VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Agricultural Waste Recycling ISBN: 0-86619-209-3 [sup.c]1984, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Leslie Gottschalk and Maria Giannuzzi as editors, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

VITA Volunteer Walter Eshenaur, the author of this paper, is a research assistant in the Department of Agricultural Engineering at the University of Minnesota, where he specializes in energy technologies. Dr. Eldridge Collins, one of the reviewers of this paper, is with the department of Agricultural Engineering, College of Agriculture and Life Sciences, Virginia Polytechnic Institute and State University. VITA Volunteer reviewer Philip R. Goodrich is an Associate Professor with the Department of Agricultural Engineering, University of Minnesota. VITA Volunteer reviewer Martin Wulfe is a consultant in the field of energy development. He has performed several consultancies in renewable energy assessment in Africa, Indonesia, and West Sumatra. Wulfe has also published several articles and a section in a book on energy.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Agriculture is the most important direct source of livelihood and the largest source of employment in the world's less developed countries. The agriculture sector produces food crops, meat and other animal products, energy crops, and industrial crops. It also produces billions of tons of other materials long regarded as "waste." The main types of agricultural waste are crop residues, the parts of crop plants that are not eaten, and farm animal waste products. In the past, the vast majority of these materials was indeed wasted.

Agricultural experts are coming to recognize that agricultural residues can be thought of as a "resource out of place" instead of simply waste or by-products. This is a very important change of perspective which permits the evaluation of waste from a positive standpoint. Once an evaluation of waste is embarked upon, it becomes obvious that this resource represents a partial solution to the energy dilemma facing agriculture today. Once the agricultural waste resource is understood as a tremendous source of energy, then steps to utilize this energy may be taken.

With appropriate techniques, agricultural wastes can be recycled to produce an important source of energy and natural fertilizer for crops. Recycling agricultural wastes can help a developing country reduce its dependence on foreign energy supplies and raise the standard of living in its rural areas.

This paper discusses the general theory involved in recycling agricultural wastes and several popular methods. It does not present detailed practical examples. It is important to stress that the choice of recycling method will depend on the type of waste available and on the end use the farmer has in mind for the recycled waste. It is hoped that readers will adapt the general methods discussed in this paper to their own local conditions.

KINDS OF AGRICULTURAL WASTE

The main kinds of agricultural waste are crop residues and farm animal waste. Most of the energy contained in crop residues is in the form of carbohydrates and cellulose. Table 1 shows the chemical composition of some residues.

Table 1. Composition of Some Residues

Grain Leaf Citrus Manure straw (grass) pulp (poultry)

Dry Matter: Organic matter 95 91 93 77 Ash 5 9 7 23 Crude protein 3 17 7 32 Crude fiber 48 27 14 -- Nitrogen-free extract 43 44 69 27

Source: P. van der Wal, "Perspectives on Bioconversion of Organic Residues for Rural Communities, "Proceedings of Bioconversion of Organic Residues for Rural Commuinities (Tokyo, Japan: United Nations University), 1979, p. 5.

All the residues in Table 1 contain mostly organic matter. In developing countries, poultry generally are allowed to forage and digest much of the organic matter ingested. Thus, poultry do not produce as much organic matter as crop residues. Ash is the waste that remains unused even after the most rigorous of recycling processes. The main content of ash is inorganic substances such as potassium and phosphorus. Energy extraction from crude protein is difficult but is very useful for animal or human consumption since in this way the protein may be utilized. Crude fiber may remain somewhat unused if fed to some animals. However, if digested aerobically (in the presence of oxygen), anaerobically (in the absence of oxygen), chemically (using alkali or ammonia) or through composting, crude fiber will break down to simpler carbohydrates that are easily digested either by animals or in the soil.

The amount of nitrogen-free extract indicates how much nitrogen is available. Comparing amounts of organic matter and nitrogen-free extract indicates approximately how much nitrogen is made available through digestion or chemical treatment. A higher percentage of nitrogen-free extract indicates a lower percentage of available nitrogen and vice versa. Nitrogen plays an important role in soil conditioning and refeeding to animals since it is a necessary nutrient for both. Nitrogen also plays an important role in aerobic and anaerobic processes;however, these processes change the form of nitrogen, which may influence its availability to plants, volatility, or leachability.

Grain straw represents the largest component of crop residues. As indicated by Table 1, large part of grain straw is crude fiber. Thus the method for recycling grain straw should include some type of decomposition process to extract maximum energy. Grass, although easier to digest, should receive somewhat the same treatment as grain straw.

Citrus and vegetable residues are relatively easy to digest and direct methods of extracting energy such as refeeding or soil incorporation work well. However, due to the ease of digestion, other forms of energy such as methane or alcohol may utilize these residues more fully since the decomposition process is more complete. In conclusion, when recycling crop residues, some type of decomposition treatment is desirable.

ANIMAL WASTES

Animal waste includes manure (feces and urine) along with added bedding, other liquids, and soil. Other wastes such as milkhouse and washing wastes, hair, and feathers may also be included within this category.

The composition of animal manure depends upon "animal specie; digestibility, protein, and fiber contents of rations; and animal age, environment, and productivity" (Midwest Plan Service, 1975).

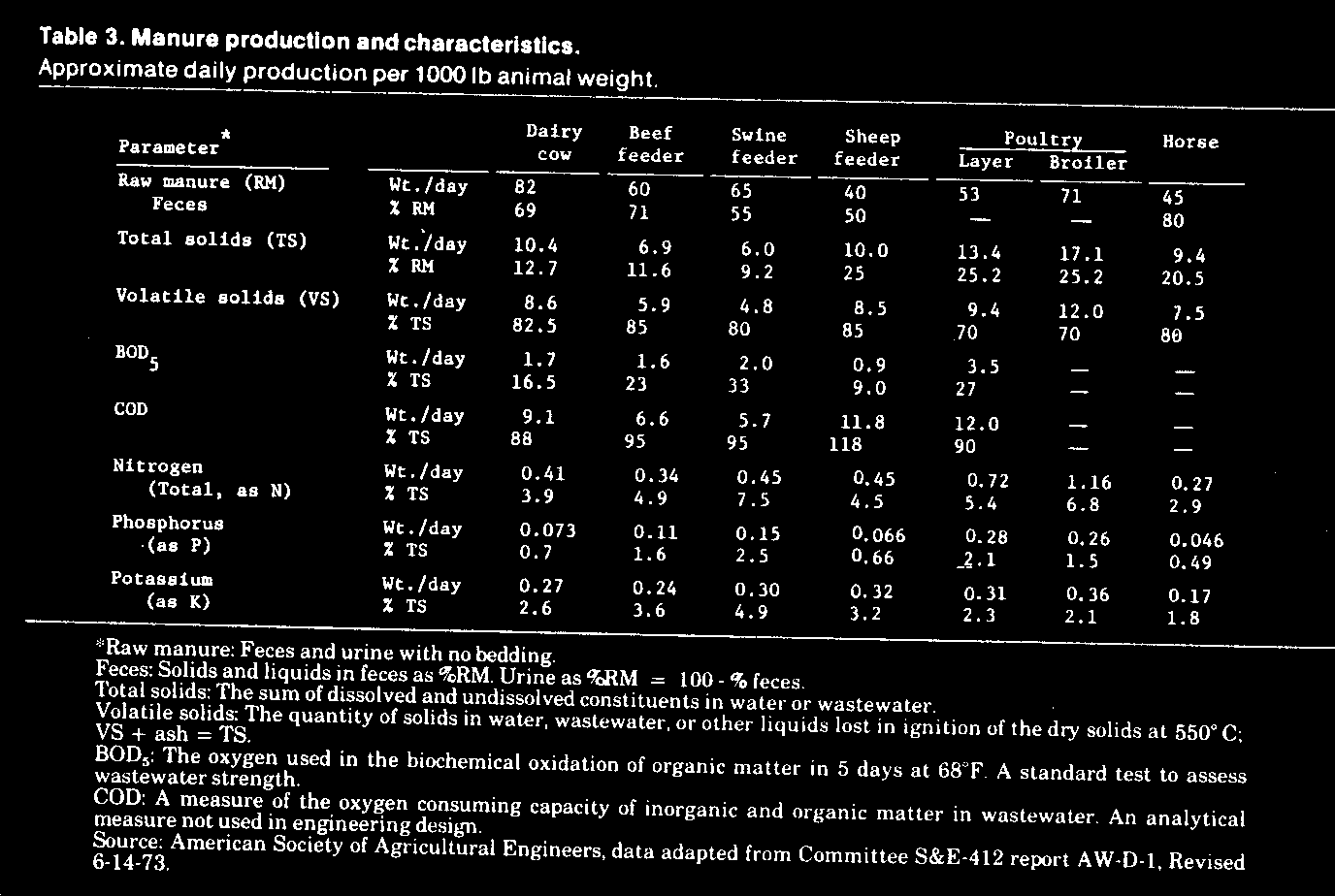

Due to varying diets and wastes, only estimates can be given for properties and nutrient content of manure. Table 3 shows manure

production and characteristics of some popular animals.

Explanations of Table 3 are as follows. Raw manure includes feces and urine without bedding. Feces refers to the solids component of manure. Percent raw manure (percent RM) is the percentage of the raw manure that is made up of feces. Total solids is the sum of dissolved and undissolved components of the manure. Volatile solids refers to the amount of material that will burn or become volatile under a temperature of 550 degrees Centigrade. The oxygen used for the biochemical oxidation of organic matter is referred to as the Biological Oxygen Demand (BOD). The five (5) refers to the BOD after five days in a 20 degrees Centigrade environment. The Chemical Oxygen Demand (COD) is not used in engineering design but represents the total oxygen demand if all inorganic and organic material is oxidized. The COD will always be a higher value than the BOD.

The main emphasis of Table 3 is to show the various properties of different animal manures. It is clear that varying manures differ in all categories and recommendations may be made as to what recycling process could be used with each manure.

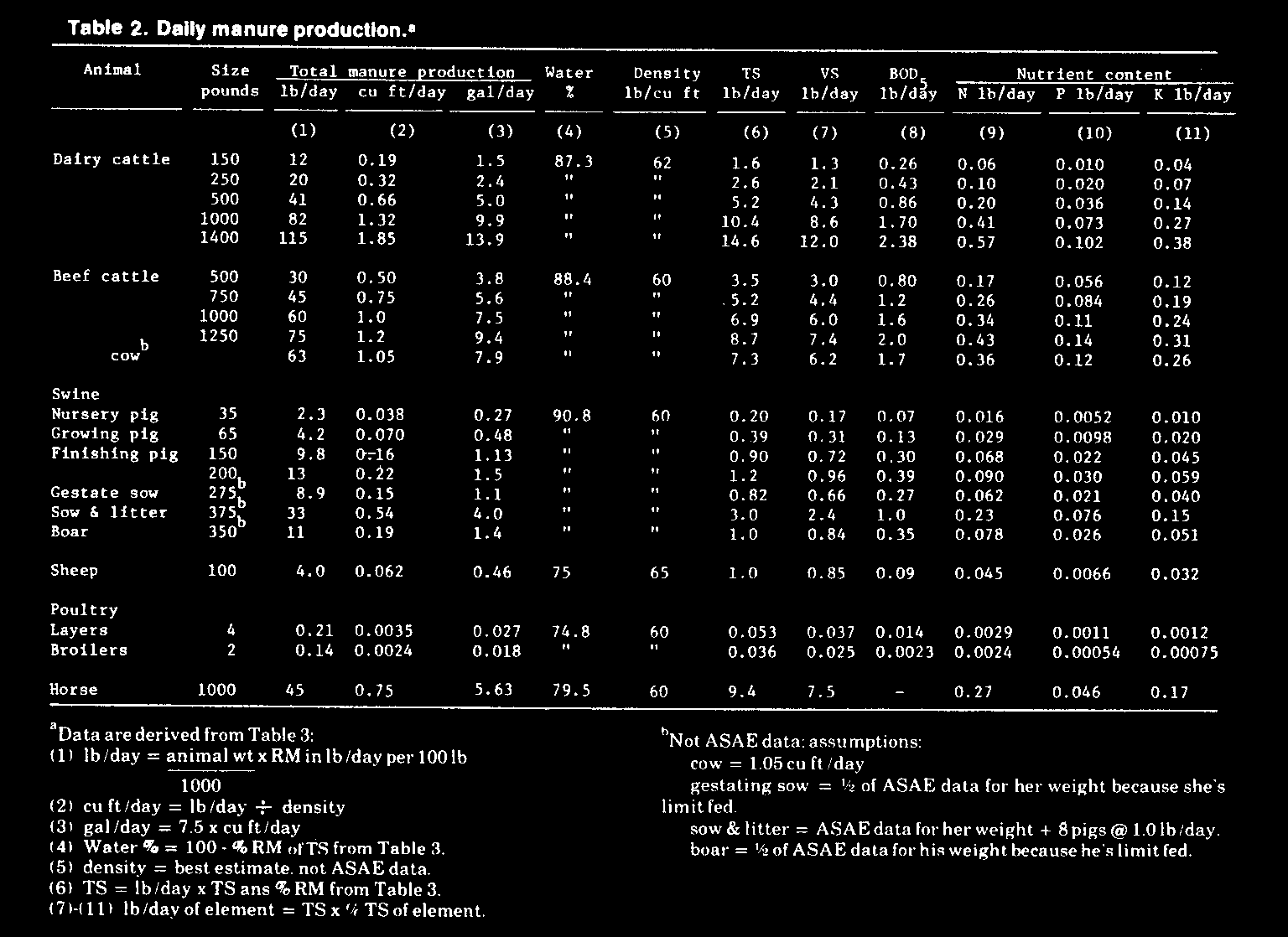

Table 2 shows daily manure production and is somewhat more detailed

than Table 3. Explanations for total solids, volatile solids and BOD are the same as for Table 3.

Dairy cattle produce more manure than any other individual animal; poultry produce the least. However, if production per unit weight is calculated, poultry produce almost as much as any other animal. Poultry manure also contains less water than others. Total solids and BOD are quite high for poultry, but so are volatile solids. Thus, although poultry manure production is slightly lower than that for cattle (per unit weight), its total solids or decomposable material is higher. This is a positive characteristic for aerobic and anaerobic digestion even though the BOD is rather high. Dairy manure is also high in total solids and therefore provides good digester input (influent). The ratio of BOD to total solids is high for swine (0.32) and gradually decreases from poultry (0.26) to beef (0.23) to dairy cattle (0.16). This ratio indicates the relative amount of oxygen necessary to decompose the solids. A high number suggests high oxygen use and a low number suggests low oxygen use. Thus, for bacterial processes that require oxygen (most common ones do), dairy manure will decompose with less oxygen input than will swine manure. For decomposition such as aerobic digestion, direct land application, or composting, dairy manure will provide more decomposed matter and thus more nutrients per unit time than will swine manure. In the controlled decomposition of anaerobic digestion, oxygen deand is not important because it is not used to a large extent. However, oxygen demand does reflect indirectly the amount of organic matter present. A higher oxygen demand suggests a higher organic matter content and vice versa.

Data in Tables 2 and 3 were developed by the American Society of Agricultural Engineers based on work reported in the literature and represents American or European feeding methods. These data may vary by up to 20 percent for animals in confined or semi-confined quarters. For animals that are on a total forage diet (i.e., pasture grazing), the data for a beef cow will be most accurate. They will probably give values that are too low, except for nitrogen, which may be high.

Drying of manure is also used for some recycling processes. Table 3 shows that swine manure contains the highest water content and poultry manure the lowest. Thus for drying it is better to use poultry than swine manure.

Nutrient content is an important value in determining which manure will provide the best refeeding or land application capabilities. Table 4 shows relative nutrient qualities.

Table 4. Nutrients Per Manure Quantity

Element Element pound/1000 gal. manure pound/ton raw manure

N P K N P K

Dairy 41 7.4 27 9.9 1.8 6.6 Beef 45 15 32 11.4 3.7 8.4 Swine 55 18 32 13.8 4.6 9.0 Sheep 97 14 69 22.5 3.3 16.0 Poultry: Layer 109 42 47 27.2 10.6 11.6 Broiler 131 29 41 34.3 7.6 10.6 Horse 48 8 30 11.8 2.0 7.4

Source: Midwest Plan Service, 1975, p. 5.

Nutrient levels are given only for nitrogen (N), potassium (K) and phosphorus (P). Other nutrients are minor and are either almost totally lost during decomposition or are comparatively unimportant.

Land application requires that as many nutrients as possible remain in the soil after decomposition. In fact, the highest nutrient content will be without decomposition. This is somewhat misleading, however, since nitrogen occurs in several forms, not all of which are available to be used by plants. The best form of nitrogen is ammonia which is easily used by plants. The most efficient method of obtaining ammonia is anaerobic digestion, but the liquid effluent must be used immediately or the nitrogen is lost. Composting also produces ammonia but since the composting materials must be aerated, most of the ammonia is lost. Table 4 shows that only poultry manure is high in phosphorus. Phosphorus and potassium are stable inorganic compounds and are not used in most decomposition processes. Thus, both phosphorus and potassium will remain to be used in the soil after decomposition. Phosphorus is a necessary soil nutrient and usually more is needed than can be provided by animal manure. Thus, although nutrients necessary for recycling are present in animal manure, they are not sufficient to supply the total needs of the recycling process of most post recycling applications.

II. METHODS OF RECYCLING AGRICULTURAL WASTE

This section discusses five popular recycling methods: anaerobic digestion, refeeding, land application, composting, and incineration.

The choice of the best method depends on the type of waste to be recycled and the end use intended for the recycled waste. General methods discussed here must be adapted to specific local conditions.

Table 5 gives some potential end uses of organic residues.

Anaerobic Digestion

Anaerobic digestion is used to break down the starch and cellulotic components of crop residue to produce biogas for lighting or cooking. The decomposition of organic matter under anaerobic conditions produces amino acids, carbon dioxide, hydrogen sulfide, and methane. All these gases are either very toxic (hydrogen sulfide) or contribute to lack of sufficient oxygen (carbon and methane). Biogas under most circumstances will burn directly from the digester. For applications in internal combustion engines, the carbon dioxide and hydrogen sulfide must be removed. But removing these gases requires more complex technology usually not available in developing countries. Biogas will provide heat.

The aim of anaerobic digestion is to decompose as much organic matter as possible and produce as much biogas as possible. This requires a high quantity of degradable starch, and a little cellulose. Table 1 shows that grain straw, grass, and citrus residues are not the best organic materials. Animal manure, on the other hand, contains much degradable carbohydrates, has little cellulose, and has a relatively high nutrient level. More carbohydrates may be desired depending upon the type of animal manure being used. Table 1 shows that poultry manure is lower in organic material than crop residues and is higher in organic material than manure from swine or ruminants (cattle, sheep, and goats). Thus, crop residue alone is not desirable for the production of biogas; a mixture of animal manure and crop residue is most desirable.

Table 5. Potential End Uses of Organic Residues

Food microbial biomass fermented foods beverages mushroom production oils proteins

Feeds direct use upgrading (physical, chemical, microbial) ensilage microbial biomass

Fertilizer direct use compost residue of biogas production

Energy biogas alcohol producer gas direct use (combustion)

Construction boards materials panels bricks

Paper pulp paper paperboard packaging materials

Chemicals furfural xylitol alcohol organic acids polysaccharides

Pharmaceuticals hycogenin antibiotics vitamins

Source: W. Barreveld, "Availability of Organic Residues as a Rural Resource," Proceedings of Bioconversion of Organic Residues for Rural Communities (Tokyo Japan: United Nations University), 1079, p. 10. Nitrogen is an important nutrient in anaerobic digestion and usually some will remain after digestion is complete. Other by-products of anaerobic digestion include phosphorus, potassium, biogas, organic acids, alcohols, and cellulotic organic matter.

Advantages of anaerobic digestion include:

* low initial cost * low operating cost * simple operation (once process has started) * wide variation of loading rates * low nutrient requirement * useful end product: methane * effluent usable as soil conditioner

Disadvantages include:

* difficult starting procedure * foul odors * slow rate of microbial growth * best production at elevated temperatures

Anaerobic digestion is becoming more popular because of its increasing economic viability and improvements in technology. However, before any attempt to introduce anaerobic digestion into a particular culture, expert advice should be sought. Some cultures do not allow the handling of human wastes and may consider digestion as imposing on an already viable use. Great care must be taken in implementing this technology.

Refeeding

Refeeding of crop and animal wastes works well with ruminants because this family of animals can utilize the nutrients in their available form. The bacteria within a ruminant's stomach system break down non-protein nitrogen and utilize it as energy. Monogastric animals such as horses and swine cannot utilize this form of nitrogen and do not benefit from direct refeeding without prior treatment, except for protein utilization.

Some crop residues should be treated before recycling. Rice straw or bran will provide the necessary nutrients for livestock without processing. However, if soaked in an alkali bath, the digestibility of these crop residues increases almost twofold. This provides, for the same amount of roughage, a great increase in nutrient availability. It also allows animals to produce more milk or realize a greater increase in weight. Refeeding of leafy wastes works well and digestibility is good. However, as with grain residues, pretreatment is recommended, but not with alkali.

Any animal manure may be refed but poultry seems to be the most economical since it contains the highest nutrient concentration per unit weight. Crop residues are also good for ruminant refeeding but, as mentioned earlier, processing with alkali or ammonia will increase the digestibility greatly.

It is very important to process animal manure by drying or ensiling before refeeding to prevent pathogen transfer. Drying at elevated temperatures helps limit pathogen transfer and reduces the time from excretion to refeeding. Economically, refeeding of other than poultry manure is questionable and must be analyzed for each situation. Cultural taboos on feeding livestock other than pasture forage may be strong. Gaining acceptance may require a positive demonstration that supplementing pasture forage with dried or ensiled manure will indeed bring added nutrients and most likely healthier and strong animals.

Advantages of refeeding include:

- up to 75 percent of diet * no change in the taste of milk, meat, or eggs * weight gain remains the same or increases with 75 percent of diet

- good use of previously unused wastes

- Disadvantages include:

- feed conversion (conversion from roughage to nutrients) less than grams * pretreatment of crop residues necessary * drying of manure necessary * possible negative cultural or economic impacts

For situations where refeeding is culturally and economically acceptable, refeeding will increase nutrient levels and decrease dependence on imported feed.

Land Application

One of the most useful methods of recycling is reapplication of crop residues to the soil. Several methods are popular. The simplest method is reincorporation of residues into the soil following harvest. This eliminates the need for postharvest processing. Much nitrogen is lost, however, through volatilization of ammonia which is a product of decomposition. Also, if nitrogen-producing crops (i.e., legumes) are not grown, the soil will slowly lose all nitrogen since residues do not return enough to overcome the loss of nitrogen during the growing season.

A second method uses anaerobic digestion to reduce the crude fiber content yet retain nutrients necessary for soil conditioning. Once the digestion process is complete, the effluent is spread on the soil.

Several important practices must be adhered to in order to maximize nutrient retention in the soil. First, most nitrogen contained within the effluent is in the form of ammonia. Ammonia has a low vapor pressure and thus will evaporate quickly. Also, ammonia breaks down quickly in the presence of oxygen. To minimize the volatilization of the ammonia, immediate incorporation of the effluent into the soil is necessary. This practice of incorporation requires a labor- or energy-intensive system. In some situations this may not be possible.

Second, nightsoil and manure constitute better inputs for anaerobic digestion when combined with crop residues. Even with the rigorous decomposition that occurs in the digestion process, some pathogens and parasites can survive and enter the soil. This is very dangerous as these pathogens and parasites, such as hookworm, can eventually reinvade the human body. Care must be taken to ensure that as few pathogens as possible are transferred. The most effective method of preventing pathogen transfer is not to use nightsoil. Human pathogens are the most harmful and resistant to treatment. Another method is to operate the anaerobic digester at high temperatures. This will vastly reduce pathogen count. A third method would be to dry the effluent for an extended period of time. However, since ammonia is quite volatile, nitrogen loss would be substantial.

Crop residues and animal manure not only fertilize the soil, but also provide other benefits that are not immediately evident. Most tropical soils and intensely cultivated soils are poorly structured, so that the soil is hard and compacted. This in turn restricts water movement, plant root penetration, and nutrient transport, and increases surface erosion and tillage requirements. Adding crop residues along with animal manure increases soil aggregation dramatically. By increasing aggregation, the soil may be tilled more easily (or not at all in some circumstances), nutrient and water movement increases, and roots may penetrate deeper. Soil productivity is increased substantially while decreasing tillage needs.

A note of caution must be mentioned here. To raise the aggregation of the soil by a substantial amount, large amounts of residue must be used. Bulk density relates to the aggregation of the soil. Typical bulk densities range from about 1.00 (gram/cubic centimeter) for highly aggregated soils to 2.00 for very compact soils. To decrease the bulk density, the mass of solids must be decreased. This is accomplished by adding highly porous residues, thereby increasing the volume per unit mass. If the bulk density of one hectare of land 10 centimeters deep is to be reduced from 1.5 to 1.2, calculations show that 1,500 tons (metric) of residue must be added. This is a large amount and may take several years to accomplish. This simple example shows that soil conditioning through residue incorporation can improve soil properties but may take time to do so.

Advantages of soil conditioning include:

- increased soil nutrients * higher soil aggregation * less dependence on imported fertilizer * less tillage required * reduction of surface soil erosion * low capital investment * more soil moisture

Disadvantages include:

- large quantities required * residue pretreatment recommended * weed seed concentration * pathogen transport * labor intensive

Economic considerations would include handling and application procedures. This is a labor intensive method of recycling and may be marginally economical in most situations. Cultural acceptance is usually directly related to successful demonstration; mores are usually not an obstacle. For this recycling method to improve a situation, full cooperation of producers is important since large quantities of residue are required.

Composting

Composting is the practice of metabolizing residue by using aerobic microorganisms to break down organic matter into usable nutrients for application to the soil. Composting also decreases the bulk volume of residue, enabling easier transportation and handling.

Composting is accomplished by mounding residue and allowing natural heat buildup to start chemical metabolization of organic matter. This heat also eliminates pathogens and weed seeds and provides a stable, dry end-product.

For composting to be successful, certain methods must be used. Moisture content should be maintained at 50 percent by weight and a temperature of 60 degrees Centigrade maximizes decomposition. Mixing is important since composting is an aerobic process. If mixing is not possible, the composting process may take twice as long. Maintaining a pH between 7 and 9 will ensure proper and rapid metabolization. Carbon, nitrogen, and phosphorus proportions are important. A ratio of 25:1:2 respectively ensures rapid decomposition and stabilization. If manure is used, the carbon-nitrogen-phosphorus ratio will change, making addition of crop residues necessary. A ratio of 20:1 of crop residues to manure gives best results.

Advantages of composting include:

- organic matter metabolization * elimination of pathogens and weed seeds * uniform, dry end-product * no insect or rodent problem * no odor * excellent fertilizer and soil conditioner * low capital costs

Disadvantages include:

- loss of 50 percent nitrogen * labor intensive * high operating costs

Composting is used in many cultures around the world. Most cultures will accept composting as a viable method of obtaining nutrients. Composting is labor intensive and could be uneconomical from that standpoint. If labor is available, composting and then soil application is an excellent method of providing nutrients.

Incineration

Some crop wastes are best used for burning. Paddy husks and straw provide a substantial amount of energy when burned. Other crop residues may be best used in composting or refeeding, but grain hulls and straw provide large amounts of energy when simply burned.

In the paddy husk furnace, paddy husks and straw are burned with good aeration. The exhaust may be routed through a heat exchanger with the heated air used for drying grain, etc. Incineration of materials other than grain chaff and straw may not use the energy available in the most appropriate manner and all nitrogen is lost.

Advantages of incineration include:

- efficient energy extraction * up to 80 percent volume decrease * heat produced is easily utilized * low capital investment

Disadvantages include:

- good aeration is necessary * burned residue is of little value * labor intensive * nitrogen is destroyed.

Culturally, incineration is usually easily incorporated. Positive demonstration of viability is important as with most new technologies. Incineration is one recycling method that has proved to be economical in most situations. From simple, open fire burning to furnace incineration, this technology is efficient and easily understood.

III. SUMMARY

Agricultural waste recycling is of great importance in the world today. Recycled agricultural waste represents a valuable resource. Agricultural waste may be utilized through many methods of recycling.

A general overview of theory has been presented in this paper. Several methods of recycling have been discussed and general guidelines set forth. It is hoped that this information will provide the basis for particular waste recycling projects.

The possibilities of waste recycling are endless. It is left to the individuals responsible in particular situations to be innovative and apply the knowledge presented herein to the continuing and difficult task of returning a great resource to its place.

IV. BIBLIOGRAPHY

Barreveld, W. "Availability of Organic Residues as a Rural Resource." Proceedings of Bioconversion of Organic Residues for Rural Communities. Tokyo, Japan: United Nations University, 1979.

Bewick, M.W.M. Handbook of Organic Waste Conversion. New York, N.Y.: Nostrand Reinhold Co., 1980. 418 pp.

Bruttini, A. Use of Waste Materials. Westminster, England: P.S. King and Son, Ltd., 1923. 367 pp.

Cox, G.W. and Atkins, M.D. Agricultural Ecology. San Francisco, CA: W.H. Freeman and Co., 1979. 721 pp.

Midwest Plan Service. Livestock Waste Facilities Handbook. [City?], Iowa: Midwest Plan Service, 1975. 94 pp.

Palz, W., and Chartier, P. Energy From Biomass in Europe. Essex, England: Applied Science Publishers Ltd., 1980. 234 pp.

Pequegnat, C., ed. "Waste Recycling and Canadian Agriculture." Proceedings on Commercial Uses of Wastes and Animal Feed. Ottawa, Canada: Agricultural Economics Research Council of Canada, 1975. 253 pp.

van der Wal, P. "Perspectives on Bioconversion of Organic Residues for Rural Communities." Proceedings of Bioconversion of Organic Residues for Rural Communities. Tokyo, Japan: United Nations University, 1979.