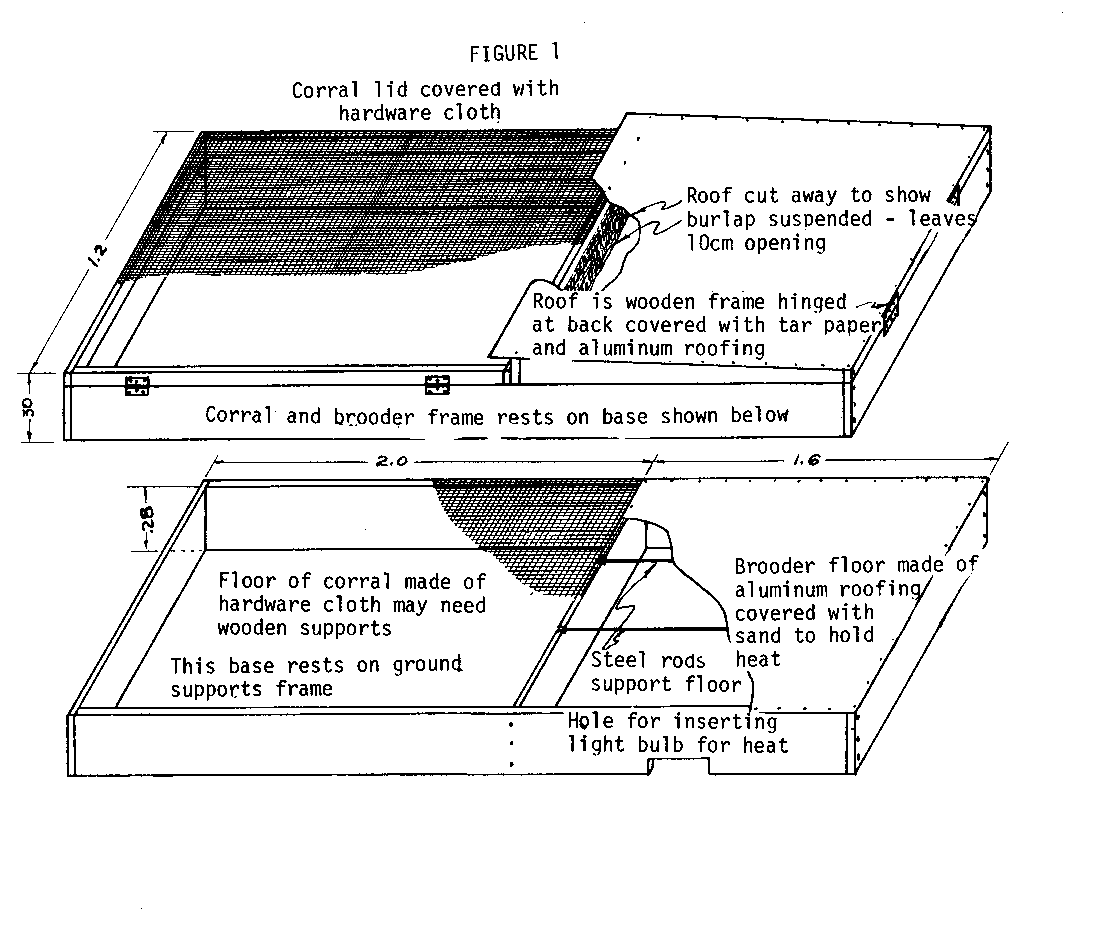

BROODER WITH CORRAL FOR 200 CHICKS

This chick brooder (see Figure 1) is hinged for easy access to corral and brooder.

The brooder has been used successfully in Ecuador and elsewhere to raise broilers for a cash crop.

The brooder is heated by a regular electric light bulb, placed under the brooder floor. Depending on the temperature rise required, the wattage of the light bulb will have to be chosen by experimentation. The metal floor and roof prevent predators such as rats from entering the brooder. If electric power is not available, an excavation can be made for a lantern. Be sure the lantern has adequate ventilation.

Tools and Materials

Small carpentry tools Hardware cloth 1.2 x 2m (4' x 6' 6 3/4"), 2 pieces this size needed. Aluminum roofing: 1 piece: 1.2m x 1.6m (4' x 5'3") 1 piece: 1.2m x 1.7m (4' x 5'7") Wood, approximately 30cm x 2cm x 20m (1' x 3/4" x 65'8") Steel rod 1cm (3/8") diameter x 3.2m (10' 6") 4 hinges about 8cm (3 1/8") long Woodscrews for hinges 2 buckets clean dry sand Nails, tacks, staples

Source:

Kreps, George. Article in Rural Missions, #122, Agricultural Missions, Inc.

KEROSENE LAMP BROODER FOR 75 TO 100 CHICKS

This brooder has been used by more than 300 farmers in eastern Nigeria.

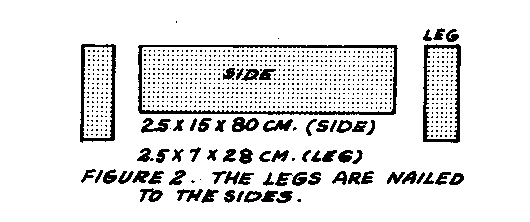

Nail legs to side (see Figure 2). If

desired, make the height of the brooder adjustable by drilling a row of holes in each leg and bolting the legs to the sides.

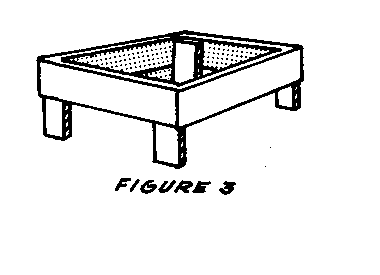

Assemble and nail top support rails 1cm (3/8") below the upper edge of the sides (see Figure 3).

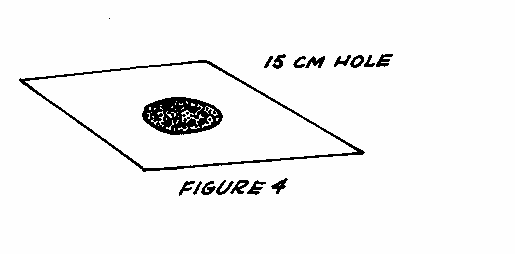

Make the top of plywood, sheet metal, or wooden boards so that the top fits inside the frame and rests on the support rails (see Figure 4). The hole in the

center of the top is for ventilation. A swinging metal cover regulates the size of the opening.

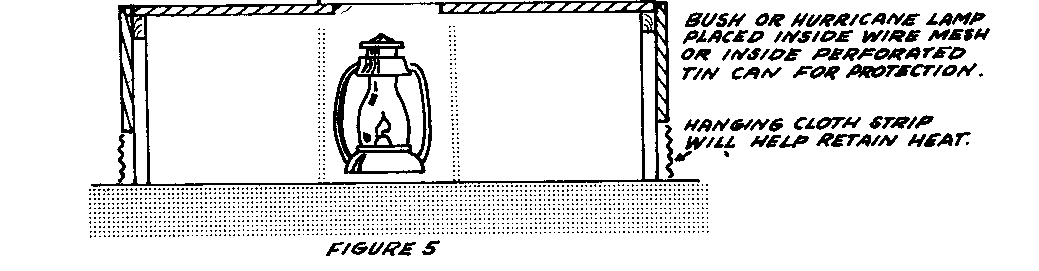

A bush or hurricane lamp is placed inside wire mesh or a perforated tin can to protect the chicks and to help radiate the heat (see Figure 5).

The dimensions given in the illustrations can be altered slightly to use available materials.

The wicks of the lanterns should be cleaned daily to cut down on soot.

Source:

W. H. McCluskey, Poultry Science Department, Oregon State University, Corvallis.

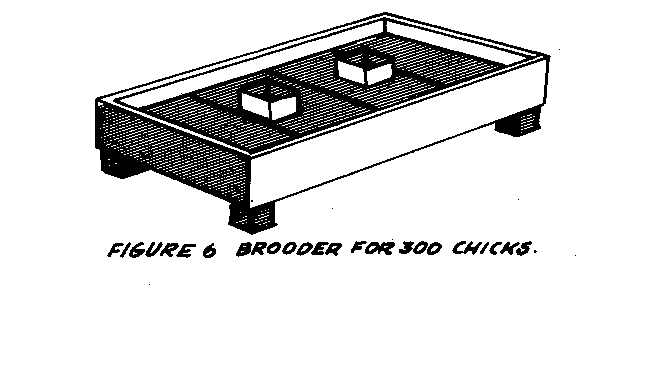

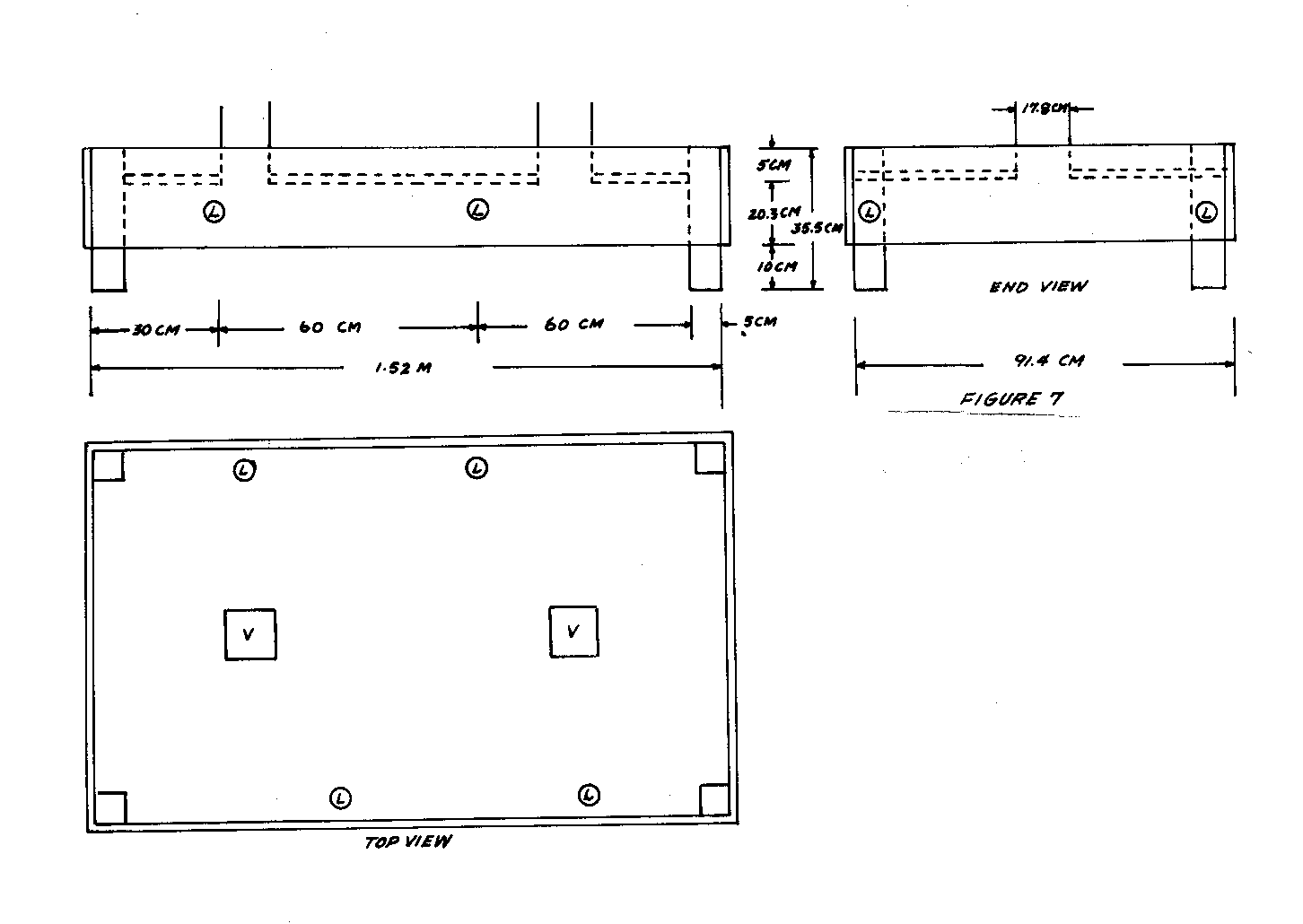

BROODER FOR 300 CHICKS

This brooder (see Figure 6) is similar to the other two brooders. It can be used

with either lanterns or electric light bulbs. If lanterns are used, their wicks should be cleaned daily. Construction details are given in Figure 7.

Source:

Stopper, W.W. "Brooder for 300 Chicks". New Delhi: U.S. Technical Cooperation Mission to India. (Mimeographed).

BAMBOO POULTRY HOUSE

This bamboo poultry house has a thatch roof and slat walls to provide good ventilation. The elevated slat floor keeps chickens clean and healthy while the egg catch and feed troughs simplify maintenance. It has been used successfully in the Philippines and Liberia.

Tools and Materials

Bamboo Nails Thatching materials Small tools

House

The house is built on a frame of small poles, with floor poles raised about 1m (3') from the ground. (See section on construction with bamboo, p. 302.) The floor poles are covered with large bamboo stalks, split into strips 38mm (1 1/2") wide, spaced 38mm (1 1/2") apart. Floors so constructed have several advantages: better ventilation, no problem of wet moldy litter during rainy reason or dry dusty litter during dry season; droppings fall between split reeds to ground away from chickens. This eliminates parasites and diseases normally passed from hen to hen through droppings remaining warm and moist in litter. However, it has been suggested that wide spacing of floor and wall slats might invite marauders such as weasels and snakes.

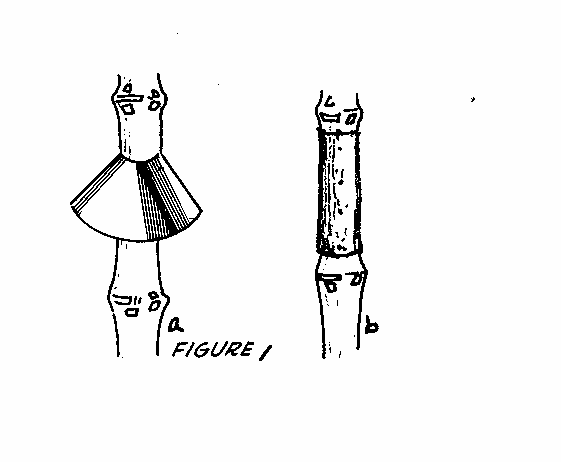

Metal shields on all the support poles will keep rats and other pests from climbing (see Figure 1a). Be sure you don't inadvertently leave a hoe or other

tool leaning against the house, or the rats will climb that. (Note: A VITA grain storage project in Central African Republic has had good results protecting granaries-not poultry houses-with a flat band of metal [Figure 1b] that is simply wrapped around each granary support. This kind of guard is cheaper and easier to install and maintain than the flared collar. Make the guard about 25cm wide and about 20 cm from the ground. You may have to experiment a bit to match the size and placement of the guard to the size and climbing ability of the rats in your neighborhood.)

Walls are made from vertical strips of bamboo 38mm (1 1/2") wide, spaced 6cm to 8cm (2 1/2" to 3") apart. This also allows ample ventilation, needed to furnish oxygen to the chickens and to allow evaporation of excess moisture produced in the droppings. In the tropics the problem is to keep chickens cool, not warm. Using a dosed or tight-walled poultry house with a solid floor would keep them too warm and result in lowered production and increased respiratory problems. Shade over and around these houses is very important. If the ground around the houses is not shaded, heat will bounce into the houses.

Roof

The roof must protect the chickens from the weather. In Liberia thatch roofing keeps the birds cool, but it must be replaced more often than most other materials. Since it is cheap and readily available to the small farmer or rural family, it is most likely to be used. Aluminum, which reflects the heat of the sun, and asbestos, an efficient insulator, are desirable roofing materials in the tropics. Zinc, which is commonly used to roof houses in Liberia, is undesirable for chicken houses because it is an efficient conductor of heat.

Whatever the roofing material the roof must have an overhang of 1m (3') on all sides to prevent rain from blowing inside the house. It may be desirable to slope the overhang toward the ground.

Feeders

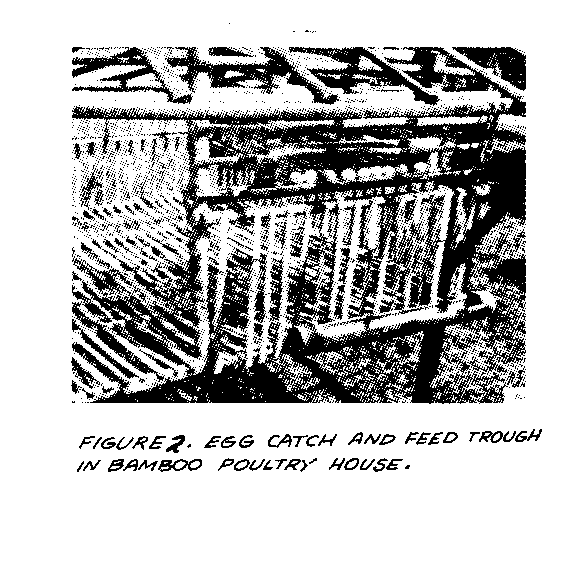

Feeders and waterers are made from 10cm to 12.5cm (4" to 5") diameter bamboo of the desired length (see Figure 2). A node or joint must be left intact in each

end of the bamboo section to keep the feed or water in. A section 7.5cm to 10cm (3" to 4") wide around half the circumference of the bamboo, except for 7.5cm (3") sections on the ends, is removed to make a kind of trough. All nodes between the ends are removed. These feeders must be fastened at the base, to keep them from rolling.

The feeders are fastened to the outside of the walls about 15cm (6") above floor level. The hens place their heads through the bamboo strips to feed or drink, thus conserving floor space for additional chickens.

Nests

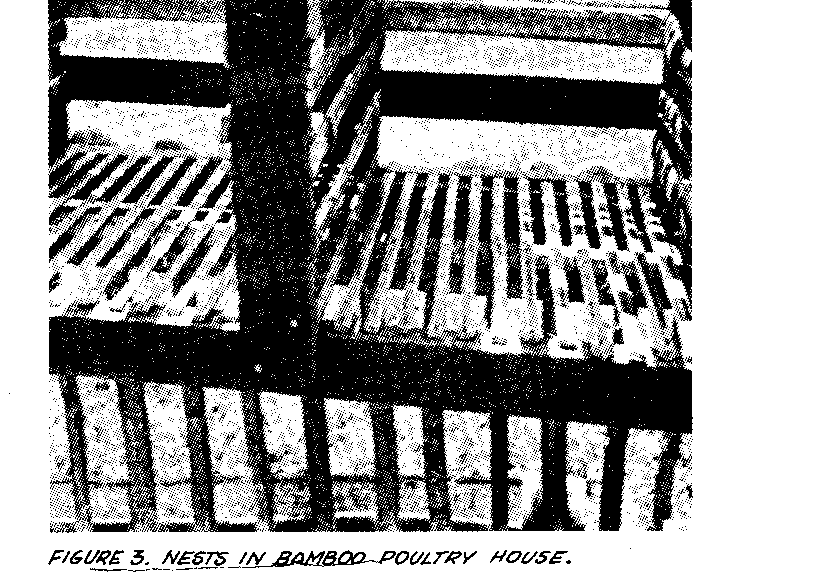

The demonstration nests are 38cm (15") long, 30cm (12") wide, and 35.5cm (14") high (see Figure 3). The strips used on the floor of the nest are about 13mm (1/2") wide, spaced 13mm (1/2") apart, and must be very smooth. The floor slopes 13mm (1/2") from front to back, so that when the eggs are laid they will roll to the back of the nest. An opening 5cm (2") high at the back of the nest allows the eggs to roll out of the nest into an egg catch (see Figure 1). This type of

nest results in cleaner eggs and fewer broken eggs. It also yields better quality eggs because they begin to cool as soon as they roll out of the nest. In addition, the eggs are outside the nest where egg eating hens cannot reach them. Placing the egg catch so it protrudes outside the wall of the house allows the eggs to be gathered from outside. Placing the nests 1 meter (3') above the floor conserves floor space and permits more laying hens to be placed in the laying house. One nest is put in for every five hens.

In laying houses, nests are also constructed of split bamboo for unobstructed ventilation. Conventional lumber nests are hotter; this may cause hens to lay eggs on the floor instead of in the nests. This means more dirty eggs, more broken eggs, and more likelihood of the hens eating the broken eggs. The only way to cure a hen of eating eggs once the habit is formed is to kill her. In addition, as the hens enter the nests they sit on eggs laid previously by other hens, keeping them warm. The quality of eggs deteriorates very fast under these conditions.

Source:

USAID, Monrovia, Liberia, described in OTS Information Kit, vol. 1, No. 5, May 1961.

POULTRY FEED FORMULAS

Ingredients--Ceylon Percentage required for Layers

Sorghum 42.0 Rice bran 19.5 Fish meal 8.5 Coconut meal 18.5 Gingelly (sesamus indicum) cake 2.0 Cowpeas 3.0 Shell grit 6.5 Salt 0.5

TOTAL

100.5

Added per 100.5 kg: Potassium Iodide (g) 0.145 Choline Chloride (21.7%)(g) 540

Ingredients--Congo Percentage required for Layers

Maize ground 20.0 Millet, ground 18.0 Rice, husk, ground 10.0 Fish meal 4.0 Meat meal 5.0 Groundnut cake meal 25.0 Lucerne meal 12.0 Dicalcium phosphate 2.0 Oyster shells 3.0 Salt 1.0

TOTAL 100.0

Ingredients--Uruguay Percentage required for Layers

Ground maize 40.0 Ground wheat 5.0 Sorghum 3.0 Ground barley 20.0 Bran 10.0 Meat meal 7.0 Ground sunflower cake 10.0 Oyster shells 4.0 Salt 1.0

TOTAL 100.0

Compiled by Harlan Attfield, from Poultry Feeding in Tropical and Subtropical Countries, Food and Agriculture Organization of the United Nations, Rome.