Introduction

Need for Small Scale Systems

Many families in the tropics must assume a major role in production of their own foodstuffs. Incomes are so low that purchase of food competes with purchase of necessary items that cannot be hand-made. Most governments in the tropics do not have the resources to guarantee even minimum food to all of their citizens. Families in rural and urban situations often live in a minimum of space without soil that can be cultivated, or even a backyard in which a few animal cages can be placed. Such persons sorely need small scale systems that are in harmony with resources available.

Unfortunately, not enough study has been given to small-scale production systems. The small animals typically encountered on almost every small farm, chickens, ducks, geese, and rabbits, are still too large for many households. A small animal for a minimum sized system should produce food in units that can be eaten at one meal so that refrigeration is not necessary. Furthermore, such systems should use resources available to most families, including feeds that can be grown or purchased, cages that are home made, and systems of sanitation that protect the health of the animals and the residents of the household. The development of such systems has not attracted serious investigators.

The system described here, based on the Japanese quail, Coturnix japonica, is based on sound published information on this species and its requirements, and on three years of experimentation with quail at the household level. All apparatuses described were built and used, and actual costs and yields are reported.

Advantages and Disadvantages of the Quail

The quail has many advantages in comparison to any other small animal for home food production. The females begin to lay eggs at average of six weeks of age, and continue to produce eggs economically for at least a year. The extra males can be killed for meat at the age of 6 weeks. Even older animals are easy to butcher and can be prepared for food in a variety of ways. Birds need only a small amount of space. A cage permitting each bird 225 cm2 of floor space (44 birds per square meter) is the minimum requirement. The cage need not be more than 15 cm in height. Quail are efficient converters of feed. With each egg a female deposits an edible package of 8 percent of her own body weight (compared to 3 percent in the case of chickens).

On the other hand, quail have some disadvantages. The shrill crowing of the males can be disturbing. When males and females are mixed some males will peck at others so severely that they will blind them and eventually kill them. If not cleaned daily the cages can produce an odor. Quail are susceptible to some pests, parasites, and diseases that plague other poultry. Quail age more rapidly than other fowl and laying birds should be replaced each year. The chicks are quite small and tender, and easily destroyed by very small imperfections in their environment. They need to be protected in a brooder for 3 full weeks in the tropics. Once mature birds escape from cages they are difficult to recapture. During the short days of winter quail need supplementary lighting to keep them laying. A quail production system must take into account all of these points.

Advantages and Disadvantages of Other Small Animals

In contemplating a system of production of food based on quail, other animals should be considered as possibilities. We see the following advantages and disadvantages of other small animals:

Guinea pigs. They can be fed on grass alone, they are almost odorless and easy to manage, and the meat per animal is more nearly the size required for one dinner for a family. On the other hand, guinea pigs propagate themselves much slower than quail and, of course, they do not lay eggs.

Pigeons. They can be raised on rooftops on a minimum of food, for they scavenge for themselves, they produce young frequently, and require a minimum of attention. On the other hand, they do not lay eggs in usable quantities.

Chickens. They are versatile and very useful small animals, but require more space than do quail. They do not lay until 5 months or more of age.

Rabbits. They multiply rapidly and are easy to care for, but require more space than quail, and do not produce eggs.

Ducks. Some breeds are very productive and easy to care for, but require space. Ducks are very dirty when confined to small spaces.

Culture of Quail

Eggs: Their Care, Hatching

In order to produce fertile eggs, males and females should be enclosed with a maximum of two females per male. When several males and females are together, one male will dominate the others and will peck, injure, or even kill the other males. Nevertheless, the population approach is the easiest way to obtain fertile eggs. Since males prefer some females to others, some of the eggs will not be fertile. The optimum method for obtaining fertile eggs is to enclose one male and one female in a small cage. When male and females are enclosed together within 24 hours the newly laid eggs will be fertile. When males are removed from the cage, fertility will continue for up to 2 weeks (Woodward, et al., 1973). Eggs should be removed from the cage several times a day and stored without washing at a cool, but not cold, temperature (10-15°C) for up to one week. They need not be turned during this storage period.

Japanese quail in cages do not sit on and hatch their own eggs. Eggs can be incubated in any small household type incubator, including homemade models. They should hatch in 16 days. The ideal temperature for incubating is considered by Marsh (1971) to be 99.75°F (37.6°C). Woodward et al, (1973) give the following temperature and humidity schedule described for a forced air incubator:

|

Table 1. Temperature and humidity schedule. |

||||

|

Days |

Temperature |

Humidity (Wet Bulb Temperature) |

||

|

0 - 12 |

99.5° F |

37.5° C |

87° F |

30.6° C |

|

13 - 15 |

99.0° F |

37.2° C |

85° F |

29.5° C |

|

16 (10 Hours only) |

98.5° F |

37.0° C |

82° F |

27.8° C |

|

16 - 17 |

99.5° F |

37.6° C |

90° F |

32.3° C |

Household incubators vary in style and in evenness of temperature, etc. We have had satisfactory results with a small household forced air incubator, and also with a minimum sized inexpensive still air incubator. Only trial and error can resolve the question of exact proper temperature. If chicks hatch late, temperature was too low. If they hatch early and irregularly the temperature was too hot. Irregular hatching can also be caused by irregular temperature within the incubator.

It is very important to turn the eggs during incubation. Eggs are always placed in the incubator with small end down. They are rolled or turned up to 180° several times daily. Eggs need not be turned after the 14th day.

Care of Young Chicks

Before chicks are hatched, the floor of the incubator should be covered with a rough material (such as a flat piece of wire mesh with holes of no more than 0.5 cm). This surface permits the newly hatched birds to get their feet under them and to keep them there. If the floor is too smooth some of the birds will flatten themselves on the floor and never succeed in putting their legs under them. The dislocation is permanent. Such chicks and any other deformed chicks should be removed and killed.

Chicks should remain in the incubator until dry and fluffed out, several hours to 24 hours. They can then be placed in a home made brooder. As a brooder a cardboard box is the best that can be had, for it is new and sanitary. Some small holes are cut on one end for ventilation. A 50-75 watt light bulb is suspended 8-10 cm above the floor, toward one end of the box. The floor is covered with absorbent material such as newspaper, and a roughened surface such as wire screen.

At first, food can be scattered on the floor or placed on a shallow plate. A small amount of food is invariably wasted at this stage. Feeders offer opportunities for accidents and, if such opportunities exist, some chicks will be caught in corners or small places and will die. Feed used should be finely ground high protein starter feed for game birds (28-30% protein). If not available, commercial "chick starter", available almost everywhere, can be used, or a home made mix of half-and-half soybean and cornmeal. The box is covered with a wooden or cardboard top. The amount of heat that is appropriate can easily be determined. If there is not enough, the chicks will cluster or even pile themselves up near the bulb. When there is too much they will seek relief on the far corners of the box. The light should be maintained day and night. Where electricity is not available other constant heat sources should be improvised.

Chicks need water from the beginning, but watering containers pose a threat because chicks are easily caught and drowned. A small (no more than 1 liter) reversed jar watering container can be modified by filling the trough with clean marbles or pebbles to reduce the depth of the water. Such containers should be kept clean.

Once a brooder is established very little attention is necessary, except to replenish food and water twice daily. In a small box-type brooder no change of temperature is necessary because the chicks will seek the area where they are comfortable. A few chicks will probably die during the first few days of brooding. If deaths continue, Terramycin antibiotic can be added to the watering system for 3-5 days following manufacturer's instructions.

After 3 or 4 weeks the chicks can be moved to the brooder cage of the system described later. Their care will be essentially the same as that of adult birds, except that they will receive extra light for 2-4 weeks longer.

Chicks can be sexed by 6 weeks of age. The males have a breast much lighter and with less dark streaks than that of the females. When chicks are moved out of the brooder cage, extra males can be killed for eating

Care of Adult Birds

Adult birds are those of 6 weeks age or more. Details of the housing of adult birds and of simple feeding and watering containers are given later. Adult birds need no special care except to feed and water them twice daily. An appropriate protein level in the feed is 24-26 percent. In addition, some added crushed eggshells, coral sand or grits high in calcium are desirable for sustained egg production. Most diseases are treated with terramycin in the water. When terramycin is used, humans should not consume eggs for two weeks following treatment. Eggs roll to the front of the cage and are removed from the pens two or three times each day. Lights, as described later, are used from sunset until 10 o'clock at night, but no harm is done by longer exposures. Unless extra light is given, egg laying is reduced, especially during the short days of the tropical winter.

Arrangements for caging males and females are of great importance. For egg production, females can be placed together under fairly crowded conditions (up to 44 birds per square meter). For fertile egg production, housing arrangements have been described. It will always be necessary to maintain some males for multiplication purpose. Extra males can be kept together under crowded conditions until needed or butchered. The cage in which males are maintained for later use should be as ample as possible, with barriers and nooks for escape. Excess picking in small systems is best reduced by cutting off the tips of the beaks of the males using wire-cutting pliers. Cleaning the cages is an operation that must be done daily in the system described here. The cages are cleaned with a piece of sheet metal 4 x 16" (10.2 x 40.6 cm). The narrow edge of this is bent down to an angle of 90°, 0.25 inches (0.6 cm) from the edge. This forms a blunt instrument that can be placed in the space between hardware cloth floor and sheet metal subfloor, and can be used to push the droppings of the birds off the metal to the rear of the cage. A box can be placed below the metal floors to catch the droppings and hold them until discarded or transferred for use as fertilizer.

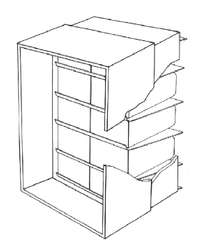

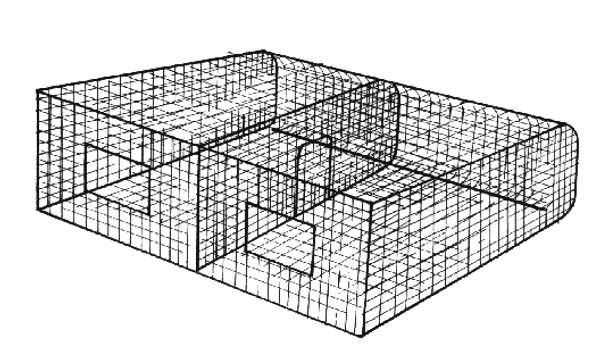

Figure 1. Caging system for 3' x 5' window space. Interior doors and strip for lighting have been removed. Wire mesh cage construction.

Construction of Cages

Window-Sized Frame and Doors

In discussing the cages designed for this system the dimensions of wood are given by their nominal dimensions in the United States, their true dimensions in the English system, and their true dimensions in the metric system.

The cage system was designed to fit into a window space of 3 x 5 feet (914.4 x 1524 cm). It consisted of a heavy frame, protective doors, 5 cages, sheet metal tops and false bottoms for the cages, feeding and watering devices, and an electrical lighting system. See Figure 1.

The heavy frame in which the cages were placed was constructed of 2 x 8 (1.5 x 7.5 inches, 3.8 x 19.0 cm) resinous pine planking. This was cut to two lengths of 35.875 inches (91.1 cm), and two of 57.875 inches (148.8 cm). The shorter pieces were rabbeted on one edge 0.5 inches (1.3 cm) deep to accommodate the longer ones, and the 4 pieces were fitted together to make a rectangular frame 35.875 x 71.875 x 7.5 inches (91.1 x 182.6 x 19.0 cm).

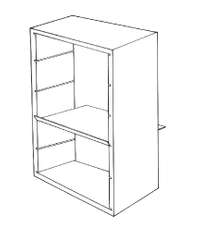

Figure 2. Heavy frame for cages showing scores for sheet metal subfloor; one such subfloor is in place. Completed frame exterior dimensions indicated.

Before nailing the frame, the sidepieces were scored deeply with a saw to accommodate sheet metal that became the roofs and subfloors of each cage. These cuts were 0.5 inches (1.3 cm) deep, and 0.125 inches (0.32 cm) wide. They were inclined toward the back of the cage. The edges of these cuts on the front of the side pieces were 1.0, 12.25, 23.50, 34.75, 46.00 and 57.25 inches (2.6, 31, 59.7, 88.3, 116.9 and 145.cm) from the upper edge, and 0.5 inches (1.3 cm) lower on the rear (Figure 5). The heavy support frame is designed to fit into the space for a 36 x 60-inch window (91.4 x 152.4 cm) and with 1.5 inches (3.8 cm) extending into the room. (Figure 2).

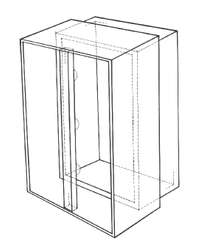

In front of the heavy frame supporting the cages an interior frame was constructed slightly larger than the support frame and nailed to the heavy support frame - measurements are not given here. This frame extends into the room, leaves a space between cages and doors so that light bulbs can be mounted, and provides a mount for the doors (Figure 3). The construction of this frame can be as simple or as elegant as desired. It is this frame and its doors that are seen within the house and that provide an airtight and odor-tight barrier between the animals and the interior of the house.

A plank of 1 x 4 (0.75 x 3.5 inches, 1.9 x 8.9 cm) was cut and fitted into the center front of the interior frame after cages were installed. This was used for mounting of the electrical system of 3 light bulbs and, in addition, divided the space for doors into two. The front edges of the frame and of the center board were lined with thick felt. Two solid plywood doors, each 0.75 x 18 x 61 inches (1.9 x 45.7 x 155 cm) were cut and hinged to the frame; then hasp and lock were attached so that the doors could be tightly shut.

The cage frame, the interior frame, the center board, and the doors were all painted before installing cages, and the electrical system was mounted.

Figure 3. Inner frame for mounting doors and lights. Electrical wiring is not shown.

Figure 5. Details of the door and lock mechanism. a. Side view, cage, b. lock mechanism before folding, c. folded lock mechanism.

Individual Cages

Figure 4. The individual cage showing divisions, screen, and openings for doors. The ends and center partitions (shaded) are constructed of wood.

Before mounting the cages, six galvanized flat sheet metal pieces were prepared 34.5 x 15 inches (87.6 x 38.1 cm) to be used as tops and subfloors. The sheet metal was folded downward along the long edge to an angle of 90°, 0.5 inches (1.3 cm) from the long edge, to give rigidity to the sheet. Squares 0.5 x 0.5 in (1.27 x 1.3 cm) were cut from the corners at the rear edge of the sheet, and the 6 sheets were then inserted into the grooves of the frame to provide 5 more or less equal divisions (Figure 1), with the folded edge toward the front and pointed upward.Cages were constructed of 0.5 inch mesh (1.3 cm) galvanized hardware cloth. From a roll of such cloth 36 inches (91.4 cm) wide, a piece 44 inches (112 cm) was cut, and trimmed along the edge to 32.5 inches (82.6 cm). This sheet was folded crosswise at 13, 21, and 34 inches (33.0, 53.3, and 86.4 cm) to form a trapezoid-shaped cage (Figure 4). The two edges of the cage were wired together. Three pieces of plywood (0.375 inches, 0.9 cm) thick were cut in the form of trapezoids, and in one of these an opening about 4 inches (10 cm) high and 1.5 inches (7 cm) wide was cut. The 2 pieces were mounted within the trapezoid cage at the sides, and the piece with the opening was mounted in the center. The hardware cloth was mounted to the wooden pieces with staples. Openings were cut on the right and left hand sides of the front side (10 x 32.5 inches, 25.4 x 82.5 cm) of the cage (Figure 4). These were 6 x 5 inches (15.24 x 12.7 cm) in length and width.

The cages were then mounted into the frame by removing the doors from their hinges, laying the frame on its side, carefully positioning the cage in the space, with front of the cage parallel to front of the frame, and were then fastened to the heavy frame with two large screws through the trapezoidal end pieces. When all the cages were fastened to the frame, the frame was carefully turned over and the cages were spaced and screwed to the other side of the frame.

The frame was then placed upright and was ready to mount in a 3 by 5 feet (914.4 x 1524 cm) window-sized opening. (Note: In practice, the authors used such frames and cages in a sheltered location out-of-doors and not in a window opening. They believe, however, that all design features here are realistic for the proposed purpose.)

Cage doors, watering and feeding systems

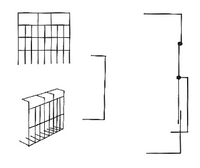

Steps in making a waterer or feeder from a soft drink can. See text for mounting instructions.

Sturdy cage doors are necessary to prevent loss of birds as well as entry of other animals. A simple door with locking device was designed that meets these requirements (Figure 5). The doors of 0.5 x 1-inch mesh (1.3 x 1.5 cm) heavy hardware cloth were cut 1 inch larger than the openings left for them, thus 6 x 7 inches (15.2 x 17.8 cm). These flat sheets were wired to the hardware cloth of the cage so that they opened inward (Figure 5a). The locking device was made from a 4 x 4 inches (10.2 x 10.2 cm piece of the same hardware cloth, cut (Figure 5b), and folded as shown (Figure 5c). This lock was wired to the door, but hung outside of the cage, and by its own weight maintained the door securely fastened when properly used. The closed position of the door and lock is shown in Figure 5a.

The watering and feeding devices were identical. They were made from aluminum soft drink cans with "pop" tops. These cans were 4.8 inches (12.2 cm) long and 2.7 inches (6.9 cm) in diameter. To remove the beverage two holes were cut on the sides with a household can opener. These holds were triangular in shape, and resulted in a smooth folded edge of metal near the ends of the can (Figure 6). A cut was made between the two openings, and the metal was folded inward to form a cylindrical trough. The entrance slot of this cylinder was 1 inch (2.5 cm) wide. Holes of the diameter of the can were cut in the hardware cloth at the front of the cages at floor level. The troughs were pushed halfway into these holes, and wired securely.

Food and water were added to the cages from outside, without the necessity of having to open the cage doors. When replenished twice daily, the food and water were always sufficient.

Electrical (Lighting) System

The electrical lighting system consisted of three sockets for bulbs mounted on the center board of the inner frame (Figure 3). The upper one faced the center or the uppermost cage front. The others faced the divisions of cages 2 and 3, and of 4 and 5, respectively. White incandescent bulbs were placed in these sockets. A wire led to an indoor double switch and plug-in socket. The switches were wired so that one controlled the light of the uppermost (brooder) cage, and the other the lights of the other 4 cages. Fifteen-watt bulbs were used for the purpose of giving extra light to the birds from darkness until 10 PM. When birds of 3-4 weeks of age were transferred to the cages, the upper cage was used as a brooder, and the upper socket was equipped with a 60-watt bulb. This was used day and night until the birds no longer clustered near it, or until the birds were 6 weeks old. The bulb was then replaced with a 15-watt bulb.

Alternative Systems of use of Cages

Each cage of the caging system can be used independently. Based on experience we recommend the following alternative uses for a cage:

- Use as laying cage for females more than 6 weeks of age; 8 females optimum, 12 maximum.

- Use as a cage to retain males for breeding purposes; 6 males optimum, 8 maximum.

- Use as a brooder cage for young birds from 3 to 6 weeks of age; 25 birds optimum, 30 birds maximum.

- Use as a population mating cage to produce fertile eggs; 1 male and 2 females optimum, 2 males and 6 females maximum.

- Use as a holding cage for birds to be eaten; males or females, optimum 12 birds, maximum 16.

In using the system on a continuous basis for an egg and meat production system we recommend the following:

- Obtain about 100 small birds and brood them in a cardboard box brooder. When they are 3-4 weeks old transfer them to the cages, and use 60-watt lights to keep them warm up until no more than six weeks of age. At six weeks of age divide them into males and females.

- Place all males in lower 2 cages and all females in upper cages. Butcher males as needed until only 6 remain in lowermost cage. Transfer some females to freed cage used by males. If problems occur due to crowding of females, butcher extra females.

- After 5 months place males and females in 2 or 3 cages at the maximum densities recommended. Collect and refrigerate eggs for incubating for two weeks. Return males to their cages. Incubate eggs in two batches so that no eggs have been stored in the refrigerator more than 1 week.

When the young are 3-4 weeks old, remove females from the upper cage and brood the young there for 2-3 weeks more. Then, replace the old birds of two cages with some new ones. Replace all males with young birds. Extra birds can be butchered or used to start other systems. Insofar as possible, maintain older birds together and younger birds together, so that when birds are rotated the older ones are replaced. At times it may be necessary to crowd the birds together during a transitional period. Although this is permissible, females stop laying when too crowded. New cycles should be begun about twice a year and as a minimum once a year.

Use of Quail for Food

Use of the Eggs

The eggs of quail are used in the same manner as those of chickens, except they are smaller. About 5 eggs weigh the same as one chicken egg. The shell is also somewhat thicker and harder to crack. The shells from fresh eggs can be cracked on the sharp edge of a frying pan or can be opened with a quick jab of a pointed knife. The shell tends to adhere to fresh boiled eggs. It is more easily removed after rolling the boiled egg to fragment the shell.

Because of their small size and attractive appearance quail eggs are often used for special purposes. They can be used whole, or sliced in salads and casseroles, or served boiled or whole with a sauce.

Pickled quail eggs are a specialty. They are made by placing the eggs in hot water and boiling them 5 minutes, with occasional stirring. The eggs are drained, rinsed, and placed in commercial white vinegar overnight. They are then washed, and remnants of the shell and membrane are removed by hand. The eggs are then packed loosely into jars, and the jars are filled with a solution of half vinegar, half water, with 75 g. salt per liter. Other flavoring ingredients are sometimes added. The pickling solution is usually boiled. After capping the bottles, the pickled eggs can be stored at room temperature.

Use of the Meat

In order to kill the quail, the bird is held in one hand with head extended on a wooden chopping block, and the head is severed with one blow of a heavy knife or cleaver. The bird is dropped into a can or box until muscular activity ceases. Then, with a scissors or knifepoint the loose skin of the breast is cut from neck to vent. The bird is then rapidly skinned, pulling the skin off over legs and wings. The feet and the tips of the wings are cut away with the skin at this time.

A knife is then inserted below the sternum, and the sternum is then split. The carcass is held open, and the abdomen is split to the vent area. Internal organs are then removed. The heart, liver, gizzard, and testes are conserved for eating. The entire process of butchering requires about 5 minutes. Our birds averaged 125 g. after cleaning. Quail meat is considered a delicacy. It can be fried or roasted, and many recipes have been developed. For maximum yield, cooking in stew or fricassee is recommended.

Econoimc Aspects

Cost of the Cage System

Costs of the cages will vary from place to place. The costs of one window-sized caging system are given below. These costs represent prices in Mayaguez, Puerto Rico, September 1978. A good cage should easily last for 5 years or more.

|

Table 2. Frame costs. |

||

|

Frame: |

Supporting Frame |

$8.00 |

|

|

Inner Frame and Center Board |

3.50 |

|

|

Sheet Metal Floors |

5.75 |

|

|

Doors |

9.00 |

|

|

Hinges and Other Hardware |

4.00 |

|

|

Electrical System |

5.50 |

|

|

Subtotal: |

33.75 |

|

Cages: |

Hardware Cloth |

8.50 |

|

|

Wire and Metal Doors |

1.00 |

|

|

Screws |

0.50 |

|

|

Subtotal |

10.00 |

|

|

TOTAL |

45.75 |

In addition to costs for the cage, the following costs were borne:

|

Table 3. Additional costs. |

|

|

Simple Incubator |

$23.50 |

|

Lamp for construction of brooder |

2.35 |

|

Water Container |

1.75 |

|

TOTAL |

$27.50 |

An analysis of the amount and cost of production over 7-1/2 months (6 weeks to produce adult birds, 6 months of production) follows. In this analysis it was assumed that 120 fertile eggs were produced for a second six months of production, and that all birds were butchered for meat at the age of 7-1/2 months.

|

Table 4. Production costs. |

||

|

Number of Birds: |

Eggs Incubated |

120 |

|

Chicks Hatched |

84 |

|

|

Crippled Chicks Eliminated |

12 |

|

|

Chicks that Died |

8 |

|

|

Adult Birds; 6 weeks |

64 |

|

|

Females at Beginning |

31 |

|

|

Females at End |

26 |

|

|

Average Females |

28.2 |

|

|

Males at Beginning |

33 |

|

|

Males Retained |

8 |

|

|

Males at the End |

7 |

|

|

Production: (kg) |

Males Sacrificed |

3.1 |

|

Eggs Produced |

72.3 |

|

|

Meat Available at 7.5 Months |

4.23 |

|

|

Total Production |

79.63 kg |

|

|

Feed Use (kg) |

First 6 Weeks |

34 |

|

By Laying Females |

230 |

|

|

By Males |

40 |

|

|

Total Feed Consumed |

304 kg |

|

|

Economics |

Feed Conversion rate |

3.85 |

|

Cost of Each Kg of egg or meat |

$1.02 |

|

The analysis shows that high quality eggs and meat can be produced at about $1.02 per kilogram. This analysis does not take into account, however, the costs of equipment, the electricity, or of the labor. We believe that once capital costs are met, and with family labor donated, the amount of food produced (0.44 kg. per day, about 125 g. protein) might be very attractive to a small family. If the family can produce some high quality feed, such as mixture of soybeans and corn, costs can be reduced to a small fraction of those quoted here.

Discussion

The eggs and meat production system explained in this publication is so small that it could fit into almost any home. It is a unique plan for use of a unique animal. The problem of appropriate diet for the birds is perhaps the first limiting factor in this production system. Producers are cautioned that quality of diet cannot be sacrificed. In this respect, high protein content is necessary for sustained performance. In addition, producers should avoid more than two generations of inbreeding by bringing in fresh stock (males, for example) periodically. It is well to emphasize again that incubation and breeding of chicks are techniques that must be done right, or the whole operation is likely to fail.

Literature Cited

Anon, Not dated. Quail Raising. LDC Pamphlet 01-78. Livestock Development Council, Manila, Philippines. 12 pp.

Marsh, A.F. Not dated. Quail Manual, 7th edition. Marsh Farms, Garden Grove, California. 52 pp.

Podems, Marc. 1975. Coturnix Quail Challenges the Chicken. Organic Gardening and Farming, June: 36-41.

Woodward, A.E., Abplanalp, H., Wilson, W.O., and Vohra P. 1973. Japanese Quail Husbandry in the Laboratory, Dept. of Avian Sciences, University of California, Davis. 22 pp.

Cite this article as:

Martin, F.W., A. Martin-Davis, and A. Maffioli 1998. Quail: An Egg & Meat Production System. ECHO Technical Note no. 35.