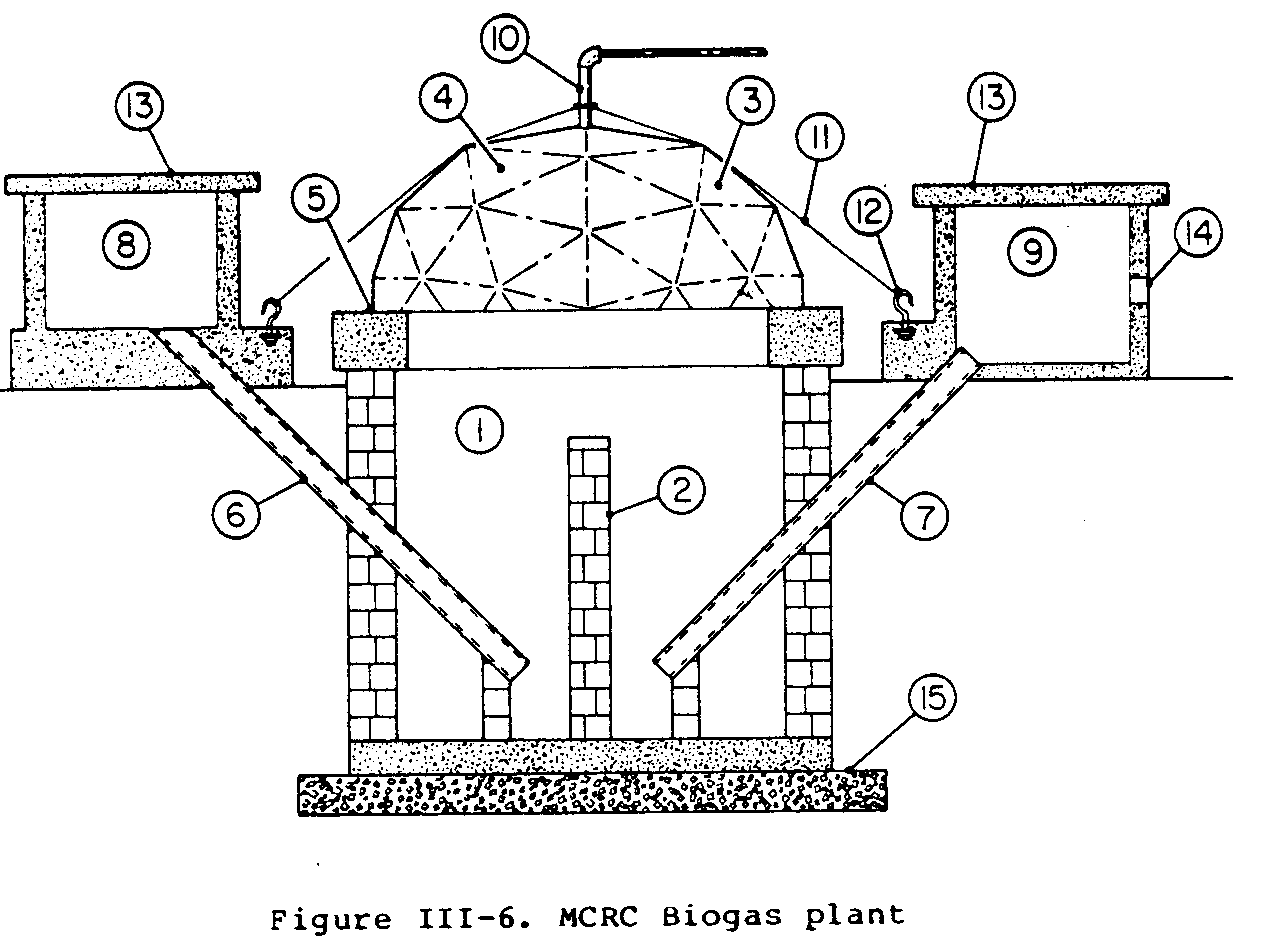

Variations on the fixed-dome design have been reported in Taiwan, where heavy gauge collapsible Hypalon/Neoprene bags have been used as digesters.(45) The Sri A.M.M. Murrugappa Chettiar Research Center (MCRC), Madras, has developed a brick digester with a high-density polyethelene gas holder supported

by a geodesic frame (see Figure III-6). The frame is bolted to the digester walls, and the plastic gas holder is retained by a water seal. The MCRC plant is still being tested in several Tamil villages and few performance data are available. The plant is less expensive than the PRAD Janata design and has the advantage of being easily and quickly installed. However, major questions remain concerning this design's durability and safety. Only small-scale systems have been constructed, although larger systems are planned.(46)

Development and Consulting Services (DCS) of the Butwal Technical Institute, Butwal, Nepal, has begun field testing a horizontal plug-flow digester design based on the work of Dr. William Jewell of Cornell University (USA). A long, shallow, horizontal system night require less water, be less susceptible to scum formation and clogging, and foster greater gas production. A plug-flow system should be easier to clean, and would require less excavation, helping to reduce costs. This system has great promise; a prototype should be developed within a year.(47)

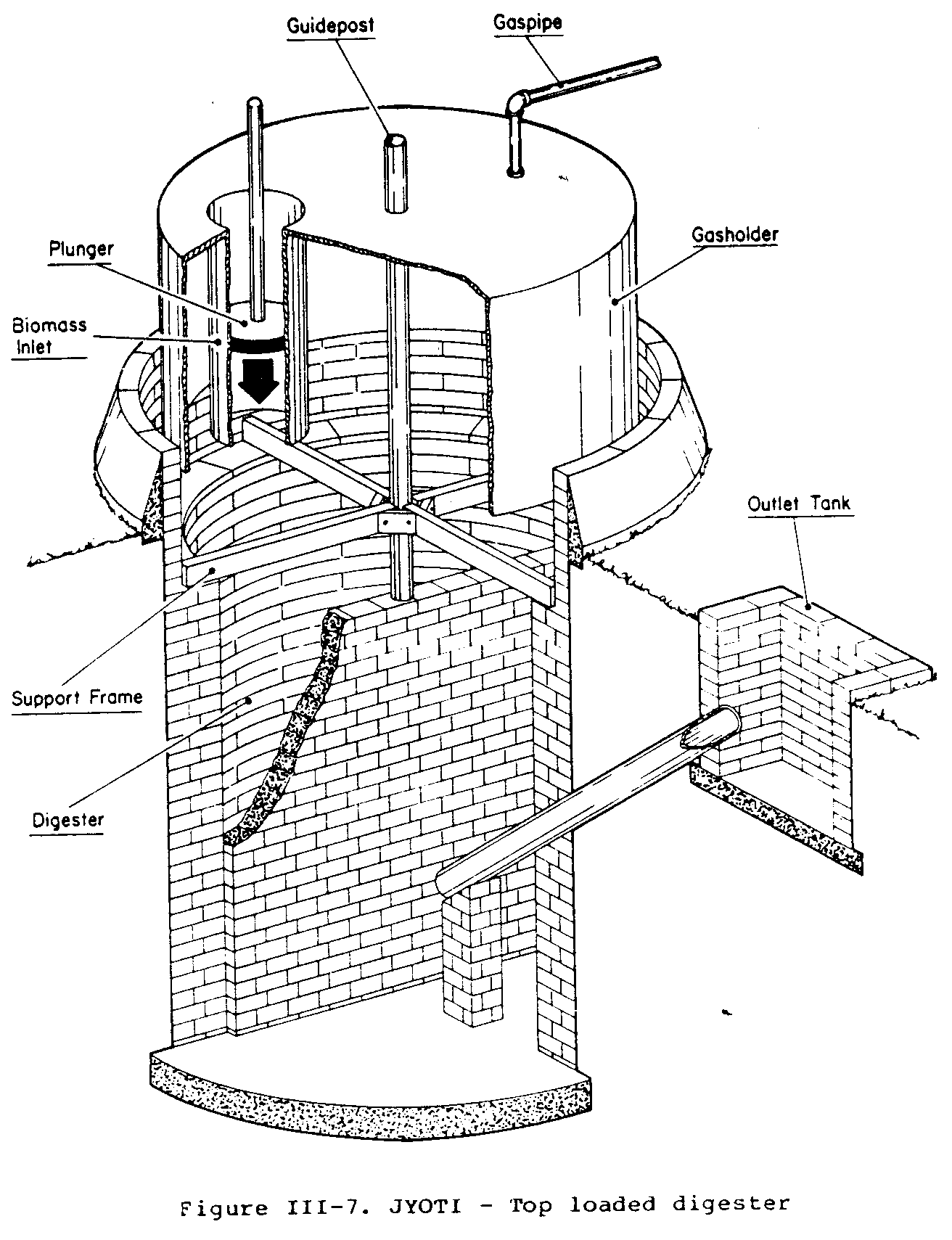

The Jyoti Solar Energy Institute, Vallabh Vidynagar, Gujarat (near Anand), has done some interesting design work in conjunction with the research on agricultural residues discussed earlier. JSEI researchers found that a scum layer was forming in experimental digesters that were fed with banana stems, water hyacinth, and eucalyptus leaves. This layer gradually reduced gas production to almost zero. The researchers concluded that the scum layer formed because the fresh biomass contained a good deal of oxygen between its cell walls. Since the shredded sections were lighter than the water they displaced, the biomass tended to float to the surface of the slurry. During experimental batch feeding, this scum layer was observed to sink gradually to the digester floor as digestion progressed. The scum layer that has troubled many of the digesters used for agricultural residues seems to form when fresh biomass, entering at the bottom of the digester, pushes up against heavier, older biomass that is settling toward the digester floor. The lighter biomass causes the heavier layer to rise, creating the thick scum layer. JSEI engineers devised an ingenious system of loading fresh biomass through the top of the gas holder to the surface of the slurry by means of a plunger arrangement (see Figure III-7).

This ensures that the heavier, partially digested material settles to the digester floor unimpeded by the lighter biomass. The JSEI innovation could be an important breakthrough in the use of agricultural and forest residues in biogas systems. In addition to solving the problem of scum build-up, the JSEI technique also seems to eliminate the necessity of excessive shredding or drying of residues, making the handling of these materials far less cumbersome and time-consuming. Biomass is merely chopped into 2-3 cm (.75-1.25") squares and then is pushed into the digester through a cylindrical tube inserted into the floating gas holder. The tube is always in contact with the slurry, even with the dome at maximum height, so that no gas can escape.

There remain a number of questions concerning the relative performance of fixed-dome plants versus floating drum plants. Conflicting data have been reported concerning equipment life, material durability, gas production, delivered gas pressure, and installation and maintenance costs. The Department of Science and Technology has established five regional testing centers where different designs of similar capacity are being monitored under symmetrical, controlled conditions in different agro-climatic regions. One such station visited by the author, in Gandhigram, Tamil Nadu, appears to have insufficient resources to assess accurately the performance of the different biogas systems that have been constructed. More rigorous comparative research on fixed-dome plants is needed, especially after further design improvements, such as those done by ASTRA, are completed. The effects of agitation, digester wall protrusions, and partition walls to improve gas yield need to be analyzed in different digester designs. It is not yet clear if the cost advantages of fixed-dome digesters outweigh the performance advantages of floating-drum digesters. This may be a function of the uses of the gas in a particular village, which determines the relative importance of providing gas at a constant pressure and the effectiveness and cost of pressure regulators currently under development. More research is needed before any conclusions can be made.

There are numerous experimental digesters with modifications of the designs described in the preceeding discussion. MCRC is planning to link its biogas plants with other biotechnology projects, such as pisciculture, algae growth, and organic farming. The Indian Institute of Technology - Delhi Center for Rural Development and Appropriate Technology is developing a system that will grow algae in the supernatant of a fixed-dome system. It will recycle the algae to supplement the daily raw material charge. The system will provide fertilizer, gas, oxygenated water for irrigation, and animal nutrients such as single cell proteins for fodder.(48) The idea is to generate the maximum yield per unit of local resources. Integrated systems have a great deal of potential, although their often elegant simplicity requires a great deal of skilled operation and effective maintenance. IV. System Operation

The appropriate role of a biogas system in producing heat, light, refrigeration, and motive power can be determined after end-use energy requirements over time have been assessed carefully, including any anticipated demand from population growth. The system's capacity should be based on a careful analysis of costs, local climate and soil conditions, and the net availability of biomass. This latter consideration must account for competing uses of crop wastes and dung, animal diet, grazing habits, difficulty of biomass collection, and the availability of labor. Also, the probabilities of the survey data remaining constant over time must be assessed.

Many family-sized systems have been designed with insufficient capacity to produce gas when it is needed at different times during the day or year. In India's colder northern climates, the drop in gas production during winter often has been underestimated. Great care should be exercised in preparing plant feasibility studies so that different contingencies can be accommodated without disrupting the operation of the system. For example, farmers often sell cattle during droughts (if the cattle survive), and this obviously reduces dung availability. Baseline surveys of available biomass can be distorted if conducted during periods of exceptionally good harvests or failed monsoons.

It probably is wise to build two or more medium-size plants in a village rather than one large plant, even though the total cost may increase. If problems or maintenance force a temporary shutdown in one of the digesters, the entire system will not be disrupted. If small-scale, fixed-dome system costs call be reduced to around Rs 400-500 (US$50-62), which does not seem impossible, clusters of small systems might be a more cost-effective way to provide energy than one large system. Some of the complexities of planning village energy systems are discussed in the following section on the economic analysis of biogas systems.(49)

Biogas plants require certain care during their initial starting up or "charging." If a digester contains a partition wall, slurry must be added from both the inlet and outlet tanks to equalize pressure and prevent collapse of the wall. While not essential, introducing either composted manure or digested slurry as seed material to the digester will speed up the initial charging. There is some disagreement over how best to start up a plant. One suggestion is to fill the digester as rapidly as possible until the outlet tank begins to overflow,(50) ensuring that the seed material is twice the volume of the fresh biomass initially fed into the system. Another is to increase gradually over a three-week period the amount of biomass mass introduced daily to the system.(51) The inlet and outlet tanks are then covered and digestion begins.

This chapter presents certain points that are not usually covered in discussions about biogas systems. The author recommends John Finlay's Operation and Maintenance of Gobar Gas Plants[N] (1978) for a more complete description of how biogas systems operate.

The plant should begin producing gas within 7-20 days, depending on temperature, agitation, etc. This initial gas is largely [CO.sub.2] and should be released into the atmosphere; it will burn poorly, if at all. This step may have to be repeated. Within a month after charging, however, the system usually will have developed a kind of critical mass of bacteria that is stable enough to digest the daily biomass charge and produce gas.

Care should be taken to ensure that the biomass fed into the system is relatively free from sand, gravel, and coarse fibers. Many inlet tanks have a floor that slopes away from the opening through which material flows into the digester. The opening is blocked during slurry mixing and the slurry is allowed to settle for several minutes. The plug is then removed and, as the slurry drains into the digester, heavier sediments and foreign matter collect at the lower end of the sloped inlet tank floor. This material can be removed after the slurry has drained into the digester. Material should be mixed thoroughly. Shredders, screens, and mixing devices may be required for village scale systems that handle a large amount of different raw materials. These precautions are recommended to reduce the chances of the digester becoming clogged in either the inlet or outlet tanks, or of having a scum layer form in the digester itself. More research is needed to understand the sensitivity of biogas systems to variations in the biomass charge. Similarly, ideal rates of loading different materials at different temperatures need to be determined. Many of the guidelines for operating biogas systems are based on trial and error observation in the field. The systems work, but their efficiency could be increased and their costs reduced.

Systems should be built in a sunny area to take advantage of solar radiation. They should be at least 5-10 meters from a source of drinking water sources, especially if human wastes are used. This is particularly important with large-scale systems, which could represent concentrated sources of enteric (intestinal) pathogens if they leak. Adequate space should be provided for raw material and water-mixing as well as for slurry handling and storage. Land and water requirements are a critical and often underemphasized part of a biogas system.

Care must be taken to minimize water condensation in the gas lines (possibly by including water traps), isolate sparks and flames from the gas lines (by including flame traps), and prevent pipe freezing in winter. Provision must be made for frequent inspection and maintenance of the system (including pipelines). There also must be proper handling of the slurry to conserve nutrients and minimize contact with pathogens in both the influent and effluent.

If a biogas system is not performing as it should, the following trouble-shooting sequence is suggested.(52)

1. Check temperature of the influent mixture. Sudden cooling of the slurry in the digester can impede microbiological digestion. Temperature variations should be kept to a minimum.

2. Check loading rate of organic materials. Overloading will cause material to flow out of the digester before the slurry has been digested.

3. Check pH levels, which may drop below the 6.0-7.0 minimum. Add lime to increase the pH level, if necessary.

4. Check for toxic material in the influent, and alter the composition of materials - mixed in the slurry.

Whenever daily feeding procedures are altered, the change should be introduced gradually so that the microbial population has time to adjust to the new environment.

V. Gas Distribution and Use

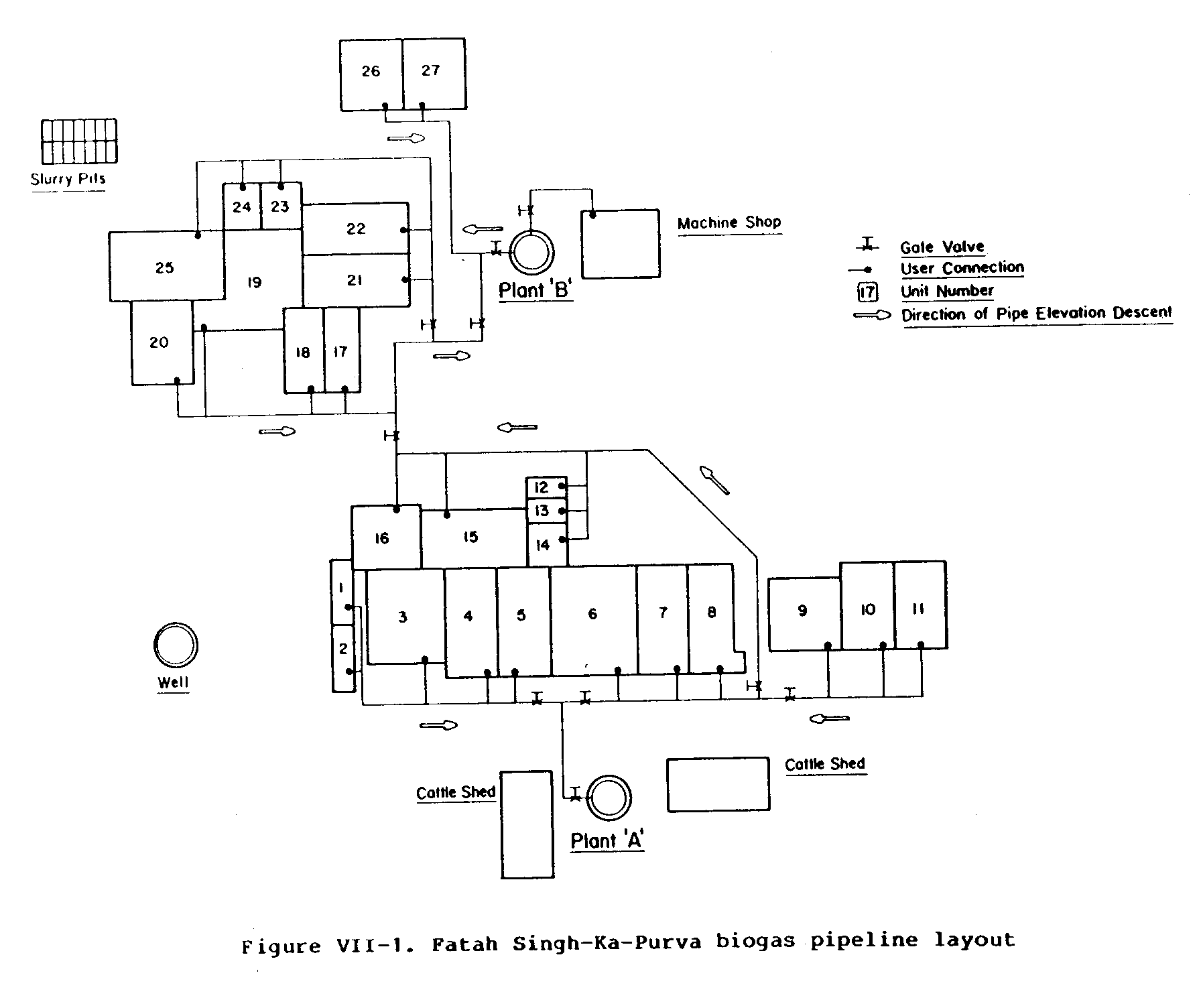

Gas distribution systems can cost from several hundred rupees for a family system to as much as three/fourths the total cost of a village scale digester (exclusive of pumpsets, engines, generators, etc.). Distribution costs can offset the scale economies of larger digesters. The distribution system in a particular village will be determined by local conditions, e.g., the distance between the points to which the gas must be distributed (houses, pumpsets, or industries), the availability of organic material, the difficulty of collection, and the availability and cost of construction materials.

Because the gas is usually released from a floating drum holder at a pressure of less than 20 cm of water column, the total length of the distribution pipeline is probably limited to less than 2 kilometers unless booster pumps are used, which increases costs. As delivery pressure decreases with pipeline distance, the flame velocity gradually becomes too low to support a stable flame. Similarly, pumpsets for biogas that are too far from the digester will require either an expensive pipeline, a gas storage vessel/bag of some sort, or possible conversion of the biogas to electricity.

Many different materials have been used in constructing pipelines, such as GI pipe and PVC or HDP plastics. It would seem possible to use clay or earthen pipe as well. Problems of gas leaks, durability, and rodent damage vary with material characteristics and care in construction. Generally, plastic pipes with a diameter greater than 35 mm seem best for cost optimization, ease of construction, and favorable friction characteristics to aid in gas flow.(53) The availability of large quantities of plastic piping may be a problem in certain locales.

One way to reduce the cost of pipelines might be to use the same pipeline for delivering drinking or irrigation water as well as gas.(54) Water condensation in the pipeline would have to be monitored carefully, as would any possible health hazards.

There are several descriptive accounts from China and Sri Lanka of using bags to store and transport gas to run pumpsets and tractors, and possibly to meet household cooking and lighting needs.(55) Kirloskar Oil Engines, Limited, is experimenting with a rayon-coated rubber bag that has enough capacity to power a 5 hp pumpset for two hours. It would cost approximately Rs 500 (US$40). The general problem with such bags is that they must be large enough to enable the gas to be released at the 10-12 cm water column pressure that is required for stove or engine use. Unless compressed in some way, a bag to provide enough gas for the daily cooking and gas requirements for a single family would have to be almost as big as the hut to which it was attached. In addition, the safety and durability of such a system are debatable, given the rigors of village use and the susceptability of such a system to vandalism. Despite the presence of [CO.sub.2] in biogas, puncturing a bag in the vicinity of a flame could cause a large fire. The danger is magnified if the gas is purified by bubbling it through time to increase its calorific value.

Nonetheless, a centralized delivery scheme where a few "regional" pipelines are laid near clusters of huts, and from which individual consumers fill their own storage bags, might have certain advantages. It may ultimately be cheaper than a full-scale pipeline system. It could expand easily if demand increased, and would free families from being restricted to using gas only during certain times of the day. Most community systems have several uses for gas and deliver gas only during fixed times of peak demand, especially during morning and evening cooking periods. This staggered delivery is designed to minimize gas waste, but can be inconvenient for villagers, who occasionally have to work during the time gas is delivered in their area.(56) A decentralized "gas bag" system might facilitate plant management and the easy monitoring of gas consumption. It might also allow for more efficient use of the gas. There are problems with this concept, but it has not yet received adequate attention from biogas system designers.

The costs of pressurized biogas cylinders, similar to Liquid Propane Gas (LPG), seem prohibitive. Biogas can only be liquified at -83 [degrees] C (-117 [degrees] F) and at a pressure of approximately 3.2 meters of water column. Reddy has estimated that such a gas cylinder system could almost double the cost of a pipeline in Pura village.(57) It is doubtful that individual families would have sufficient capital to purchase cylinders (Rs 300-700/cylinder). However, this concept should not be completely dismissed. The revenue-generating potential of a large-scale biomass system might justify an investment in a pressurized gas cylinder system. The compressor itself could be powered by the biogas system.

Using biogas for cooking is more complicated than the literature suggests. KVIC (1980), Finlay (1978), National Academy of Sciences (1977), Bhatia (1977), the Indian Council of Scientific and Industrial Research (1976), and Parikh and Parikh (1979) all suggest that gas requirements for cooking vary between 0.2 and 0.4 [m.sub.3]/person/day, although some anecdotal field reports suggest that these figures may be high.(58)

The difficulty in establishing norms for gas required for cooking is due to our scanty knowledge of rural cooking habits. The key to formulating cooking norms is to determine the usable or net energy used by a family to prepare meals. There are several levels of analysis needed to generalize about net available cooking energy. Diet varies regionally according to climate, custom, income, etc. Even the quality (calorific value) of identical fuel sources, such as firewood, varies regionally. Finally, the efficiencies of stoves (often a group of stones), and consequently the thermal efficiencies of different fuels, are also highly variable.

A detailed investigation of these variables would begin to shed some light on village cooking needs. These are more difficult to determine than the cooking needs of a wealthier farmer, who is the most likely consumer of a family-sized biogas plant, and on whom data do exist. At the moment, there is no accurate way to generalize about the gas required for village cooking. KVIC did attempt to generate data on the calorific value, thermal efficiency, and "effective heat" of different fuels,(59) but no description of its methodology is included in its report. It also assigned calorific values of biogas and wood, which conflict with other analyses, thus leaving KVIC information open to question.

Gas requirements for cooking can affect significantly the performance and economic viability of a village system, depending on competing uses for the gas. This is especially true if non-cooking uses of biogas are a source of revenue. More research and development are needed on cooking burners, stoves, and cooking vessels (and on their heat conducting properties), which collectively affect the efficiency of gas consumption. The relative system efficiencies of metal and terracotta cookware need to be analyzed. Though metal is a better conductor of heat, it also cools faster. Terracotta vessels take longer to heat yet they retain their heat. Rice cooked in terracotta vessels often is cooked only until half-done. The vessel is then removed from the fire, and the remainder of the cooking is done with the heat that radiates from the walls of the terracotta vessel. This is why both energy consumption and cooking costs need to be analyzed with respect to cooking systems, i.e., the fabrication of all utensils, their collective thermal properties, the costs of the various components (energy source, stove, vessel) over their useful lives, and the nature of the foods or liquids being heated.