This article is from ECHO Asia Note # 32.

[Author Bio: Joining our team as a gap-year student in 2016-2017, Elliott was involved in various agricultural projects at our Chiang Mai office and seed bank sites. In addition to this experiment, Elliot contributed to our coffee seedling research experiment, an edible fern project, and expertly guided our social media accounts into the 21st century! We wish him all the best as he continues his B.S. studies at Nottingham University in the UK.

Editors’ Note: Biogasifier stoves can provide cleaner cooking and utilize low-quality feedstocks, while creating a value-added product (biochar) in the process. The experiment described in this article resulted from our questions about these stoves’ efficiency and about the effects of different feedstocks on cooking times, temperatures, and thermal efficiencies. We utilized the Novotera stove model from the NGO with the same name. ECHO Asia is getting more stainless steel models made here in Thailand to be used as templates; if you are interested in purchasing one, please let us know (echoasia@echonet.org) or look for them for sale at the 6th Biennial Agriculture and Community Development Conference happening here in Chiang Mai from October 3-6, 2017.]

Introduction

In many developing world households, meeting the daily energy needs required for cooking is burdensome and costly. Fortunately, low-cost cooking methods that require less fuel while burning more cleanly and efficiently are becoming available at the household level. One such method is the household gasifier cook-stove, designed to convert small amounts of carbon-based solid biomass (usually from waste or low-cost material) into combustible gases used for cooking (see Dr. Dussadee’s work for information on how gasifier stoves work (2013)).

Gasifier cook-stoves provide many advantages over cooking techniques in which traditional wood or other biomass is burned. The combustion of secondary gases (pyrolysis) in gasifier stoves allows for a cleaner and more efficient burn, reducing smoke that could otherwise lead to severe health problems (Berkelaar 2004). Since these stoves are designed to use small amounts of carbon-based biomass material, they can also greatly reduce the amounts of fuel needed for cooking. As a result, less time and energy are needed for gathering wood, and fewer trees need to be cut down, especially when low-quality or waste feedstocks can be used instead of wood. In some cases, these stoves can even help sequester carbon, rather than releasing it into the air—for example, when the spent fuel (a high-quality carbon-rich waste product created from the low-oxygen environment of the gasifier stove) is used as a biochar soil amendment (Hugill 2013).

Numerous gasifier stove designs and arrangements now exist. The basic TLUD (Top-Lit Up-Draft) gasifier stove design remains popular; these stoves are easy to light and quick to get started.

Using a relatively simple fan-powered updraft gasifier stove (Figures 1 & 2), staff at ECHO Asia designed an experiment to test the feasibility and practicality of using several different locally available, carbon-based, waste by-products as fuel. We tested rice hulls, coffee parchment, sawdust, and corn cobs, all of which are readily available agricultural by-products and are typically free in northern Thailand. We wanted to quantify the thermal efficiencies of the respective fuel types, temperatures at which they burned, and time of burning for each.

Materials & Methods

This experiment was conducted in October 2016 at the ECHO Asia Regional Impact Center in Chiang Mai, Thailand. On each of five separate occasions, four different locally available waste by-product materials (coffee parchment, sawdust, corn cobs, and rice hulls) were pyrolized using the same Novotera biochar cook-stove (Figure 1), a TLUD updraft gasifier design that utilizes a fan to force air up from the bottom (Figure 1).

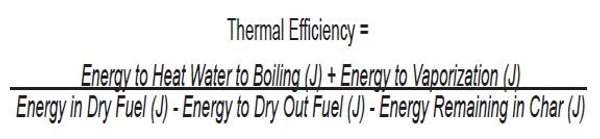

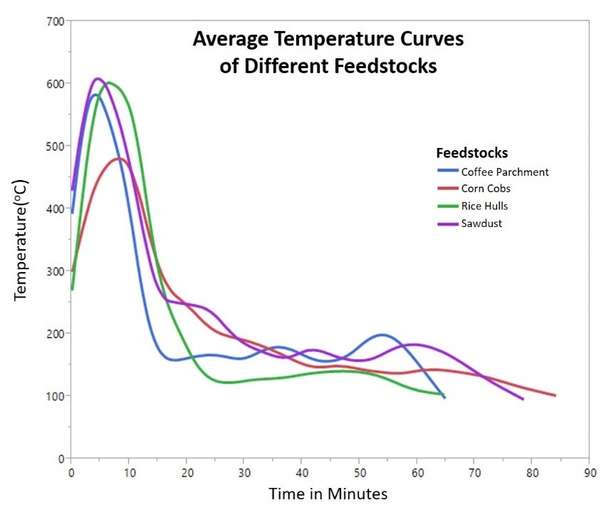

For each fuel type, we recorded the time it took to boil 1 L of water, total time of each burn, temperature of the burner from start to finish, and weight of the spent fuel at completion. We used this information to calculate the thermal efficiency of each feedstock when pyrolized in the gasifier stove, using the following equation:

We kept the initial fuel mass constant across fuel types at 600g per burn event. We deemed this number an appropriate amount of fuel based on the size of the gasifier stove and on previous experience. We used the following assumptions and information in our assessment of the recorded data:

We logged temperature data using an EasyLog Thermocouple and USB Datalogger that we placed between the flame and the stove-top on which the pot of water rested (Figure 1). We started recording time and temperature data once we deemed the fuel was burning on its own, usually within a few minutes of igniting one or two pieces of paper on the top of the fuel. We considered a burn event to be complete once the temperature dropped below 100 0C. We completed the entire experiment over the course of two weeks, avoiding any major changes in local climatic conditions and air temperatures.

We logged temperature data using an EasyLog Thermocouple and USB Datalogger that we placed between the flame and the stove-top on which the pot of water rested (Figure 1). We started recording time and temperature data once we deemed the fuel was burning on its own, usually within a few minutes of igniting one or two pieces of paper on the top of the fuel. We considered a burn event to be complete once the temperature dropped below 100 0C. We completed the entire experiment over the course of two weeks, avoiding any major changes in local climatic conditions and air temperatures.

Results

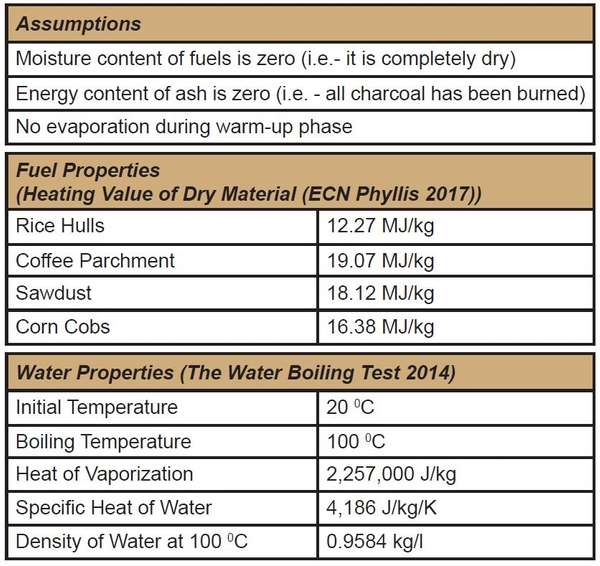

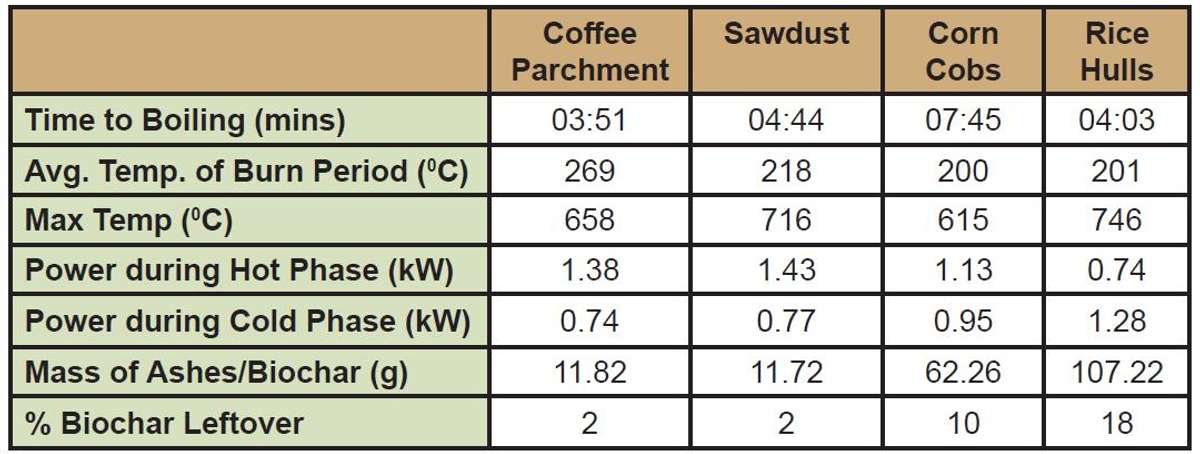

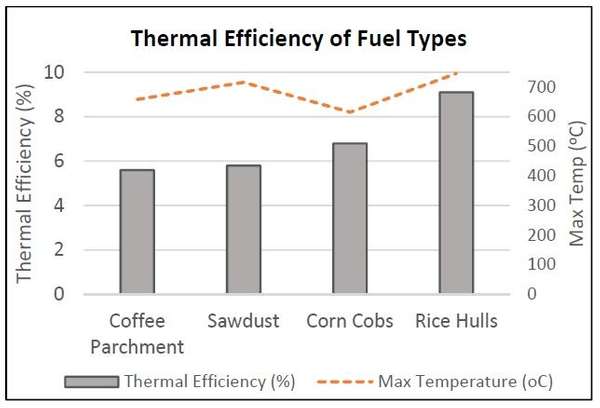

The results in Table 1 indicate that the gasifier model used in this experiment burned at high heat for a short period of time, with maximum temperatures reaching between 600 and 750 degrees Celsius across all fuel types. Once the fire was ignited, a liter of water came to a boil in less than eight minutes on average (Table 1). Combustion of secondary gases was observed in each of the burn events, indicated by the blue flame coming out of the secondary air holes, and the presence of a smokeless flame.

Rice hulls burned the hottest (Max Temp) (Table 1) and the fastest (Total Burn Time)(Figure 3), while corn cobs reached lowest maximum temperatures and burned the longest (Figure 3). Rice hulls had the highest thermal efficiency of the four fuel types in this experiment, at 9.1% efficiency (Figure 4). Rice hulls also produced significantly higher rates of biochar compared to the other fuel sources, which were reduced almost entirely to ash (Table 1).

A high value for thermal efficiency is desirable. Various gasifier stove models have claimed 30 to 50% thermal efficiency. Although thermal efficiency can vary based on factors such as fuel source, moisture content, and age of the material, our tests never achieved thermal efficiencies greater than 10%.

Conclusions

We would need to experiment further before we could optimize the thermal efficiency of this stove model and determine the optimal quantity or mass of each fuel type for the most efficient burn. However, we found that each of the tested fuel types can be used as an appropriate fuel source and will burn sufficiently well in this up-draft model. Coffee parchment, sawdust, corn cobs, and rice hulls are all locally available, inexpensive, and easily attainable in Southeast Asia. They were easy to ignite and burned quickly in gasifier cook-stove systems. Rice hulls appear to be an especially good fuel source; they burned more efficiently than the other fuel sources and created a higher biochar output, resulting in a secondary waste product that can be used to amend soils.

We noted some drawbacks of the Novotera biochar cook-stove: 1) the stove must be pre-loaded with fuel, making it difficult to add fuel during cooking; 2) temperature adjustment during cooking is challenging; and 3) this particular model uses an electrical mains electricity fan to force air in from the bottom. A fan with an adjustable speed would enable a user to increase or decrease airflow, which could overcome the temperature control issue to some degree. Likewise, powering the fan off a battery would allow for greater use in areas without mains power.

References

Berkelaar, D. 2004. Indoor air pollution from cooking fire smoke. ECHO Development Notes. 85:1-5. Available: https://www.echocommunity.org/en/resources/116af501-ac2e-4303-8c46-7a3d586a0818.

Dussadee, N. 2013. Household and farm level gasifier technology. ECHO Asia Alternative Energy and Appropriate Technology Symposium. Available: https://c.ymcdn.com/sites/echocommunity.site-ym.com/resource/collection/25f7955d-c19f-44ae-aa75-18a5dfc2b980/Household_and_Farm_Level_Gasifier_Technolog.pdf?hhSearchTerms=%22stove%22

ECN Phyllis Classification. 2017. Available: https://www.ecn.nl/phyllis2/Browse/Standard/ECN-Phyllis#sawdust

Hugill, B. 2013. Biochar - An organic house for soil microbes. ECHO Technical Notes 75:1-4. Available: https://www.echocommunity.org/en/resources/60196dbc-c62a-4bcf-a33f-251e7195d62c.

Kolmel, O., and D. Maxwell. 2017. Smokeless Novotera biochar cook-stoves. Available: https://www.facebook.com/pg/Novotera-442666302431979/about/?ref=page_internal

The Water Boiling Test: Cookstove Emissions and efficiency in a Controlled Laboratory Setting, 2014. 2.4.3. Available: http://cleancookstoves.org/technology-and-fuels/testing/protocols.html