NOTE: Dr. Townsend sent the following to ECHO in answer to an inquiry about the African hive. It is re-typed to save on airmail costs, for distribution solely to those who have requested information on this hive. It should be used only for personal use without permission from Dr. Townsend.

Introduction

Several types of hives and their construction will be described but it must always be kept in mind that availability of materials is of extreme importance. There are places where lumber is readily available at reasonable prices and, certainly, if it is termite-proof or termite-proofed it is the best and easiest material to work with. However, there are other areas where timber is very short in supply or extremely expensive and other methods of hive construction must be considered although the same principles could be adapted as those described for lumber. As an example, Dr. N. Koeniger, working recently in Sri Lanka where lumber is very expensive, has persuaded some of the pottery makers to make a hive similar to the Kenya top bar hive out of clay which can be quite readily used with top bars. This was prompted by the fact that Apis cerana seems to be readily attracted to clay pots. Perhaps something similar could be derived for use with the African bee in timber-short areas. Peter Paterson has suggested the use of a skep-type clay or cement hive for the Sudan, with a hole in the top over which a super made in a similar manner can be placed for collection of honey. This would not have the advantages of the removable frames, but it certainly would have the advantage of producing a better quality honey, and could perhaps be made easier by the pottery people.

Hive Designs

The hive designs selected for development programs should keep a number of factors in mind. The hive should be cheap or almost free for the making, at least in the early stages of development so that the beekeeper can start off with no investment at all except his labor. As success is reached in the program, they can develop slowly into either the making or the purchase of more useful types. All the designs, however, must keep in mind that the beekeeper should be producing a good quality of honey, not contaminated with brood or pollen, and encourage beeswax production. The hive itself should be large enough to maintain the colony for honey production without encouraging swarming, yet be adaptable to the peculiar characteristics of the African bee. It also must be easy to manipulate with very few openings where bees must be smoked to keep them under control while the colony is being operated.

The hive designs selected for development programs should keep a number of factors in mind. The hive should be cheap or almost free for the making, at least in the early stages of development so that the beekeeper can start off with no investment at all except his labor. As success is reached in the program, they can develop slowly into either the making or the purchase of more useful types. All the designs, however, must keep in mind that the beekeeper should be producing a good quality of honey, not contaminated with brood or pollen, and encourage beeswax production. The hive itself should be large enough to maintain the colony for honey production without encouraging swarming, yet be adaptable to the peculiar characteristics of the African bee. It also must be easy to manipulate with very few openings where bees must be smoked to keep them under control while the colony is being operated.

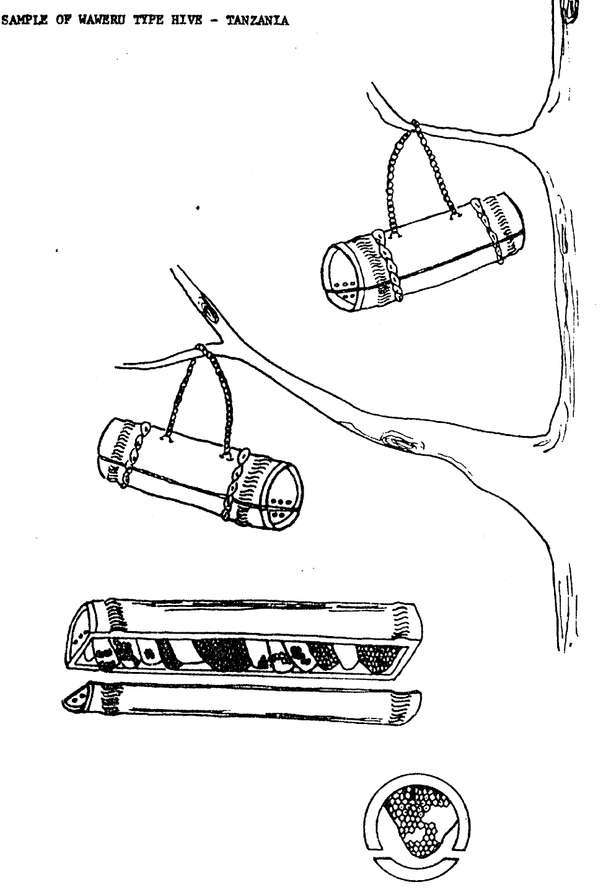

The Cylindrical Split Hive

Perhaps the first hive that should be used and recommended as a start is the cylindrical hive, with the lower one-quarter split so that it can be removed and the combs that have honey taken out readily. This hive can be made of any cylindrical material, a hollowed-out log, a thick bamboo stem, or even clay. It should be about 30 cm across and about 90 cm long. If bamboo thick enough can be found then the node in the bamboo could be used for an end, as each end should be closed and one of them should have holes in it for the entrances. The inside of the cylinder should be rubbed with beeswax or a beeswax-propolis mixture at the top to attract the bees. Since many of the beekeepers presently use cylindrical hives of this nature, they perhaps could be taught to split them on the bottom so that they can remove the honey quite readily. They would be encouraged to do so if the honey was bought from them on a graded basis.

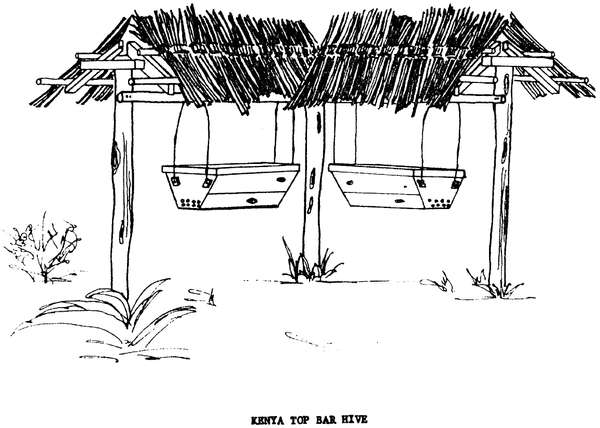

Kenya Top Bar Hive

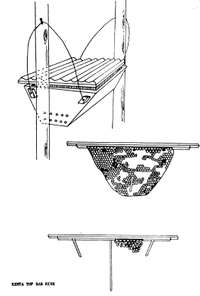

(NOTE by ECHO: This is also called the African hive.) In Kenya a modification of the Greek basket hive with movable top bars, which is now called the Kenya top bar hive, is successfully replacing the traditional log hive with fixed combs. The hive was tested on an extensive scale by Mr. Jim Nightingale, of Njoro, Kenya, and proved to be quite successful for Kenya conditions. With this hive it is possible to remove the frames which contain only honey. The major drawback, which restricts its use to stationary-type beekeeping, is that the combs will break away from the top bar quite readily. The combs must be suspended vertically at all times; if the bar is rotated so that the comb is horizontal, the weight of the comb may cause it to break from the bar. To harvest the honey and beeswax, remove the combs that contain fully capped honey but no pollen or brood.

(NOTE by ECHO: This is also called the African hive.) In Kenya a modification of the Greek basket hive with movable top bars, which is now called the Kenya top bar hive, is successfully replacing the traditional log hive with fixed combs. The hive was tested on an extensive scale by Mr. Jim Nightingale, of Njoro, Kenya, and proved to be quite successful for Kenya conditions. With this hive it is possible to remove the frames which contain only honey. The major drawback, which restricts its use to stationary-type beekeeping, is that the combs will break away from the top bar quite readily. The combs must be suspended vertically at all times; if the bar is rotated so that the comb is horizontal, the weight of the comb may cause it to break from the bar. To harvest the honey and beeswax, remove the combs that contain fully capped honey but no pollen or brood.

Mr. Jim Nightingale has found recently that if three small holes, about 2.5 - 3 mm in thickness, are drilled through the top bar, the center one being at a 90° angle with the top and the other two sloping inward, then three 2.5 mm strips of wood or bamboo can be passed through these as depicted. When the comb is drawn out over these sticks, the comb will be strong enough to withstand transportation. If it is desired to transfer these combs to another type of hive, in most cases they will fit. At the most, some of the comb can be cut off the bottom.

Mr. Jim Nightingale has found recently that if three small holes, about 2.5 - 3 mm in thickness, are drilled through the top bar, the center one being at a 90° angle with the top and the other two sloping inward, then three 2.5 mm strips of wood or bamboo can be passed through these as depicted. When the comb is drawn out over these sticks, the comb will be strong enough to withstand transportation. If it is desired to transfer these combs to another type of hive, in most cases they will fit. At the most, some of the comb can be cut off the bottom.

This type of hive can be equipped with a frame-type feeder and a queen excluder made of coffee wire with 0.5 cm mesh, placed in the center of the box, although there is no real need for a queen excluder in this type of management. If the hive is made carefully from dried lumber, all of the parts should fit well so that the bars together form a complete cover. It should, therefore, be necessary to keep only one opening and the entrance under control with smoke when examining the colony. The hive can be suspended with wire from each end, between posts or between trees. The wire should be covered with grease so that ants cannot readily travel on the wire. The hive should be placed at working height that is sufficiently high to protect it from honey badgers. If the badgers climb the poles it may be necessary to wrap the poles with metal. The hanging blocks should be low enough on the sides so as not to interfere with the lid. The wires should be almost vertical so that the colony may be lifted from either end to determine the presence of honey.

Two pieces of wood that have the same length and thickness as the top bars, but are narrower, are placed at the end of the series of frames to block any openings before the lid is replaced. They can protrude onto the end of the box, as the ends should be level with the beveled edge of the side.

Hive beetles can be controlled if no entrance alighting board is used, and 12-mm holes are drilled about 25-35 mm above the floor as an entrance for the bees. This size of opening will keep out the large beetles, and the small beetles seem to need an alighting board to enter the hive.

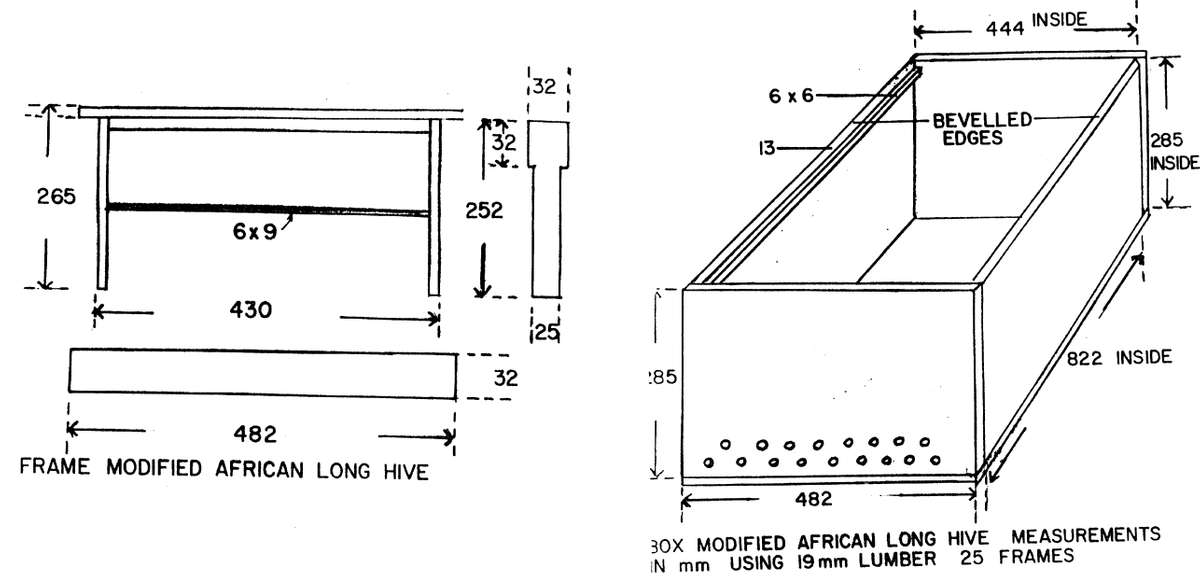

The Modified African Long Hive

The hive is operated and hung in the same manner as the Kenya top bar hive. A queen excluder and frame feeder can be used if wanted. The combs can be extracted in a centrifugal frame extractor, and the wax later cut out; or the wax can be cut out and the honey removed by dripping. If the comb is extracted it can be replaced intact, if so desired, when the honey flow is still under way. The lid is best covered with corrugated iron, but other waterproof materials can be used.

In the construction it is important to bevel the upper edge of the box, sloping downward to the outside of the box as a frame rest, since the frames do not quite reach the outside edge. If they were longer they would not fit the Langstroth hive. A strip of wood 6.5-mm square, placed 13 mm below the frame rest, is necessary to center the frame and to provide the bee space on the sides, as none is available at the top. Two pieces of wood that have the same length and thickness as the top bars, but are narrower, are placed at the end of the series of frames to block any openings before the lid is replaced. These pieces protrude onto the end of the box, as the ends should be level with the beveled edge of the side similar to the Kenya top bar hive.

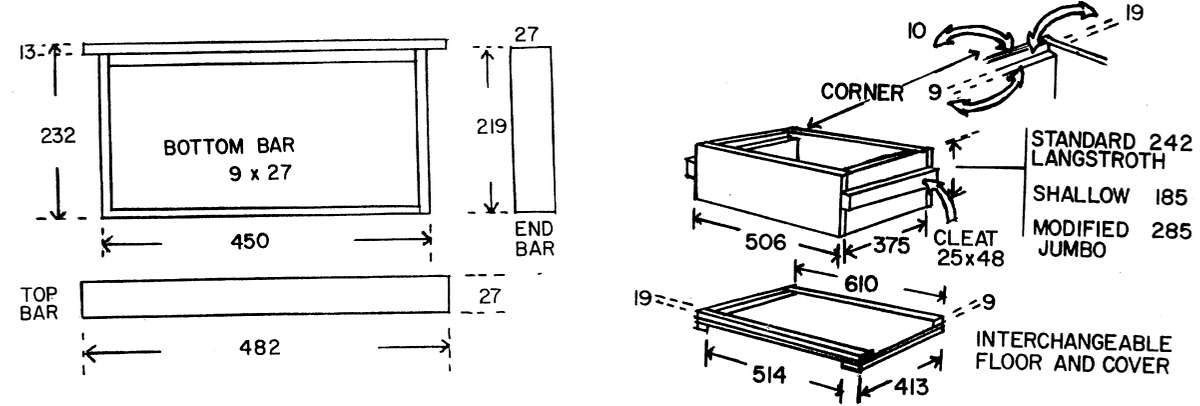

Simple Ten-Frame Langstroth Hive

Where the strains of the bee are gentle, where there are few predators (particularly ants), where facilities are available for precise cutting of the parts, and where there are good extension services and subsidization or credit available, then the Langstroth type hive is the logical choice. These circumstances are usually found only in the more temperate areas. The Langstroth hive is also advisable for some types of research, particularly into queen and bee production and improvement.

The design presented is as simple as possible for manufacture, with the least amount of special equipment. The cleats in place of help to give rigidity to a butt end joint. The interchangeable top and bottom boards help to simplify manufacture, but are not necessary as other designs can be used.

Three depths of hive body are included. The standard Langstroth depth is suitable for a two-box brood chamber system where interchangeability is desired, and is usually accompanied by supers in the same depth. For a one-box brood chamber, the modified jumbo depth is the most convenient, accompanied by the shallow super. The shallower super is also valuable where the boxes of honey must be transported over rough roads.

| Standard Langstroth Hive Frame | |

| Standard Farme Depth | 232 mm |

| Shallow Frame Depth | 185 mm |

| Modified Jumbo Frame Depth | 285 mm |

The depth of hive most suited for tropical areas would be the modified jumbo type with the shallow super, or if the Kenya top bar hive or the modified African long hive had been in use as well, then the standard Langstroth super could be used and the frames for the modified African long hive or Kenya top bar hive would fit into the Langstroth super quite readily. The measurements given are the new recommendations for standard hives, based on the latest metric lumber sizes.

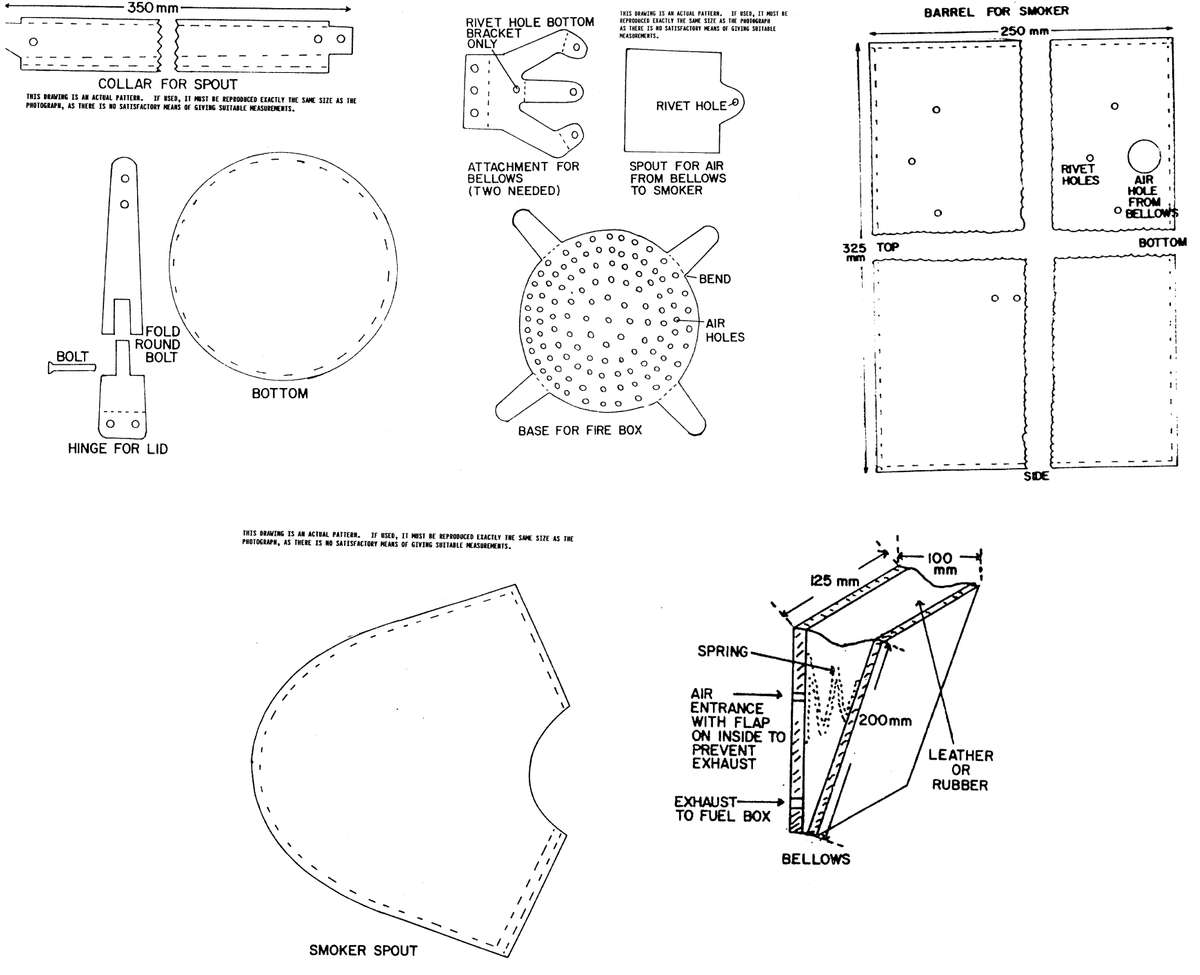

Protective equipment

Of the protective equipment perhaps the smoker is the most important. It is necessary to have some type of a contained smoker from which directed smoke will come. The best, of course, is the traditional type smoker used in western beekeeping, but with a large type firebox where African bees are involved. This type of smoker is best made in a workshop equipped with tinsmithing equipment, although following a pattern they can be made from old metal containers with no special tools. If possible, this is the type of smoker that should be provided under all circumstances. Other simpler, homemade smokers can be constructed, such as a metal can with holes in the side and a tube at each end, one to blow in.

Smoker fuels are also a consideration as they should burn over a long period of time and produce sufficient smoke. This can consist of shavings, sacking, or the fiber from the outer husks of coconuts; dried elephant or cow dung is also quite useful. If sacking is to be used, then one must be careful that it has not been contaminated with poisonous chemicals. Always light the smoker at the bottom. After it is burning well add sufficient fuel material to slowly smolder and provide a cool, continuous smoke with no sparks.

Since it is much more practical to work with the bees during daylight, other protective equipment is also necessary, particularly a veil. It is certainly best to use the veils prepared for beekeeping, but sometimes these are expensive to the beekeeper. He can make one out of mosquito netting in the shape of a bag approximately 75 cm long, which can be slipped over a wide-brimmed hat, and the end of the netting tucked inside his clothing. Since, in most cases, mosquito netting is white, the front part of the area where you look through should be dyed a dark blue or black with ink so that one can see through it much easier. The next important item is the clothing. White or light-colored clothes with long sleeves, and trousers tucked into the tops of boots (bees like to attack your ankles), keeping in mind that bees will crawl into any openings and especially like to move upwards. Under many circumstances, particularly with African bees, it is also advisable to wear gloves. The gloves should be long enough in order to cover the sleeves as well. If the gloves are homemade out of some type of canvas, they should be soaked in linseed oil and left to dry, repeating the same procedure once or twice. A tool to pry frames apart or cut the edge of combs is essential. In most cases a strong knife would be as good as the traditional hive tool used in the west, except where Langstroth type equipment is used. Never use black clothes, as most bees (particularly African strains) do not like black cloth.

Smoker Plans:

Wood Preservatives

In tropical areas it is necessary to either use wood which is resistant to termites or ants, or to treat the wooden parts of the hive. If you wish to stay away from using any of the wood preservatives, the equipment may be dipped in a very hot solution of paraffin wax for a two-minute period. The temperature should be in the neighborhood of 158°C. Sometimes up to 50% rosin or some beeswax may be added to this mixture. This procedure is dangerous unless special equipment is devised for the dipping and the heating. The only wood preservative, which is relatively non-toxic to bees, is copper naphthanate. In any event, any beekeeping equipment treated with a wood preservative should be allowed to dry well and air before being used. If paint only is desired, then the best material is an oil-base paint containing aluminum. In tropical areas it is necessary to select the type of wood carefully unless a good preservative is used. In many of the tropical areas Pinus radiata is more readily available and is certainly a lighter wood to handle that some of the others. This wood must be treated in some manner and the copper naphthanate treatment is recommended, possibly along with paraffin wax treatment. The oil-based aluminum paint is also reasonably satisfactory but will not last as long as the others.

Useful Resources

The Hive and the Honey Bee. 1986. Dadant & Sons (eds.). 740 pp.

Langstroth Hive Plans. On line. http://www.piteraq.dk/bier/beehive.html

Beehive Plans. On line. http://www.renovation-headquarters.com/plans-beehive.html