VITA

Published By VOLUNTEERS IN TECHNICAL ASSISTANCE 1600 Wilson Boulevard, Suite 500, Arlington, Virginia 22209 USA Telephone: (703) 276-1800, Fax: (703) 243-1865 Telex: 440192 VITAUI, Cable: VITAINC Internet: vita@gmuvax.gmu.edu, Bitnet: vita@gmuvax

Understanding Paper Recycling ISBN: 0-86619-270-0 [C]1986, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Marjorie Bowens-Wheatley as editor, Suzanne Brooks handling typesetting and layout, and Margaret Crouch as project manager.

The VITA Volunteers who wrote and reviewed this paper have many years of experience in the paper industry. Jon Vogler, author of Work from Waste, specializes in small-scale industries, particularly those based on recycled materials. Peter Sarjeant, dedicated to keeping alive the processes of the old master papermaker's craft, is the author of Hand Papermakinq Manual. I. B. "Bruce" Sanborn is associate director of research and development at Consolidated Papers, Inc.; Phil Barr is fiber logistics manager for the Weyerhaeuser Company; and Dr. Bob Brooks, also of Weyerhaeuser, is the manager of pulp and paper educational activities. William Burger, retired mechanical engineer from Kimberly-Clark Corporation, assisted in the design of equipment for a micro paper factory in Tanzania.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Papyrus, from which the word paper is derived, is known to have been in use as early as 3000 B.C. Developed in the Nile Valley, it was made of strips cut from the papyrus plant stem, soaked, and laid, first lengthwise, then crosswise, to form a mat. The mat was then pounded and pressed into a thin sheet. Later, similar processes elsewhere used other fibers such as silk.

True papermaking, which began in China about A.D. 105, uses an entirely different process than the preparation of papyrus. It begins with rags, straw, bark, wood, or other fibrous materials that are chopped or cut fine. The fibers are pounded or pulped until they are separated from each other and mixed with water. Then the fibers are lifted from the water in a sieve-like screen that allows the water to drain away, leaving a thin mat of fibers. The fiber mat, which can be dried in place or removed and dried separately, becomes a sheet of paper.

The earliest recorded manufacture of paper is credited to one of the first "purchasing officers," Ts'ai Lun, head of the Imperial Supply Department of Emperor Ho of China. Ts'ai Lun experimented with a variety of materials: vegetable fibers, old hemp, cotton rags, old fishnets, and mulberry bark. The paper produced was cheap and durable and the surface was good--and, significantly, it was made of recycled materials.

Early European papers were also made from recycled linen or cotton rag. It was thick and rough, and the surface needed to be "sized" with gelatin or the ink soaked in. Ulman Stromer set up a mechanized papermill in Nuremberg, Germany, in 1390, using water-powered hammers for beating the material, a method already used by the Chinese. The craft accompanied the early settlers to America.

True mechanization was not achieved until 1799, when the Frenchman Nicholas Robert built a machine with an endless wire mesh and a pair of squeeze rolls. The device was taken to England and marketed by two stationers, the Fourdrinier brothers. In 1804, Brian Donkin, a millwright-engineer, built the first successful papermaking machine, in Two Waters Mill, Hertfordshire, England, and another in America in 1827. Crude early designs improved steadily. By the end of the nineteenth century, Fourdrinier technology was widespread; machines just over 2 meters wide supplied 25 metric tons per day to the growing market for newsprint.

Modern machines form paper in a continuous ribbon or web, not a single sheet at a time as did the ancients. A good papermaker in the olden days could make enough sheets in a day to weigh about 90kg. Today, an average machine makes 90,000kg per day! Much of the paper produced ultimately ends up as waste paper, mountains of it in some areas, which can often be recycled into other papers and paper products. The recycling of waste paper is the focus of this paper.

II. MODERN PAPERMAKING

FIBERS AND PULPS

Fibers are the fine, thread-like wisps from which paper, textiles, and many other materials are made. Tear a piece of paper and the fibers can be seen at the torn edge (more clearly with a magnifying glass). Paper fibers are made of cellulose, the basic building material of plants and trees. These materials can be made into paper by pulping (breaking them down until the fibers are loose and free of the substances that bind them), then reforming them while wet and finally drying.

Softwood (or coniferous) pulps are used for tough wrapping and packaging papers because of their long fibers; deciduous or hardwood pulps provide fine fibers for printing and writing papers.

To understand the waste paper industry it is important to know about the major types of primary wood pulp used in papermaking: mechanical pulp, and chemical pulps, which include kraft pulp, and sulphite pulp. Pulp made of recyled paper is known as secondary pulp.

Mechanical Pulp

Mechanical pulps yield the most paper per ton of wood, but are the weakest. They are made by pounding or grinding cellulose fiber, such as wood or sugar cane bagasse. One of the commonest uses of mechanical pulps is in the manufacture of newsprint. Newsprint is relatively weak and loses its strength altogether if wetted--a characteristic of mechanical pulp. It is used for rapid newspaper printing because printing ink is soaked up and dries very quickly, but it lacks the permanence of paper made from kraft or sulphite pulp. Strong chemical pulp is often added to mechanical pulp to give newsprint better strength. Mechanical Pulp often contains tiny particles of wood that have not been reduced to fiber and are visible to the naked eye, so paper made from it is described as "woody."

Chemical Pulps

A stronger paper product is most cheaply made by pulping cellulose fibers in such a way that they are not weakened by mechanical damage. The wood or stalks are first reduced mechanically to small chips, then cooked at high pressure with chemicals that attack the bonds between the fibers. The chemicals most commonly used are:

- Caustic soda and sodium sulfate, which produce coarse, very strong papers known as kraft, suitable for paper sacks and boxes that hold heavy weights.

- Various sulfides (such as ammonium and calcium), which produce finer fibers, suitable for making high quality, strong (but expensive) printing and writing papers (usually bleached white).

Secondary Pulp

Secondary or recycled pulp is made by vigorously agitating wastepaper in water (usually in a hydro-pulper, a tank containing rotating blades) to separate the fibers bonded during the original papermaking process. As these bonds are weaker than those of the original cellulose plant, hydro-pulping is a more gentle process than primary wood pulping and consumes less energy. Even so, each time paper is recycled it becomes weaker. Secondary Pulp is therefore never as strong as the primary fiber from which it was made. It can be almost as good, provided pure waste paper of the same type is used. For example, pulp made by hydro-pulping clean kraft sacks will make new sacks of only slightly lower quality, particularly if mixed with a proportion of primary kraft Pulp. If, however, the secondary pulp is made from material that contains newspapers or quantities of dirt, dust, or clay, it w.11 not be strong enough to make sack paper.

Coated Papers. In some cases the matted, absorbent surface of a paper is coated with a material that makes it glossy and smooth. This coated paper is better for printing. Coated papers are frequently used in magazines that are financed by the advertisements printed. In the process of hydro-pulping coated wastepaper, the coating is washed out; thus, the weight of fiber obtained from a ton of coated paper is less, often by 20 percent, than that obtained from a ton of uncoated paper. As a result, the value of scrap coated paper to the paper mill, and its selling price, will be lower.

If the coating is plastic or other material that will not disperse in water, the waste paper will require specialized machinery to recycle it and may reduce the value of more pure paper with which it is mixed. The same is true of polyethylene film, cellophane, glued paper, string, and any material that will not break down in water. Some of the various coated papers can be kept warm and wet in storage, then cooked in a hot caustic solution in order to biodegrade and break down the coating to release the fibers. Again, these papers require special machinery and handling to recycle and they may not be as valuable as simpler, plain papers.

Printed and Colored Papers. Both printing and tinting reduce the value of papers to be recycled. They make the pulp and the paper made from it dull grey in color unless bleached, which is expensive, or de-inked, which is also expensive. Tinting colors the pulp, which must then either be used for a limited range of similarly colored products (or cheap, grey products), or must be bleached. Therefore, white waste paper is more valuable than similar material that is colored. Unprinted waste paper is of a greater value than the same material printed.

STRUCTURE OF THE PAPERMAKING INDUSTRY

A review of the papermaking industry is needed to understand the ways in which waste paper is used. The manufacture and use of paper is one of the world's biggest industries; it takes place in:

- pulp mills, which process wood chips or other materials to make pulp;

- paper mills and board mills, which use pulp or waste paper to produce finished paper and board;

- paper converters, which use paper or board to produce boxes, tubes, rolls of tissue, boxes of blank office paper, stacks of printing paper cut to standard sizs, etc.;

- printers, who usually buy from converters, although larger firms such as newspaper presses may buy directly from the paper mills; and

5. "integrated" mills, which make pulp and then use it themselves to make paper.

These industries are huge, highly mechanized, and efficient. There are many of them, so they compete fiercely for the available markets. In countries where huge markets, skilled managers and technicians, and the massive capital needed for investment are available, handmade and small-scale paper manufactureres find it very hard to compete. Large or small, where these industries exist they represent potential markets for recycling waste paper--particularly in developing countries which may lack other resources for producing pulp.

III. WASTE PAPER COLLECTION

TYPES OF WASTE PAPER

Collecting waste paper is only difficult in a few poorer and more rural parts of the world. Elsewhere it is abundant. Selling it is often far more difficult, and only those who thoroughly understand stand the market are successful. The different types of wastepaper will therefore be considered in relation to their markets, starting with the most valuable, and going on to those of less value. Printing and Writing Papers

This category includes the best quality, most expensive papers that bring the highest waste paper prices. They are mainly made from bleached kraft and sulphite pulps. They are listed here in descending order of value.

Computer printouts. This is usually used to make high quality printing and writing papers.

Computer punched cards (tab cards). These may be buff-colored, the most valuable, or colored.

Printer trimmings. These are the edge trimmings left when a printer, boxmaker, or converter cuts the product to its final size. Their high value results from cleanness, lack of printing, and quality of the material. The value is increased if the printer has kept different grades separate. If not, it is usually worthwhile for the collector to sort the paper into different grades and separate the printed material from the unprinted. This labor-intensive activity needs no investment and can create many jobs. White trimmings should be sorted from colored, but different colors need not be separated. All may be sold to makers of printing and writing papers.

Office papers. Such papers as invoices, ledgers, letter papers, and record cards are included in this group. Printed or written on papers are separated from blank paper, and whites are separated from colors. Carbon paper and self-duplicating paper are also separated from the rest.

Grease proof and plastic-coated papers, file covers and bookbindings, metal file clips, string, and other office materials should be removed. For sales to a big mill it is unnecessary to remove staples or paper clips as the mill will remove these with magnets; smaller mills may reject them. Envelopes, including a few of the cheaper manilla variety (light brown), can be mixed in with whites, as can cream-colored envelopes and papers in any quantity. Adding machine rolls are usually good, white and unprinted. Office papers may be sold to makers of printing paper and high quality board.

School and letter papers. Letter papers may be of good quality, but school exercise books are low in value, although they often contain little ink (faint ruling does not count), because they are mostly of mechanical pulp. They can be sold to makers of printing and writing papers.

Pamphlets and magazines. Known in the trade as "pams," these are the lowest grade of (printing) papers other than newsprint. They are often coated and have heavy printing and large amounts of color. They are not worth sorting unless a paper mill has a Particular demand. They are heavy and it is easy to collect a great weight quickly. They are best sold to makers of low quality board.

Newspapers. In some countries, newspapers are little in demand due to their low strength. Telephone directories and some magazines are also made from newsprint. Their principal uses are as mixed waste paper for the manufacture of cheap flutings, grey board (cheap cardboard), or the middle layers of multilayer boards. There are three important exceptions:

- In poor countries where little is thrown away, even low quality raw materials are in short supply.

- Some countries that are heavily industrialized but lack their own sources of mechanical pulp, operate "de-inking plants." These remove ink from old newspapers by washing or bleaching. If such plants exist, or if it is economical to ship to countries that have them, prices for newspapers may be higher.

- Unprinted newsprint is discarded by the newspaper presses, as are trimmings from the sides of the paper and reel ends (the material at the center of the reel of newsprint, which cannot be used for technical reasons). The former can be sold back to manufacturers of newsprint and low quality writing paper. The latter is clean and large enough to be cut up and sold at a high price for food wrappings. Packaging Papers

Several types of packaging papers may be collected and recycled. Again, they are described here in descending order of their value.

Kraft Sacks. Kraft paper is recognized by its strength and brown color. It is used for large sacks, in two or three ply thicknesses, or for smaller bags and wrapping papers. Occasionally, whitish, bleached kraft is used. Watch out for sacks with polyethylene linings, often used to protect chemicals from damp, which are frequently reinforced with canvas or similar material. Tarred Papers (waterproof) are unmarketable and reduce the value of the load. Be sure sacks are empty.

An important decision is whether a greater profit can be made by selling kraft for re-use as sacks or to board or kraft paper mills for pulping. Re-use may entail repair or more sorting, transportation, and selling costs, but this usually pays off.

Corrugated Cardboard. This is a brown board made of three layers. The flat top and bottom layers are called liners and the corrugated (wavy) center is the fluting. The liners are often made of primary kraft, sometimes with secondary material (e.g., kraft sacks or old corrugated boxes) mixed in. The fluting is made from low quality material. Its function is to give stiffness to the wall of the finished box. Pulp for fluting manufacture may have a high proportion of mixed waste paper. Corrugated board is used to make packing boxes or cartons and these are in demand everywhere. Where there is no board mill, boxes can often be sold for re-use.

They are rarely contaminated with impurities, though some corrugated board and sack paper has been treated with an invisible resin, which gives it superior strength when wet. This material will cause problems for the paper mill, since it will be very hard to repulp. As a result, the value of this otherwise attractive waste paper will be lower.

Special Packaging and Wrapping Papers. These come last in the order of value because of the problems they cause with impurities, or contraries. Much modern packaging mixes plastics, metals, and other materials with paper and board, and it is difficult or uneconomical to separate them. Greaseproof, cellophane, and "wet strength" papers do not break down in water, cannot be pulped, and are difficult to recognize and remove. The main material is cardboard, containing a high proportion of cheap grey board (sometimes inside an outer layer of good quality). 'he amount of color printing is high too. Therefore, although such papers or boards are expensive to produce, their value as waste is no higher than that of mixed waste paper and may be lower due to contraries.

Mixed Waste Paper

Mixed waste paper is the lowest usable grade, and may have almost any composition. Grey board or multilayer board and similar packaging materials not acceptable in any other grade, as well as mixed, unsorted grades are satisfactory. A number of points are worth noting:

- This is the material often collected from municipal (town) garbage dumps by scavengers, or at specially built composting or refuse-sorting plants.

- In a district of offices, factories, or wealthy homes, mixed waste paper may contain valuable grades, worth sorting out for separate sale if labor costs are low or time is available. It is important to realize that the material left, after better grades have been removed, may bring a lower price. This leftover material is principally made up of newspapers, packaging, and cheap cardboard. However, if local mills make corrugated board, toilet tissues, and cheap grey board, then separated kraft sacks, brown paper, and old cartons can go to the first and printing and writing papers to the second. These can be sold for higher prices and will not reduce the price of the remainder for making grey board.

- Mixed waste paper can be an important source of material for recycling because, although merchants may have cornered supplies of high quality materials such as kraft, corrugated cartons, and printing and writing papers, quantities of mixed waste paper may still be obtained from municipal refuse by those who know what is valuable and what is not.

- Opportunities exist here for creating more jobs. Once the principles of sorting have been taught, the work requires neither capital, technical skill, nor bodily strength and may be undertaken by the disabled or mentally retarded.

- Mixed waste paper is worth half to a third of the value of old cartons, and this value is reduced if it is dirty, as is most material extracted from refuse dumps. By sorting out the higher grades and selling to the right market, a value equal to that of cartons may be achieved. The gain, however, has to be compared with the time and cost of sorting, selling, and transporting to several markets instead of only to one.

SOURCES OF WASTE PAPER

Waste paper can be collected from the following places, starting with that which is likely to be the most profitable:

Computer offices produce the most valuable of all.

Printing shops usually sell the trimmings themselves, or else they are collected by a merchant.

Newspaper presses almost always sell the edge trimmings and reel ends themselves.

Offices throw out quantities of blank paper as well as office records, letters, etc. If offices are small or located away from the city center, they may not have made arrangements to sell their waste.

Warehouses receive goods in sacks and corrugated boxes and often discard these after unpacking. Quantities may be large.

Factories may also have large quantities of packaginq that they do not want. These will get dirty on the factory floor unless rescued.

Shops receive goods in cartons; supermarkets and food stores often give or sell these to their customers. Small shops may not Produce enough to make a visit worthwhile unless there are other shops nearby.

Householders may sell their waste paper. It may be dirtied by food waste or ashes and may not be in large enough quantities to make a visit worthwhile. Still, thousands of people in many countries make a living by collecting household waste paper, sometimes paying the householder a small sum.

Refuse dumps receive only the paper that no one else has collected. Refuse collectors often keep saleable materials, but quantities of good quality waste paper continue to arrive at refuse dumps all over the world.

WASTEPAPER HANDLING

Transportation

Some method of transporting the collected material is essential. This may be:

- Sacks

- Handcarts

- Handcarts supported by a vehicle. When full, each cart is wheeled to the pick-up point, material is transferred to a vehicle, and the cart returns to collection. A good balance might be six carts to one vehicle.

- Horse-drawn carts. For the stop-go process of waste paper collection, this is not "old fashioned" but highly effective.

- Motor vehicle. Vans and trucks are a very expensive way of collecting any but the most valuable grades. With a wire mesh cage on top, to increase the load, they may be more economical.

- Trailers. These, also fitted with a cage top, make collecting even more profitable.

Cartons and boxes must be flattened before transport, by treading down or "baling."

Baling

Waste paper is baled to reduce the costs of transportation and storage. Baling involves squashing loose material into a densely- Packed, square-shaped bundle that is then strongly tied, in two or three directions, with wire or string.

Baling makes transport cheaper because a load of loose paper will overflow before it reaches the weight limit that the vehicle an carry. Baling makes storage cheaper because material, as well as being denser, can safely be stacked much higher.

Baling also reduces the risk of fire--a serious and ever-present risk in waste paper processing. Baling prevents air reaching the inside of the bundle, so flames only char the outside. However, baling does not totally remove the risk of fire, particularly if there is unbaled material lying around or if paper is wet, which causes it to ferment and the temperature to rise high enough for burning to begin.

Baling is most efficiently done in a press, a strong box equipped with some means of compressing the material and holding it while it is tied. In order of cost, this may be:

Treading Box: The simplest, cheapest baling press is a strong, hinged four-sided wooden frame with no top or bottom but a joint at one hinge. To operate, strong string is laid in the empty box, which is filled with paper, well trodden down. The string is tied, then the box joint opened to release the bale.

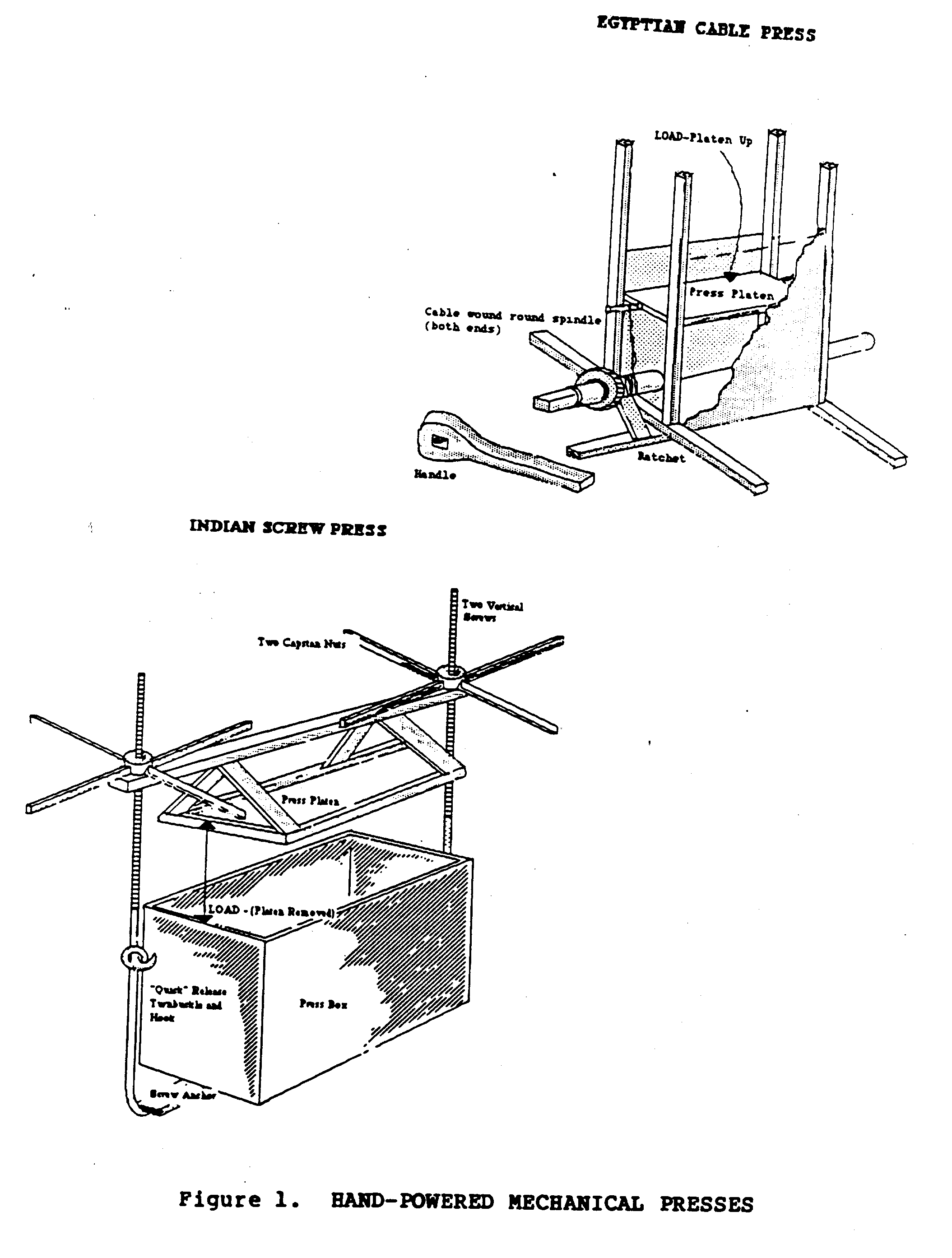

Hand-powered mechanical presses are used to obtain higher baling pressures. Some use levers; some use screws with capstan nuts (nuts fitted with long turning arms); and some use steel cables wound (with a handle) around a spindle bearing a ratchet (a device to keep the spindle from turning the wrong way). See Figure 1.

Motorized screw presses can be used where electric power is available. The press has a strong steel frame bearing an electric motor. The motor turns a vertical screw, which moves the "platen" (the strong, flat board that compresses the paper) up and down. Bales are so tight that thick wire must be used to bind them.

Hydraulic baling presses can be built to almost any size and power. They are expensive and need careful maintenance, especially in countries where there is desert sand or gritty soil nearby, but they are fast and very efficient. A wide range of automatic Controls and automatic wiring devices can be fitted onto the press.

MARKETS FOR WASTEPAPER

The markets for waste paper may be any of the following:

Merchants, who buy from printers, converters, and small collectors and sell at a profit to the mills;

Exporters, who buy from anyone, to sell on the world market;

Mills, full-size industrial paper or board mills;

Papermakers, small-scale operations (usually plants producing less than 30 tons per day); and

Small industries that make high-quality paper by hand, or that use paper to make other products.

In countries where large-scale paper mills do not operate, or where subtantial amounts of products are imported, there may be opportunities to set up small-scale or even handmade papermaking industries. These processes are described in the technical paper, "Understanding Small-scale Papermaking." Readers should be extremely cautious about any plans to compete with the economics of large-scale papermaking within any given country, as that paper makes clear. Other possible uses of waste paper--other than for repulping and paper production--are described below.

IV. ALTERNATIVE USES FOR WASTEPAPER

SHREDDED PAPER AS ANIMAL BEDDING

Banks, government agencies, and other organizations often shred waste paper into thin strips to prevent confidential information from being read. In England, this material is being marketed as bedding for animals. One commercial company, Shredabed Limited, markets both the material and the machinery for making it. They claim that:

- Pigs bedded on this material keep cleaner.

- Poultry gain a little more weight and suffer less mortality than birds bedded on wood shavings, straw, or sand.

- Other livestock suffer less from respiratory (breathing) problems when bedded on paper instead of straw.

- Shredded paper is much easier to remove from pens and stables after use. It spreads easily on fields and breaks down to form excellent manure.

- Shredded waste paper is easy to bale; as a result, the cost of transportation and storage is low.

In cities where livestock sell for high prices, but straw or other bedding materials are hard to obtain, this business may yield good profits, particularly if combined with an operation to sell the manure to gardeners.

EGG AND FRUIT BOXES FROM OLD CARTONS

A variety of strong, compartmented packing boxes can be produced from old, corrugated cartons with a small amount of hand-operated equipment (i.e., guillotine or paper shears, folder, punch for slotted tray pieces, and stapling machine).

The old cartons are cut down to accurate size, refolded, and stapled. It is important that the trays fit exactly and do not move during transportation. To make the trays, off-cuts from the boxes are guillotined to a standard size and punched.

FRUIT AND EGG CARTONS FROM WASTEPAPER PULP

Another process makes egg cartons from paper pulp using a small-scale paper plant called the Super Melbourne. Waste paper is first soaked, then pulped and refined. Pulping can be done in a domestic washing machine.

The equipment includes a refiner that reduces the pulp to basic fibers. The slurry that results is poured onto a sheet of mesh stretched over the forming tank of the Super Melbourne and a valve in the tank is opened. The water draining from the tank sucks moisture from the layer of pulp, which is then pulled from the tank on its sheet of mesh. The layer of pulp is folded over once and pressed between specially shaped dies, then it is laid to dry.

The process employs four people but labor costs are reduced when Super Melbourne machines are batched together for greater output. Output is 60 egg trays per hour, or 60 sheets of paper 84 x 66 cm. The machine requires only 300 watts of electrical power. Most of the water used is recycled. Floor space required is two square meters for the machinery and five square meters for drying.

More sophisticated machinery is availale for producing form 200 to 4,000 30-egg trays or equivalent products per hour Such a machine is made by Tomlinsons, but careful market research is essential before contemplating the heavy cost of a machine that tends to saturate any but the largest market.

BUILDING MATERIAL

All over the world the poor use waste paper to construct their homes. It is cheap, and will offer protection from wind and sun, but there the advantages end. It does not resist water, is highly flammable, and is eaten by rats. It is also weak, tears easily, and rots or becomes brittle after a short time. It is an unsuitable material that demonstrates the desperate condition of those who have no alternative. Asphalted paper, described below, is a great improvement.

ASPHALTED ROOFING SHEETS

Low-quality, low-cost roofing sheets with a life of about five years can be made from the very lowest grades of mixed waste paper, grades that would not be acceptable for papermaking due to the amount of dirt and contraries present. A factory with three molding machines costs about $200,000 for plant and machinery and can produce about 8,000 sheets daily, each about one square meter in area (over two million square meters annually). About 35 people are employed and 50 tons of paper per week are used. In India, the roofing material retails at around $0.25 per sheet; in South America, at about $0.60 per sheet. The manufacturing process consists of the following steps:

- The waste paper is washed and pulped in a hydropulper. A mechanical hammer mill or a Hollander beater may be used instead.

- The pulp is passed through a screen, to remove dirt, grit, or other impurities, and a board-forming machine to produce a continuous length of board that is cut to length as it comes off the machine.

- The board is spread on the ground and dried in the open air. The edges are trimmed on a rotating slitter.

- The board passes through an oven at the end of which are corrugating rollers. The corrugated sheets are then trimmed again and stacked in cradles.

- Next, they are dipped in a bath of hot asphalt. (Asphalt is flammable so the means of heating must be carefully chosen. The asphalt hardens rapidly at air temperature and the sheets are unloaded and stacked.

- When quite hard the sheets are either:

- taped in bundles for sale as third quality;

- sprinkled with mineral chips (while asphalt is soft) prior to packing as second quality; or

- hand painted and packed as first quality.

INSULATING MATERIAL

In Canada and the United States, there has been some experience using shredded waste paper as a thermal insulation material (a material that keeps warm houses warm and cool houses cool. The thermal efficiency (i.e., the effectiveness in preventing movement of heat) of the shredded and fluffed-up waste paper is almost as good as glass fiber. To guard against fire, the paper is soaked in a solution of borax or alum, or other fire retardant, and then dried. Such material is much cheaper than other thermal insulators and could be used widely where no straw is available, provided each batch is tested to ensure that the fire-retarding treatment is effective. It should be noted that rodents like the salty treated waste paper for bedding and penta-chlorphenol Phenol is sometimes used against them. This is carcinogenic, however, and very hazardous to use.

FUEL

It is possible to pulp waste paper, compress it into briquettes, sun-dry these, and burn them as fuel. However, these briquettes:

- produce sooty smoke, making them a poor choice for cooking or use in the home;

- burn poorly, unless made as very small sticks; and

- give out low heat.

Only in the absence of any conventional fuel are they likely to be regarded as acceptable for domestic use. Industrial users have tried "refuse-derived" fuel pellets made from municipal garbage but these have not proved satisfactory. Undoubtedly, there is a Potential here but research and development are needed.

BIBLIOGRAPHY/SUGGESTED READING LIST

Ainsworth, J.H. "Paper the 5th Wonder," Thomas Printing and Publishing Company, 1959.

Appropriate Industrial Technology for Paper Products and Small Pulp Mills. Vienna, Austria: United Nations Industrial Development Organization (UNIDO) , 1979.

Brook, S. "The Fine Art of Printing," Atlantic Monthly, April, 1974 (112-115) .

Becker, W.J. "The First Ten Years of the Fourdrinier," Paper Trade Journal, April 17, 1972 (34-41).

Becker, W.J. "The First 145 Years of the Paper Machine in the U.S.," Paper Trade Journal, May 27, 1972 (140-150).

Casey, James P. "Papermaking," Pulp and Paper, Vol. II, New York, New York: Interscience Publishers, Inc., 1960.

Goodwin, Rutherford "The William Parks Paper Mill at Williamsburg, Virginia", Lexington, Virginia: Bibliographical Society of America, 1939.

Hunter, Dard Papermaking Pilgrimage to Japan, Korea, and China, New York, 1936.

Hunter, Dard Papermaking, New York, New York: Alfred A. Knopf, 1967.

Hunter, Dard Papermaking in the Classroom, the Manual Arts Press Peoria, Illinois.

Hunter, Dard "Watermarking Handmade Papers," Scientific American, March 26, 1921.

Norris, F.H. Paper and Paper Making, New York, New York: Oxford University Press, 1951.

Sarjeant, Peter T. Hand Papermaking Manual. Covington, Virginia: Paper Make, 1976.

Small-scale Paper-making, ILO Technical Memorandum No. 8. Geneva, Switzerland: International Labour Office, 1985.

Sweetman, J. "Making Paper by Hand," Appropriate Technology, Vol. 3, No. 4. London: Intermediate Technoloqy Publications Ltd.

Thomas, C. The Paper Chain. London: Earth Resources Research Ltd., 1977.

Tsein, Tsuen-Hsuin "China, the Birthplace of Paper, Printing and Moveable Type," Pulp and Paper International Journal, February, 1974.

von Hagen, V.W. The Aztec and Maya Papermakers, New York, New York: Hacker Art Books, 1944.

Western, A.W. Small Scale Pulp and Paper Manufacture, London: Intermediate Technology Publications Ltd., 1979.

EQUIPMENT SUPPLIERS

Paper Mill Plant and Machinery Manufacturers Ltd. 181 S V Road Jogeshwari, Bombay 400060 India

Hindon Engineering Works Clubley, Bajoria Marg, Saharanpur 247001 UP India

Indo Berolina Industriea, Pvt. Ltd. I.B.I. House 5-86 Andheri Kurla Road Bombay 400059 India

Jessop and Co Ltd. 63 Netaji Subhas Road P.O. Box 108 Calcutta, India

SOURCES OF INFORMATION

Association of the Pulp and Paper Industry One Dunwoody Park Atlanta, Georgia 30341

Write for free four-page booklet, "How You Can Make Paper": American Paper Institute 260 Madison Avenue New York, NY