Originally prepared from proceedings of a meeting of experts convened in December 1982 by Volunteers in Technical Assistance (VITA)

Revised May 1985

Published by: VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pro-info@vita.org

ISBN 0-86619-229-8

(c) 1985, Volunteers in Technical Assistance CONTENTS

Acknowledgements

Introduction

Water Boiling Test

Equipment Procedure Procedural Notes Data and Calculation Form Test Series Reporting Form

Controlled Cooking Test

Equipment Procedure Procedural Notes Data and Calculation Form Test Series Reporting Form

Kitchen Performance Test

Equipment Procedure Procedural Notes Data and Calculation Form Test Series Reporting Form

Technical Notes

Glossary

Abbreviations

APPENDIXES:

A. Concepts of Efficiency

B. Participants at Arlington meeting

C. Participants at Louvain "Woodstoves Seminar"

D. Participants at Marseille meeting

ACKNOWLEDGEMENTS

This document is a revision of Testing the Efficiency of Woodburning Cookstoves, first published by Volunteers In Technical Assistance in December, 1982. The earlier work was the outcome of a special international workshop held in Arlington, Virginia, through the support of the U.S. Agency for International Development (USAID), the Government of The Netherlands, and IBM/Europe. Since publication, many useful comments have been received from users of this document, enabling us now to clarify a number of concepts and remove certain inconsistencies. In some cases we have rejected suggestions that would have demanded a revision of fundamental principles agreed to at Arlington. Such changes were felt to go beyond the scope of this work.

These revised guidelines are an effort to bring the work of the Arlington Group to a wider audience for practice, scrutiny and further discussion. We hope that such a process will lead to an even more refined version of procedures for testing woodburning cookstoves.

Paul Bussman, The Woodburning Stove Group, Eindhoven, The Netherlands

Jonathon Loose, Intermediate Technology Development Group, Reading, England

K. Krishna Prasad, The Woodburning Stove Group, Eindhoven, The Netherlands

Timothy Wood, Volunteers in Technical Assistance, Arlington, Virginia, USA

February, 1985

INTRODUCTION

Testing is an essential component of any program that promotes the use of improved woodburning stoves in developing countries. This is true regardless of how programs are administered or by what means the stoves are disseminated.

Stove testing is the systematic measuring of the advantages and limitations of a particular stove model. Its primary aim is to help identify the most effective and desirable stoves for a specific social and economic context. With ongoing stove production, a testing program provides essential quality control and may lead to important design modifications.

Problems surrounding woodstove design and testing have gained increasing attention over the past several years. Many individuals and groups have become involved, circulating papers, and meeting occasionally to discuss problems. At the "Seventh Woodstove Seminar" held at Louvain, Belgium, March 4 - 5, 1982, it was agreed that a systematic effort should be undertaken to reach as wide a consensus as possible on field testing of woodstoves. Too many approaches to testing were being used, it was felt, resulting in misunderstanding and hindering comparison of results.

An informal international working group of Louvain participants and others on developing a standard for field testing of woodstoves met in Marseille 12 - 14 May, 1982. This group agreed that there was an urgent need for an internationally acceptable standard. It noted that field testing had been done in many places by many different people, some of whom have published on the subject and made suggestions for standards. None of the published suggestions was used as a basis for discussion. Rather, the group brainstormed from comments received following the Louvain meeting, and from new ideas, keeping the earlier suggestions in mind.

The consensus at Marseille was that:

* A worldwide standard should be simple and limited. A standard will be more acceptable if it imposes strict rules only where necessary, but includes recommendations where possible.

* A distinction should be made between testing done for local use only (for stove users and others) and testing where the results are intended to be transmitted to other places.

* The standard should represent a compromise between the widest possible range of applications, and the closest possible fit with actual cooking practices.

* It would be useful for the standard to classify the many different parameters that influence stove performance.

The Marseille group decided that evaluation concepts and reporting specifications could be fixed in the standard test procedure, and that food, fuels, and pots could be specified in local standards. While the stove itself cannot be standardized, a detailed description of the stove is needed with the test report. It was thought that an international standard might recommend a way to do this. Discussions resulted in a set of "instructions" for the draft of a proposed standard. The Marseille group draft was circulated among participants, who then provided comments. The resulting second draft was discussed, among others, at the meeting convened by VITA December 6 - 10, 1982.

The 13 stove experts from ten countries who attended the week-long Arlington meeting agreed on three basic tests and reporting procedures. By imposing a scientific standard in stove testing, the Arlington group hopes to assure a high degree of uniformity in stove test results from around the world. The widespread use of standardized testing procedures will permit the comparison of stove designs on a more systematic basis, and foster wider sharing of the results of research and development efforts. This will benefit stove designers and users, and ultimately all who depend on the world's forest resources.

The following tests were formulated by the group at Arlington:

A Water boiling test, to measure how much wood is used to boil water under fixed conditions. This is a laboratory test, to be done both at full heat and at a lower "simmering" level to replicate the two most common cooking tasks. While it does not necessarily correlate to actual stove performance when cooking food, it facilitates the comparison of stoves under controlled conditions with relatively few cultural variables. A Kitchen performance test, to measure how much fuelwood is used per person in actual households when cooking with a traditional stove, and when using an experimental Stove. The tester simply measures how much wood the family has at the beginning and at the end of each testing period.

A controlled cooking test, to serve as a bridge between the water boiling test and the kitchen performance tests. Trained local cooks prepare pre-determined meals in a specified way, using both traditional and experimental stoves.

The Arlington group recognized that some of the procedures described here differ significantly from what had been recommended in the past. The main difference is in the concept of efficiency used. These standards are based on a broader description and justification of efficiency than Percentage of Heat Utilized (PHU). They interpret evaporation as a measure of energy wasted, not energy used (see Appendix A, Concepts of Efficiency). It is not the group's intention to demand that these standards be adopted. Rather, it is hoped that stove testers will use the standards and share their experience in using them. The purpose of developing standards for testing is to help technicians get the most reliable results from their tests, to consider sources of error, and to interpret test results reliably. These standards do not preclude the use of existing ways of testing; however, the group thinks that the new standards can yield more reliable, comparable results.

This document includes the step by step procedures for each of the standardized tests, followed by Procedural Notes that give specific suggestions for conducting the tests. The sample data and reporting forms included for each test are designed to simplify the recording of essential information. For easy reference, Technical Notes giving background information relevant to all three tests are printed on colored paper. A glossary and list of abbreviations are followed by a section discussing concepts of efficiency used in testing stoves.

The original document was prepared by Dr. Timothy Wood, with Prof. Guido de Lepeleire, Dr. Gautam Dutt, and Howard Geller. Editing was done by Margaret Crouch, with typesetting by Maria Garth. The Arlington meeting was made possible by the support of the U.S. Agency for International Development (USAID), the Government of the Netherlands, and IBM/Europe. USAID also funded this revised edition of the manual. A complete list of the participants in the Arlington meeting is included in the Appendix.

WATER BOILING TEST

The Water Boiling Test (WBT) is a relatively short, simple simulation of common cooking procedures. It measures the fuel consumed for a certain class of tasks. It is used for a quick comparison of the performance of different stoves.

Water Boiling Tests use water to simulate food; the standard quantity is two-thirds the full pan capacity.

The test includes "high power" and "low power" phases. The high power phase involves heating the standard quantity of water from the ambient temperature to boiling as rapidly as possible. (see Technical Note 1). The low power phase follows. The power is reduced to the lowest level needed to keep the water simmering over a one-hour period.

Each WBT should be repeated at least four times. Results may be averaged and analyzed statistically.

EQUIPMENT

* Stove * Pots without lids - see Procedural Note 1) * A balance accurate to 10 grams with a recommended capacity of 5 kg (Technical Note 2) * Locally dominant wood species, air dried (Technical Notes 3, 4), preferably pieces of uniform size * Water, within 2 [degrees] C of ambient temperature * Timing device * Mercury or digital thermometer for measuring temperatures up to 105 [degrees] C (Technical Note 6) * Device to measure/estimate the moisture content of wood (Technical Note 4) * Forms for recording data and calculations * Optional: wire tongs for handling hot charcoal and wood; insulated gloves.

PROCEDURE

- Determine and record moisture content for wood to be used in test. See Technical Notes 3 and 4, pp. (Note: this is generally done for a series of tests, rather than for each individual test.)

- Note and record the test conditions. Prepare a drawing of the pots and stove to be tested. (Note: in any test series be sure to use the same pots for all tests.) Include all relevant stove dimensions and show how the pots fit into the stove (Technical Note 9). Note climatic conditions (Technical Note 8).

- Weigh the empty, dry pots, and record this weight on the Data and Calculation Form. Fill each pot with water to 2/3 capacity and record the new weight.

- Take a quantity of wood not more than twice the estimated needed amount, weigh it, and record the weight on the Data and Calculation Form.

- Place a thermometer in each pot so that water temperature may be measured in the center, about 1 cm from the bottom. Record water temperatures and confirm that they vary no more than 2 [degrees] C from ambient.

- After a final check of preparations, light the fire as in Technical Note 10. Record the exact starting time. Throughout the following "high power" phase of the test, control the fire with the means commonly used locally to bring the first pot to a boil as rapidly as possible.

- Regularly record the following on the Data and Calculation Form:

* the water temperature in each pot; * the weight of any wood added to the fire; * any action taken to control the fire (dampers, blowing, etc.); and * the fire reaction (smoke, etc.).

- Record the time at which the water in the first pot comes to a full boil.

- At this time rapidly do the following:

* Remove all wood from the stove and knock off any charcoal. Weigh the wood, together with the unused wood from the previously weighed supply. * Weigh all charcoal separately (Procedural Note 2). * Record the water temperature from each pot. * Weigh each pot, with its water. * Return charcoal, burning wood, and pots to the stove to begin the "low power" phase of the test.

Record all measurements on the Data and Calculation Form.

With practice a single tester can complete this step within 2 to 4 minutes and move on to Step 10 without introducing significant error to the data. If, however, this interruption is judged too difficult or disruptive, an alternate procedure is suggested in Procedural Note 3.

- For the next 30 minutes maintain the fire at a level just sufficient to keep the water simmering. Use the least amount of wood possible, and avoid vigorous boiling. Continue to monitor all conditions noted in Step 7. If the temperature of the water in the first pot drops more than 5 [degrees] below boiling, the test must be considered invalid.

- Recover and weigh separately the charcoal and all remaining wood. Record the weights.

- Weigh each pot with its remaining water. Record the weight.

- Calculate the amount of wood consumed, the amount of water remaining, the test duration, the Specific Fuel Consumption, and, for multipot stoves, the Consumption Ratio (Procedural Note 5). Minimum and maximum power levels may also be calculated (Technical Note 11).

- Interpret test results (see Procedural Note 4), and fill out a Test Series Reporting Form.

PROCEDURAL NOTES

- Stove tests are often conducted with lidded pots to reduce the effect of drafts on evaporation rate from the pot. However, if the testing site is properly protected from drafts, lids should be left off, thus reducing the error caused by condensed water dripping from the lid back into the pot.

- With lightweight stove models, often the stove and its contents can be weighed together as a unit, and the weight of the empty stove subtracted later. It is not necessary to separate charcoal and ashes, since ash weight is usually insignificant.

- "High power" and "low power" tests may be conducted separately. The fire is extinguished at the end of Step 7, and the stove is allowed to cool. The entire test is then repeated in exactly the same way, except that the fire is reduced the moment the first pot comes to a boil. There is no interruption to weigh water or fuel as described in Steps 8-13.

The test is ended 30 minutes after boiling, and all measurements are recorded. The weight of the fuel used during the high power phase is subtracted from the total amount used in the low power phase. A separate or modified data sheet is needed for recording test results. Final calculations remain unchanged.

- It is important to know how to interpret the results of the WBT, and to remember that a low specific fuel consumption indicates a high efficiency. As efficiency declines, Specific Fuel Consumption (SFC) rises. It is possible to use WBT results to judge the suitability of a stove for various cooking tasks. For example, for high power cooking (rapid frying and boiling), a stove with the greatest high power efficiency might be best; for simmering, however, the best stove might be the one that shows low SFC for both high and low power. (See also Appendix A which explains concepts of efficiency.

- The Consumption Ratio may be useful when testing stoves that accommodate more than one pot. It expresses the amount of water evaporated from the main pot as a fraction of the total evaporated from all pots.

The consumption ratio is always less than 1.0. The lower its value, the lower the proportion of heat used by the main pot.

There are at least two ways in which the Consumption Ratio may be useful to the stove tester:

a) It serves as a check on consistent stove operation. With multipot stoves the user determines how heat from the fire is apportioned to the various pots. In a series of Water Boiling Tests it is essential that this be done in a consistent manner. By comparing the Consumption Ratios in a test series one can detect variations in stove operation.

b) It may help to show whether enough heat reaches all the pots to be useful for cooking.

As a rule, Consumption Ratio should not be used as a correction factor for comparison of multipot and singlepot stoves. Such comparisons are never valid in Water Boiling Tests because of the many interfering variables. WATER BOILING TEST DATA AND CALCULATION FORM(*)

Test Number_______________ Location_________________________________________

Date______________________ Test conditions__________________________________

Stove_____________________ Remarks___________________________________________

Tester____________________ __________________________________________________

END OF END OF INITIAL HIGH POWER LOW POWER MEASUREMENT PHASE PHASE Wood moisture content a) ____________ Dry weight of Pot #1 b) ____________ Dry weight of Pot #2 c) ____________ Weight of wood d) ____________kg j) ___________kg s) ____________kg Weight of charcoal k) ___________kg t) ____________kg Weight of Pot #1 with water e) ____________kg m) ___________kg u) ____________kg Weight of Pot #2 with water f) ____________kg n) ___________kg v) ____________kg Water temperature, Pot #1 g) ____________[degree] C p) ___________[degree] C w) ____________[degree] C Water temperature, Pot #2 h) [degree] C q) ___________[degree] C y) ____________[degree] C Time i) ____________ r) ___________ z) ____________

(Use the graph outline on reverse side to record changes in water temperature)

CALCULATIONS HIGH POWER PHASE LOW POWER PHASE

Wood consumed A) d-j = ______________ kg J) j-s = _________________ kg Charcoal remaining B) K = ________________ kg K) t-k = _________________ kg Equivalent dry wood consumed C) A/(1+a)-1.5 B = ____ kg L) J/(1+a)-1.5 K = _______ kg Water vaporized, Pot, #1 D) e-m = ______________ kg M) m-u = _________________ kg Water vaporized, Pot #2 E) f-n = ______________ kg N) n-v = _________________ kg Consumption ratio F) D/(D+E) = _____________ P) M/(M+N) = ________________ Specific fuel consumption G) C/D = _________________ Q) L/M = ____________________ Duration of test H) r-i = _________________ R) z-r = ____________________ Burning rate I) C/H = ____________kg/min S) L/R = ______________kg/min

Overall Specific Fuel Consumption (SFC): (C+L)/(D+M) = ____________

(*) This is an example of a form to be completed every time a test is run. It is easily modified for cases where high and high-low power phases are run independently.

TIME/TEMPERATURE PLOT - HIGH POWER PHASE

WATER BOILING TEST TEST SERIES REPORTING FORM

Organization conducting tests _________________________________________________ Mailing address ____________________________________________________________ Name of stove tested __________________________________________________________ Test numbers being reported ___________________ Test supervisor _______________

SUMMARY OF TEST CONDITIONS (draft protection, ambient temperature, etc.)

______________________________________________________________________________ _______________________________________________________________________________ _______________________________________________________________________________

FUELWOOD

SPECIES APPROX % TOTAL MOISTURE MEAN DIMENSIONS (Botanic name) (by weight) CONTENT _______________ __________ Kg _________ % _______________ _______________ __________ kg _________ % _______________ _______________ __________ kg _________ % _______________ _______________ __________ kg _________ % _______________

POTS USED

POT 1 POT 2 POT 3

Weight (empty, dry) ________ kg _________ kg _______ kg Maximum capacity ______ liters _______ liters ______ liters Diameter at rim ________ cm _________ cm _________ cm Composition ____________ ______________ _____________

SUMMARY OF TEST RESULTS

HIGH POWER PHASE LOW POWER PHASE

TEST BURNING RATE SFC BURNING RATE SFC OVERALL NO. (kg/min) (kg/min) SFC

1 _____________ ____ ____________ ____ _________

2 _____________ ____ ____________ ____ _________

3 _____________ ____ ____________ ____ _________

4 _____________ ____ ____________ ____ _________

5 _____________ ____ ____________ ____ _________

(Full description of stove on reverse side)

(*) This is an example of a form to summarize and report results from a series of water boiling tests. It is easily modified for cases where high and high-low power phases are run independently.

DESCRIPTION OF STOVE:

TOP VIEW PERSPECTIVE

CUTAWAY VIEW WITH POT(S) FRONT

DETAILS OF STOVE CONSTRUCTION _________________________________________________ _______________________________________________________________________________ _______________________________________________________________________________ _______________________________________________________________________________ _______________________________________________________________________________ _______________________________________________________________________________

CONTROLLED COOKING TEST

The Controlled Cooking Test is intermediate to the rather simple Water Boiling Test and the involved Kitchen Performance Test. It is intended to provide estimates of the fuel consumed by a set of specified cooking tasks.

Unlike the Water Boiling Tests with its rigidly fixed procedures, the Controlled Cooking Tests uses variable procedures depending on the types of meals cooked, the stove design, and the manner in which the stove is used. Results of Controlled Cooking Tests are comparable only when conducted in the same series using exactly the same procedures and conditions.

The primary objectives of the Controlled Cooking Test (CCT) are:

* To compare the fuel consumed and the time spent in cooking a meal on different stoves; and

* To determine whether a stove can effectively cook the range of meals normally prepared in the area where it is intended to be introduced.

The Controlled Cooking Test may also be used:

* To compare different cooking practices on the same stove,,

* To give a cook the opportunity to learn how to use the stove; and

* To follow the Water Boiling Test in subjecting a stove to more realistic, but controlled, conditions.

The CCT is normally conducted in a laboratory or field demonstration center by trained stove testers with extension workers or potential users. The cook should be experienced in preparing traditional meals.

EQUIPMENT

* A homogeneous mix of fuelwood as it is normally available locally, sufficient for the required number of tests (see Technical Note 5).

* A selected type and amount of food sufficient for the required number of tests.

* Weighing instrument accurate to 10 grams, with a recommended capacity of 5 to 10 kg, depending on the amount of food prepared in each test (Technical Note 2).

* Timing device.

* The same pots, lids, and other cooking utensils to be used throughout the test.

* Forms for recording data and calculations.

* Optional: wire tongs for handling hot charcoal and wood; insulated gloves.

PROCEDURE

- Establish a test design that accurately represents common local cooking procedures. (Procedural Note 1). It is advisable to test both new and traditional stoves simultaneously under the same weather conditions and using wood of similar quality and condition.

- Remove any charcoal and ash from the stove to be tested. The stove should not be warm from a previous fire.

- Record climatic conditions (Technical Note 8).

- Take a quantity of wood not more than twice the estimated amount needed measure moisture content (Technical Notes 3, 4). Weigh it and record the weight on the Data and Calculation Form.

- Weigh the pots with their lids (if lids are normally used) and record the weight.

- Assemble, prepare and weigh the food to be cooked.

- Light the fire and record the time (Technical Note 10).

- Perform the defined cooking task.

- When the cooking task is completed, record the time (Procedural Note 2).

- Weigh separately the remaining wood and charcoal.

- Weigh the food in its pots, including any lids.

- Record comments from the cook on any problems encountered during the test, including qualitative differences between the tested stove and other stoves.

- Repeat the same test at least three times for each type of meal cooked. More tests may be required if there is much variation in the results.

- For each test calculate total test time and Specific Fuel Consumption. Then write a test report for each test using, if desired, the sample Data and Calculation Form on the following page. Include a description of:

* stoves and pots used in the test (Technical Note 9); * standard meal used in the test; and * standard procedure used to cook the meal.

PROCEDURAL NOTES

- The CCT design is tailored to specific local meals. It is therefore important to specify the following conditions:

* Pot types and sizes.

* Fuelwood types and sizes.

* One or two standard meals commonly prepared in the region. Where several types of meals are prepared, select no more than two for the test, one requiring long cooking time and the other short.

* Exact cooking tasks and sequences required to cook the standard meal. For example: "Bring the first pot to a boil; switch the first and second pots; bring the second pot to a boil; reduce the fire by breaking off charred ends of fuel; remove the first pot and simmer the second until the food is cooked."

Establishing the test design may be done in either of two ways: 1.) by conducting a thorough survey of local cooking practices to collect the needed information; 2.) by having a team of three to five experienced local cooks define the one or two standard meals and the specific way they should be prepared and cooked for the test.

- It is important to consider the criteria by which food will be considered "done," since this determines the time at which the tests will be finished. It is best to determine the time objectively, such as "The skins come off the beans," or "The porridge loses all traces of graininess." However, even if the criteria used are very subjective ("The sauce tastes right"), they should still be mentioned in the test design. Whatever the criteria used, the cook must be encouraged to be very consistent in judgement.

- Often the stove with its contents can be weighed together as a unit, and the weight of the empty stove subtracted later. It is not necessary to separate charcoal and ashes, since ash weight is usually insignificant. CONTROLLED COOKING TEST DATA AND CALCULATION FORM(*)

Test Number ______________ Location ___________________________________

Date _____________________ Test conditions ____________________________

Stove ____________________ Remarks ____________________________________

Cook _____________________ ____________________________________________

INITIAL FINAL BASIC TEST DATA MEASUREMENTS MEASUREMENTS

Weight of wood (A)________kg (G)________kg Weight of charcoal (H)________kg Wt of Pot 1 (empty) (B)________kg (I)________kg (with cooked food) Wt of Pot 2 (empty) (C)________kg (J)________kg (with cooked food) Wt of Pot 3 (empty) (D)________kg (K)________kg (with cooked food) Time (E)__________ (L)__________ Wood moisture content (F)__________

CALCULATIONS

(M) Weight of wood used A-G = _________kg (N) Equivalent dry wood used M/(1+F)-1.5 H = _________kg (P) Weight food cooked, Pot 1 I-B = _________kg (Q) Weight food cooked, Pot 2 J-C = _________kg (R) Weight food cooked, Pot 3 K-D = _________kg (S) Total weight food cooked P+Q+R = _________kg (T) Specific fuel consumption N/S = _________ (U) Total testing time L-E = ________min

Cook's comments about stove performance, ease of use, etc.: ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

(*) This is an example of a form to be used for each test that is run.

CONTROLLED COOKING TEST DATA AND CALCULATION FORM(*)

Test Number ______________ Location ___________________________________

Date _____________________ Test conditions ____________________________

Stove ____________________ Remarks ____________________________________

Cook _____________________ ____________________________________________

INITIAL FINAL BASIC TEST DATA MEASUREMENTS MEASUREMENTS

Weight of wood (A)________kg (G)________kg Weight of charcoal (H)________kg Wt of Pot 1 (empty) (B)________kg (I)________kg (with cooked food) Wt of Pot 2 (empty) (C)________kg (J)________kg (with cooked food) Wt of Pot 3 (empty) (D)________kg (K)________kg (with cooked food) Time (E)__________ (L)__________ Wood moisture content (F)__________

CALCULATIONS

(M) Weight of wood used A-G = _________kg (N) Equivalent dry wood used M/(1+F)-1.5 H = _________kg (P) Weight food cooked, Pot 1 I-B = _________kg (Q) Weight food cooked, Pot 2 J-C = _________kg (R) Weight food cooked, Pot 3 K-D = _________kg (S) Total weight food cooked P+Q+R = _________kg (T) Specific fuel consumption N/S = _________ (U) Total testing time L-E = ________min

Cook's comments about stove performance, ease of use, etc.: ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

(*) This is an example of a form to be used for each test that is run.

CCT Series Reporting Form (continued)

Defined procedures for cooking the meal. _____________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

Summary of cook's comments, Stove #1__________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

Summary of cook's comments, Stove #2__________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

KITCHEN PERFORMANCE TEST

The Kitchen Performance Test (KPT) measures the relative rate of fuelwood consumed by two stoves as they are used in the normal household environment. It is a prolonged test conducted with the willing cooperation of individual families. Compared to the previously described tests, the results of the KPT can provide the most reliable indication of stove performance under actual household conditions. However, because of the large effort involved, it is normally conducted only after the more controlled tests have been completed.

The primary objectives of the KPT are:

* To study the impact of a new stove on overall household energy use (Procedural Note 1); and

* To demonstrate to potential users the fuel-saving quality of a new stove in the household, and to specific correct operating practices.

Variations of the Kitchen Performance Test may also be used in conjunction with a stove dissemination program (Procedural Note 2) or as part of a survey of household energy use (Procedural Note 3).

Kitchen Performance Tests should be carried out by an investigator who is accustomed to following instructions, is motivated to do so, and has certain basic numerical skills.

EQUIPMENT

* Balance for weighing fuelwood. (Technical Note 2) * Forms for recording data and calculations * Pots, etc., to be supplied by household

PROCEDURE

- Select households to participate in the test (Procedural Note 4). Explain to family members the purpose of the test, and arrange to measure their fuelwood each day. Encourage the family to use only a single stove throughout the testing period.

- Gather any needed information about each participating household. For example: determine the sex and age of each person served meals, and use this information to calculate the number of standard adult persons served (Procedural Note 5); ask about the approximate cost of the fuelwood used, in terms of either money spent or time needed to collect it; and collect any other information that may help interpret the final data (Procedural Note 6).

- Define an inventory area for fuel consumption measurement. Any fuel entering or leaving this area must be accounted for (Procedural Note 7). Weigh all wood and other fuels in the inventory area. Estimate or measure the moisture content of the wood (Technical Note 4).

- Define the testing period of seven consecutive days. If it is not possible to measure for seven days, measure for at least five days. Stop and start at the same hour each day (Procedural Note 8).

- Visit the household at least daily, if possible, without being intrusive. Weigh wood remaining in the inventory area, and add to it if necessary. Inquire about the number of people being served each day, and confirm that the stove is operating properly.

- Compile the results at the end of eight days. Calculate specific daily consumption for each household, and then the mean and standard deviation (Technical Note 12). Compare the results with those from households using other stoves.

- Inform participating families of the results, and thank them for their cooperation.

PROCEDURAL NOTES

- The introduction of a new stove may alter the amount and type of cooking done in the household. For example, the result may be a substantial improvement in the well-being of the family, but make little change in overall fuel use. Or it may be that a fire enclosed within the stove provides so little light that it becomes necessary to use a kerosene lamp.

- It may be tempting to use the results of the KPT to estimate the fuel saving potential of a new stove before it is widely accepted and used. For this purpose, however, the test would have to be greatly expanded to include:

* many more households, carefully selected to be representative of the regional population;

* a period of time that includes all major seasons;

* a study of stove deterioration rates and repair records; and

* an economic analysis demonstrating the economic attractiveness of the stove to both the user and the producer.

- A survey of cooking practices to determine current local cooking procedures, foods cooked and eaten, types of stoves used, etc., is a useful starting point for the development and dissemination of improved cook stoves. The survey may be accompanied in a number of households by a measurement of all the fuel used for cooking, such as is involved in the Kitchen Performance Test.

Later, new stoves can be introduced into these same households, and another KPT may be carried out after the households have had an opportunity to get acquainted with the new stoves. At that time the KPT may be accompanied by a user survey to determine how well the stoves are being received, with later surveys to evaluate other parameters such as stove durability. Later KPTs may be performed to evaluate whether the fuel savings have remained the same and if other factors have had a positive or negative influence on the stove's long-term acceptability.

- For meaningful results:

* Households should be selected from approximately the same economic level. This will reduce variation and permit more reliable interpretation of the results.

* Participating families should use fuelwood for at least 90 percent of their household cooking needs.

* A minimum of five participating households is essential. Depending on the expected difference in fuel use between the two stoves tested, a larger number of households may be necessary.

- For purposes of this test, the "standard adult" will be defined according to a simplified version of the widely used League of Nations formula as shown in Table I. (Guidelines for Woodfuel Surveys, for F.A.O. by Keith Openshaw). TABLE I

"Standard adult" defined in terms of sex and age

Fraction of Sex and age standard adult

Child, 0-14 years 0.5 Female, over 14 years 0.8 Male, 15-59 years 1.0 Male, over 59 years 0.8

- Other information gathered for each family may include:

* the number and types of any other stoves used regularly (for making tea, heating water, cooking manioc, etc.);

* the major activity of the head of the household (a possible indication of family economic level);

* easily observable indicators of social or economic status;

* uses made of fuelwood other than for cooking food; and

* tribal or cultural affiliation.

- It is recommended that no more fuel be in the inventory area than is likely to be consumed during the one-week test period. If much more fuel is stored than will be used, define a smaller inventory area from which all fuel for the test is taken. Stress to household members that only wood from the small area be used during the test, and that if more wood is needed, the investigator should be present when it is added to the pile. The number of visits the investigator must make to the household to weigh the wood will depend on the size and adequacy of the initial inventory.

- The recommended seven-consecutive-day test period recognizes that many family activities are conducted according to a weekly routine. Seven days is the shortest time likely to include market days, work days, and any weekly religious observances in their proper proportion.

It often happens that the person conducting the test is unwilling to work on the day of weekly religious observance. In such a case, advance provision should be made for a substitute on that day, if possible.

Note that a seven-day test usually requires eight days of measurement (see Data and Calculation Reporting Form on the following page). Similarly, if only a five-day test is planned, measurements will be taken for six days.

- Different types and sizes of wood used by different households may introduce unwanted variation to test results. To avoid this, the tester may consider providing uniform fuelwood to be used for the duration of the test. It is important, however, that this practice not encourage the household to use significantly more or less wood than it would normally. KITCHEN PERFORMANCE TEST DATA AND CALCULATION FORM(*)

Household No. __________ Family Name __________________________________ Location _________________________________________________________________

HOUSEHOLD

STANDARD ADULT NUMBER EQUIVALENTS OTHER HOUSEHOLD INFORMATION

Children 0-14 years _______ x 0.5 = _________ ___________________________ Women over 14 years _______ x 0.8 = _________ ___________________________ Men aged 15-59 yrs. _______ x 1.0 = ____________________________________ Men over 59 years _______ x 0.8 = ____________________________________

(A) TOTAL ADULT EQUIVALENTS: ____________________________________

FUELWOOD

SPECIES APPROX. % TOTAL MEAN MEAN (Botanic name) (by weight) LENGTH DIAMETER ________________________________cm ______cm __________________ ________ ______cm ______cm ________________________________cm ______cm

Condition of fuelwood: (dry / damp / wet / green)_______________________ Fuelwood cost per kg: ________________________ OR ____________ = $_______ estimated collection time local currency US dollars

ALTERNATE FUELS/STOVES

DESCRIPTION FUNCTION Other fuels in use: ________________________ ___________________________ ________________________ ___________________________ Other stoves in use: ________________________ ___________________________ ________________________ ___________________________

TOTAL WOOD REMAINING WOOD ADDED TO IN INVENTORY AREA INVENTORY AREA COMMENTS

Day 0 (None) kg _________kg ______________________________ Day 1 _________kg _________kg ______________________________ Day 2 _________kg _________kg ______________________________ Day 3 _________kg _________kg ______________________________ Day 4 _________kg _________kg ______________________________ Day 5 _________kg _________kg ______________________________ Day 6 _________kg _________kg ______________________________ Day 7 (B) _________kg (None) kg _____________________________

(C) TOTAL WOOD ADDED TO INVENTORY: ________kg (D) TOTAL WOOD CONSUMED: C-B = ________kg (E) TEST DURATION: _____________ days SPECIFIC DAILY CONSUMPTION: D/(AxE) = ____________

(*) This is an example of a form to be used for each participating household.

KITCHEN PERFORMANCE TEST TEST SERIES REPORTING FORM(*)

Organization conducting tests ______________________________________________ Address Names of stoves compared: (1) ______________________ (2) __________________ Testing location ___________________________________________________________ Testing period ___________________________ Names of test supervisor ______ Name of test supervisor (months) (year)

STOVE #1 STANDARD ADULT SPECIFIC DAILY FUELWOOD EQUIVALENTS CONSUMPTION COST / KG

ARITHMETIC MEAN: ____________ ___________ _________ STANDARD DEVIATION: ____________ ___________ _________ COEFFICIENT OF VARIATION: ____________ ___________ _________ STANDARD ERROR ____________ ___________ _________ 95% CONFIDENCE INTERVAL: ____________ ___________ _________ STOVE #2

ARITHMETIC MEAN _____________ _____________ _________ STANDARD DEVIATION: _____________ _____________ _________ COEFFICIENT OF VARIATION: _____________ _____________ _________ STANDARD ERROR: _____________ _____________ _________ 95% CONFIDENCE INTERVAL: _____________ _____________ _________ (TOTAL NUMBER OF TESTS ________________)

Specific Daily Consumption: t-Value= _____ at ______ % level of confidence and ______ degrees of freedom.

(Attach a full description of both stove models tested)

(*) This is an example of a form used to summarize and report results from a series of tests of two stoves being compared.

TESTING PROCEDURES

- Atmospheric pressure and boiling temperature

The normal boiling temperature of water depends on atmospheric pressure, which is mainly a function of altitude above sea level. At an altitude ((H)) the normal boiling temperature can be computed from

[T.sub.b] = (100 - H/300) [degrees] C

when H is expressed in meters. For example, the normal boiling point is 100 [degrees] C at sea level, and 95 [degrees] C at 1500 m altitude.

When comparing high-power WBT results from different places this can be taken into account by using a simple temperature factor:

W" = W'([T.sub.b] - [T.sub.o])/100

where W" is the corrected amount of water processed, [W.sub.o] is the weighed quantity of water, and [T.sub.o] is the starting temperature. The reference temperature difference is considered to be 100 [degrees] C.

Note that cooking times increase with reduced boiling temperatures at high altitudes. The cooking time is doubled for a temperature decrease of 5 [degrees] to 10 [degrees] C, depending on the kind of food. This may influence Kitchen Performance Test results, but not Water Boiling Tests.

- Weight (mass)

Weighing can be done with any good balance that is accurate to a minimum 1 percent of the full-scale reading. For field testing, direct reading instruments are preferable, as no adjustments of weights are needed. Spring balances do a good job if they have a long reading scale and thus good resolution, and if they are used within 20 to 100 percent of the full capacity. Spring balances should occasionally be checked with calibrated weights (1 liter of water weighs 1 kg, etc.) A set of balances with different full-scale capacities should be used; for example, 1, 5, and 15 kg. Compare them with each other: they should give the same reading for the same load.

The weighing basket used with a balance should be as light as possible, since precision is lost when the difference between two weighings is relatively small.

- Moisture content of wood.

The available heating energy of fuelwood is directly influenced by its moisture content. This is usually expressed on the basis of dry wood, according to mass of moisture in wood sample Moisture content (x) = _______________________________ mass of oven-dry wood sample

Thus the heating value of moist wood, [H.sub.x], can be calculated from the heating value of oven-dry wood, [H.sub.o], by [H.sub.o] [H.sub.x] - _______ Ho [H.sub.x] - ________ (*) 1 + x

So-called "air-dried" wood is, in fact, moist. Its moisture content varies with the average relative humidity and with the species of wood.

For example, in saturated air (RH = 1), 1.0 kg of dry wood will contain about 0.2 kg of water (possibly more). At a lower RH = 0.6, the moisture content X drops to about 0.12. Of course, RH and X can be expressed as percentages as well.

As a consequence, a larger quantity of moist wood [M.sub.x] is needed for a given job than of dry wood [M.sub.o]. This can be accounted for by computing an equivalent dry wood consumption from a measured moist wood quantity.

(equiv. dry wood) [M.sub.o] = (1 - X) . [M.sub.x] (moist wood)

(*) This is an approximate formula. For a more exact formula, see K. Krishna Prasad, "Wood-burning Stoves: Their Technology, Economics, and Deployment," Working Paper for World Employment Programme Research, International Labour Organization, Geneva, 1983.

- Moisture measurements

The moisture content (X) of air-dried firewood can be estimated from the humidity RH (See Technical Note 3) (X = 0.2 RH).

The most direct and precise procedure is to make a double weighing of a moist or air-dried sample: first as it is, and then after drying it in an oven (at 110 [degrees] C for 24 hours or more, depending on the sample size). With [M.sub.x] (moist weight) and [M.sub.o] (dry weight):

The precise weight of the wood sample can be recorded periodically. When there is no change in two successive weighings the sample is presumed to be oven-dry and its new weight, [M.sub.x], is recorded. The moisture content of the original sample is then given by

X = ([M.sub.x] - [M.sub.o]/[M.sub.o]

where [M.sub.x] is moist weight and [M.sub.o] is oven-dry weight.

When a commercial drying oven is not available, it is possible to construct a simple substitute using electric light bulbs. For a description, see the article by Bill Stewart in Boiling Point, published by Intermediate Technology Development Group, April 1984.

An alternative method to determine moisture content is by use of a battery-powered moisture meter. These devices work on the principle that electrical conductivity of the wood varies with its moisture content. The results depend slightly on the species of wood and the quality of the instrument used. Generally they detect as little as X < 0.3.

- Fuelwood variation

Different types, sizes, and conditions of fuelwood are a potential source of great variation in all the tests presented here. The following precautions can help minimize this variation:

* Use only wood that has been thoroughly air dried. For sticks 3 to 4 cm in diameter drying time may be 3 to 8 months, depending on temperature, relative humidity, degree of protection from rain and mists, amount of air circulating through the wood pile, and wood species. Hot water and steam escaping from the wood as it is burned are indications of very moist wood.

* Wood may be cut in a uniform size (3 x 3 cm, for example) and only this wood used for stove testing. While this gives uniformity, it is often difficult to ignite and maintain a fire without smaller or tapered pieces.

Alternatively, if a series of tests is planned, prepare in advance a stack of fuelwood to be used for each test. Stacks should be as similar as possible in terms of wood type and size. They should then be bound tightly to prevent loss of any pieces. Sealing each wood stack in a large plastic bag will protect the wood from outside moisture.

- Temperature

Mercury thermometer are, in general, precise but breakable. The glass can break, and the liquid column can separate as well. Spare glass thermometers should be kept on hand. Metallic thermometers are more resistant but need periodic calibration, for example, by comparison with a good quality glass thermometer. Rechargeable battery-operated thermistors and thermocouples have proven very useful in field work, although models with digital readouts that are indistinct in direct sunlight should be avoided. In any case, look for instruments with a long scale, as they give better resolution and precision.

Before using a thermometer for stove testing, check it in visibly boiling water and look for a possible difference between the reading and the normal boiling point for that altitude:

altitude (meters) Actual boiling point = 100 - _________________ 300

For Water Boiling Tests, simmering means that the water temperature is kept no lower than 5 [degrees] C below the actual boiling temperature. If water temperature does drop below this point, the test should be discontinued.

- Volume

Volumes can be measured with graduated bottles. One can also use commercial bottles with known volumes (1/4, 1/3, 3/4, 1/1 liter). A balance can do the job, too, as 1 liter of water weighs 1 kg.

- Climatic conditions

Among the climatic data to be reported during stove testing, the most important are: air temperature, wind conditions, and relative humidity.

* Air temperatures affects the rate of heat loss from stove and pots. It is also establishes initial water temperature in the Water Boiling Test. Ideally, air temperature measurements should be taken before and after each test so that a mean value can be estimated.

* Wind conditions affect the stove's draft and can have considerable influence on stove performance. Ideally, stove testing should be done only when conditions are calm. Where this is not possible, a windbreak should be erected around the stove to reduce air movement.

* Relative humidity provides one indication of the moisture content of air-dried firewood (see Technical Note 3). It is simple and useful condition to measure during stove testing. For this purpose, a small sling psychrometer, a hair hygrometer, or a similar instrument is satisfactory. Recalibrate a hygrometer frequently by wrapping it in a wet cloth, leaving it for five minutes, and adjusting it to 100 percent RH.

- Pot and stove description

The test results are determined largely by dimensional relations between the stove and the pot. The internal dimensions of the stove are especially important. Therefore:

* Give a complete pot description (size, shape, weight, capacity, material, etc.).

* Give a functional stove description (inside dimensions, total weight, wall thickness, etc.). Sketches should show at least the top view, cutaway side view with placement of pots, and a perspective. Drawings should be clearly labeled and all dimensions should be marked.

- Ignition

For Water Boiling Tests and Controlled Cooking Tests it is important to light the fire in the way it is normally done in the households of the area. For example, if kerosene (paraffin) is used as the ignition material, three pieces of wood can be dipped vertically into kerosene (about 8 cm deep) for about five seconds, and the excess kerosene tapped off. The kerosene-dipped wood should contain about 10 grams of kerosene (check it by weighing the wood before and after dipping). Or, a measured amount of kerosene (less than 10 grams) may simply be poured over the wood. The test's starting time coincides with the lighting of the kerosene-soaked wood pieces. If desired, the kerosene used may be considered as consumed fuel (1 gram of kerosene is equivalent to about 2 grams of wood); however, the energy involved is so small that it may safely be ignored in the calculations.

- Calculation of power

Power refers to the rate at which energy is used. It may be expressed as the amount of fuel used per unit of time (for example, 3 kg wood/hour, or 50 grams/minute). A widely used unit of power is the watt, defined as one joule of energy per second. (one gram of air-dry wood yields about 20 joules).

Therefore, if a stoves consumes 300 grams of wood in 5 minutes you may calculate the power level during that time as follows:

300 x 20 joules 6000 joules ______________ = ___________ = 20 joules/sec = 20 watts

5 x 60 seconds 300 seconds

- Statistical Analysis of Test Results

Any set of tests yields many measurements of a few well-defined parameters. To get the maximum amount of information and insight about the system being tested, it is useful to make a few relatively simple statistical calculations. In principle, these can be carried out on all the tests described in these guidelines. In practice, the Water Boiling Tests and the Controlled Cooking Tests can be expected to be performed under laboratory-like conditions by technically trained personnel. Variations in test results can generally be attributed to either a faulty test design or deliberate changes introduced by the tester on the system or its operating conditions. Thus analysis of results is simple. However, the Kitchen Performance Test contains several variables that are not under the control of the test designer enter into the picture. This is the place where the statistical analysis becomes vital. GLOSSARY

CONSUMPTION RATIO: An expression sometimes used in the WBT with multipot stoves. It describes the amount of water evaporated from the first pot relative to the water evaporated from all the pots on the stove and is calculated by CR = [W.sub.1]/([W.sub.1] + [W.sub.2] + [W.sub.3] + ... + [W.sub.n]), where W is the amount of water evaporated.

CONTROLLED COOKING TEST (CCT): An intermediate laboratory test to compare fuel and time used to prepare a meal on different stoves, and to determine the range of meals a stove can accommodate in a given area. See page 11.

HIGH POWER: Maximum stove power. WBT high power phase brings the water to boiling as rapidly as possible, and then maintains boiling at the same heat level for 15 minutes. See page 1.

KITCHEN PERFORMANCE TEST (KPT): A field test to measure fuel consumption in a normal household situation. See page 19.

LOW POWER: Minimum stove power. WBT low power phase requires the fire to be maintained at the lowest level necessary to simmer water for one hour. See page 1.

SPECIFIC FUEL CONSUMPTION (SFC): An expression of the total amount of food or water in the CCT or wet, divided by the total amount of wood used to cook it. See the Data and Calculation form on pages 7 and 15.

SPECIFIC DAILY CONSUMPTION (SDC): An expression used in the KPT to describe the amount of fuelwood (in kg) used for cooking per person served per day. See the KPT Data and Calculation Form on page 25.

STANDARD ADULT EQUIVALENT: A standard way to define and compare the number of people in a family group. See Table I, page 22.

WATER BOILING TEST (WBT): A simple laboratory test to measure the fuel and time necessary to cook a simulated meal. See page 1.

ABBREVIATIONS

C Celsius

CCT Controlled Cooking Test

cm centimeter

ISO International Standards Organization

kg kilogram

KPT Kitchen Performance Test

kW kilowatt

RH relative humidity

SDC Specific Day Consumption

SFC Specific Fuel Consumption

WBT Water Boiling Test

APPENDIXES

A. Concepts of Efficiency

B. Participants at Arlington Meeting

C. Participants at Louvain "Woodstoves Seminar"

D. Participants at Marseille Meeting

Appendix A

CONCEPTS OF EFFICIENCY

There are many different ways of looking at stove performance and of measuring stove efficiency. A widely used method compares the energy that goes into the stove with the energy that comes out, to determine Percentage of Heat Utilized (PHU). A broader concept of efficiency accounts for energy losses in evaporation. Once food reaches the boiling point, the amount of additional heat it absorbs is relatively small. In water-based cooking the pot requires only enough heat to maintain boiling temperatures--all else is excess. This excess heat is used to generate steam, which escapes from the pot without adding anything to the cooked food. Thus a stove that is regulated to maintain simmering temperature with at least production of steam is, in that respect, most efficient. This section will review some different ways of measuring

- Energy losses

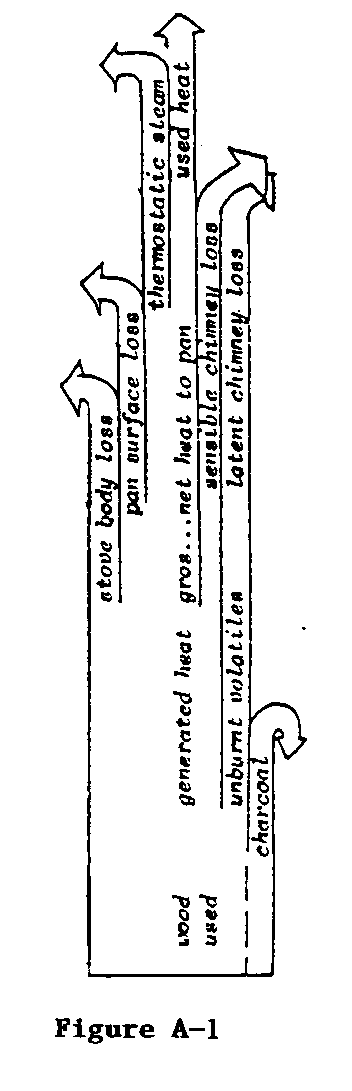

Figure 6 is an energy flow diagram for a woodburning

cook stove. Useful heat is absorbed in the food, but heat losses are associated with: - incomplete combustion of wood - heat loss from the stove body to the environment - heat loss from the pot surfaces (including lids) - heat loss through the chimney - thermostatic steam escaping from the pot due to excessive stove power.

- Partial efficiencies

Different partial efficiencies can be suggested, for example:

* combustion efficiency heat generated by combustion [n.sub.c] = ____________________________ - energy potential in fuelwood

- heat transfer efficiency

gross heat input to the pan [n.sub.t] = ___________________________ heat generated

<FIGURE A-1>

* pot efficiency

[n.sub.p] = net heat input to pot = gross heat input - surface losses _____________________ _________________________________ gross heat input gross heat input

* control efficiency

[n.sub.r] = heat absorbed by the food _________________________ net heat input to the pot

These efficiencies can be associated with stoves operated in predictable or well-defined ways, such as at a single power level, or in defined cooking patterns.

- Overall efficiency

An "overall stove efficiency" is often used. This is a product of the first three partial efficiencies described above. n' = net heat input to pot ____________________________ = [n.sub.c] . [n.sub.t] . [n.sub.p] energy potential in fuelwood A cooking efficiency can be defined as:

* [n.sub.c] = heat absorbed by the food ____________________________ energy potential in fuelwood

This final efficiency level accounts for all the heat losses. It is the overall stove efficiency multiplied by control efficiency:

n = [n.sub.c] . [n.sub.t . [n.sub.p] . [n.sub.r] = n' . [n.sub.r]

- Specific consumption

Alternatively, stove performance can be expressed by specific consumption figures instead of efficiencies. For example, at the cooking efficiency level:

mass of consumed fuelwood SC = _________________________ mass of cooked food

There is a link with the cooking efficiency, as

heat absorbed in cooked food n = ____________________________ energy potential in fuelwood n = (mass of cooked food) . c . [delta] t _______________________________________ (mass of consumed wood) x heating va]ue 1 c . [delta] t Thus: n = ___ _____________ SC heating value

when c represents the weighted-mean specific heat of the food (4.184 kJ/kg), and [delta][t the temperature change (from ambient temperature to boiling temperature). 1 c t SC = _____________ n heating value

- Efficiencies in Water Boiling Tests

The overall stove efficiency can be measured in Water Boiling Tests by heating the stove at high power, or by heating it at a controlled power level where steam generation simulates absorbed heat. A power-efficiency plot can be drawn, with power limits [P.sub.min] - [P.sub.max].

Cooking efficiency can be measured in a similar way. Note that in this case the steam generation is a loss. At simmering power levels the cooking efficiency is close to zero. The cooking efficiency concept therefore has been applied to a cycle that includes both the heating up period and simmering. In this case, however, the cooking efficiency drops as simmering times increase.

A better approach to this problem is to switch to specific consumption concepts: 1 c. [delta] t = [delta] t . c SC = __ ____________ _________ ___ n H.V. n H.V.

When the efficiency goes to zero during simmering, the SC figure will not go to infinity (which is meaningless). The reason for this is that the temperature change [delta]t is also zero.

For practical reasons a Water Boiling Test report should give not only the specific fuel consumption, but the power limits and evaporation as well. This will make it easier to predict cooking test results from simple Water Boiling Tests.

Cooking efficiencies can more realistically be checked in Controlled Cooking Tests. Again, the concept should be applied to the entire cooking cycle. Note, however, that for the Controlled Cooking Test the specific consumption is very dependent on the meal cooked, and can only be used to compare two stoves that have cooked the same standard meal.

Table A-1 summarizes WBT data, and shows how data from WBT can be used to judge stove performance in actual cooking tests. The procedure indicated is valid only for one-pot-hole stoves. At the top of the table are the WBT data from two different stove models. Below that the WBT data are applied to two imaginary cooking situations. In the first test, 4 kg of food is heated to boiling, and then simmered for 90 minutes. The second test is the same except that the food is simmered only 15 minutes.

The quantity of food to be cooked is expressed as

W' = 4 kg

The expected water evaporation [W.sub.e] is computed from the evaporation rate in the WBT, and the duration of the cooking test. The initial food and water used is

W' + [W.sub.e] = W

The time to boil is expected to be roughly proportional to the initial food and water

initial food and water (CCT) [(time to boil).sub.cooking] = [(time to boil).sub.wbt] X ____________________________ initial water (WBT)

* The expected wood consumption is the sum of - wood to boil: burning rate at [P.sub.max] x time to boil - wood to simmer: burning rate at [P.sub.min] x simmer time * The expected specific consumption derives from

wood to boil + wood to simmer SC = _____________________________ water vaporized, pot #1

The above approach gives an estimate--not a guarantee. Wood consumption might be higher than shown due to limited dynamic flexibility, poor stove control, or other reasons.

Table A-1

Using Water Boiling Test results to calculate expected stove performance in a Controlled Cooking Test.

WBT data: Stove 1 Stove 2

Power P 2 - 4 kW 1 - 4 kW (0.4 - 0.8 kg/h) (0.2 - 0.8 kg/h) Flexibility (Pmax/Pmin 2 kW 3 kW Initial water W' 5 kg 5kg Water left W' 4.05 kg 4.68 kg Evaporation We 0.95 kg/h 0.32 kg/h Time to boil [t.sub.b] 20 min. 30 min. [SSC.sub.1] 0.055 0.080 [SSC.sub.2] 0.167 0.127

Cooking Test 1

(4 kg x 90 min simmer) Cooked food W' 4 kg 4 kg Evaporated water We 0.95x90/60 = 1.43 kg 0.32x90/60 = 0.48 Initial food and water W 5.43 kg 4.48 kg

Time to boil [t.sub.b] 5.43/5kgx20min = 22min 4.48/5x30 = 27 min Wood: to heat (kg) (22/60)x0.8kg/h = 0.293 (27/60)x0.8kg/h = 0.360 Wood: to simmer (kg) (90/60)x0.4kg/h = 0.600 (90/60)x0.2kg/h = 0.300

0.893 0.660 Specific consumption 0.224 0.165

Cooking Test 2

(4 kg x 90 min simmer) Cooked food W' 4 kg 4 kg Evaporated water [W.sub.e] 0.95x90/60 = 1.43 kg 0.32x90/60 = 0.48 Initial food and water W 4.236 kg 4.08 kg

Time to boil [t.sub.b] 4.236/5x20 = 17 min 4.08/5x30 = 24.5 min Wood: to heat (kg) (17/60)x0.8kg/h = 0.225 (24.5/6)x0.8kg/h = 0.327 Wood: to simmer (kg) (15/60)x0.4kh/h = 0.100 (15/60)x0.2kg/h = 0.050

0.325 0.377 Specific consumption 0.081 0.094

APPENDIX B

Participants at Arlington Meeting

Dr. Samuel Baldwin Mr. Hamata Ag Hantafaye CILSS/VITA Laboratoire d'Energie Solaire B.P. 3826 B.P. 134 Ouagadougou, Upper Volta Bamako, Mali

Prof. dr. ir. G. de Lepeleire Mr. Stephen Joseph Laboratorium voor Koeltechnik Intermediate Technology Development en Klimaatregeling Group Katholieke Universiteit 9 King Street Leuven Celestijnenlaan 300 London WC2E 8HN 3030 Heverlee, Belgium United Kingdom

Dr. Dhammika de Silva Ms. Karen Kennedy Wood and Cellulose Section Aprovecho Institute Ceylon Institute for 442 Monroe Street Scientific and Industrial Eugene, Oregon 97402 USA Research P.O. Box 787 Prof. dr. K. Krishna Prasad 363 Bauddhaloka Mawatha University of Technology, W&S Colombo 7, Sri Lanka P.O. Box 513 5600 MB Eindhoven, The Netherlands Dr. Gautam S. Dutt Center for Energy and Ing. Marco Augusto Recinos Environmental Studies Proyecto Le a Princeton, NJ 08544 USA ICAITI Apartado Postal 1552 Mr. Howard Geller Avenida 1a Reforma 4-47, Zona 10 American Council for an Guatemala, Guatemala, C.A. Energy-Efficient Economy 1001 Connecticut Ave., N.W. Mr. Sylvain Strasfogel Suite 530 Association Bois de Feu/GRET Washington, DC 20036 USA 73, Avenue Corot 13013 Marseille, France Dr. C.L. Gupta TERI Field Research Unit Dr. Timothy S. Wood c/o Sri Aurobindo Ashram VITA Pondicherry 605002 India 1815 North Lynn Street Suite 200 P.O. Box 12438 Arlington, Virginia 22209-8438 USA

APPENDIX C

Participants at Louvain "Woodstoves Seminar"

- Michel Christiaens - G. de Lepeleire Laboratorium voor Koeltechniek en Klimaatregeling Katholieke Universiteit Leuven (Louvain) Celestijnenlaan 300A B-3030 Heverlee, Belgium Tel.: 016-23.49.31

- Beatrix Westhoff - Franz Zinner Sozietat fur Enwicklungsplanung (SFE) Friedrichstrasse 38 D-6000 Frankfurt am Main 1, West Germany

- Van der Spek Alexander

- P. Bussman

- K. Krishna Prasad

- Vermeer Nord-Jan

- C. Nieuwelt

- M. O. Sielcken

- P. Verhaart

- P. Visser

- P.T. Smulders

- S.F. Laperre

- N. Eossche Technische Hogeschool Eindhoven (THE) Postbus 513 5600 MB Eindhoven, The Netherlands Tel: 47.38.30/47.21.47

- D.L.M. Baay - Eric Ferguson - W.F. Sulilatu TON/MT Postbus 342 7300 AH Apeldoorn, The Netherlands

- Robert Celaire GRET/GERES, 34 rue Dumont d'Urville, 75116 Paris France Tel: 502.10.10 Centre St. Jer me 13397 Marseille Cedex 13, France Tel: 98.90.10, ext 367, code 264

- P. Dunn Department of Mechanical Engineering University of Reading Whiteknights Reading RG6 2AH, United Kingdom

- H.E. Huynink Populierendreef 257 2272 RE Voorburg The Netherlands

- Yvonne Shanahan - Stephen Joseph ITDG Power Unit A.R.S. Shinfield University of Reading Whiteknights Reading RG6 2AH, United Kingdom

- Waclaw L. Micuta Bellerive Foundation 5, rue du Vidollet CH-1202 Geneva, Switzerland Telex: 427993, tel: (22)33.74.22

- Rainer Geppert - Cornelia Sepp GTZ GmbH Deutsche Gesellschaft fur Technische Zusammenarbeit Postfach 5180 Dag-Hammerskjoldweg 1 D-6236 Eschborn 1, West Germany

- Peter Pluschke GATE (German Appropriate Technology Exchange) Postfach 5180 D-6236 Eschborn 1, West Germany

- Gunter Salzmann Friedrichstrasse 38 D-6000 Frankfurt/Main

- Ianto Evans Aprovecho Institute 442 Monroe Street Eugene, Oregon 97402 USA Tel: 503/683-2776

- Robert Chom - Anne Spirlet - Michel Taymans Agence Internationale du D veloppement Rural (AIDR) Handelsstraat 20 B-1040 Brussels, Belgium

- Alice Guidicelli CEE-D veloppement/Energie Berlament 995 B-1049 Brussels, Belgium Tel: 02/735.00.40, ext. 3771

- J.A. Boer Ministry Foreign Affairs Muzensstraat 30 The Hague, The Netherlands

- Dr. Timothy Wood VITA 1815 North Lynn Street, Suite 200 P.O. BOx 12438 Arlington, Virginia 22209-8438 USA Tel: (703) 276-1800

- Bernard Kauffmann GRDPR 145, rue St. Dominique 75007 Paris, France Tel: 705.16.29

- Louis Vroonen ABGS (Ministry of Developing Countries) Maraveldplein 5 1050 Brussels, Belgium

- Sylvain Strasfogel Association Bois de Feu/GRET 73, avenue Corot 13013 Marseille, France Tel: (91) 70.92.93

- J.B. Roggeman Club du Sahel 13-15 Chaus e de la Muette 75016 Paris, France

- Vera Van Eenoo Zeeptstraat 50 B-2850 Keerbergen, Belgium

- Donaat Cosaert - Chris Avondts ATOL Plijde Inkomststrzat 9 B-3000 Louvain, Belgium

- Luc Vandaele Werkgroep Zachte Technologie St. Janshuis Celestijnenlaan B-3030 Heverlee, Belgium

- Joseph Melotte Zandheuvel 1, Appt. 123 B-8401 Bredene, Belgium APPENDIX D

Participants at Marseille meeting, 12 - 14 May 1982

Beatrix Westhoff Sozietat fur Enwicklungsplanung (SFE) Friedrichstrasse 38, 6000 Frankfort, West Germany

Elisabeth Gern Karen Kennedy Aprovecho Institute 442 Monroe St. Eugene, Oregon 97402 USA

Ralph Royer Church World Service B.P. 11624 Niamey, Niger

Michel Taymans Agence Internationale du D veloppement Rural (AIDR) 20, rue du Commerce B-1040 Brussells, Belgium

Beauchesne Patrick CTFT 45 bis Bd. Belle Gabrielle 94130 Nogeret/Marne, France

Annette Legris FIEF 5, av. Porte Braucion 75015 Paris, France

Patrick Hauser Etudiant 16, rue des Samfoins 77380 Combe la Ville, France

Bernard Kauffmann GRDRP 145, rue St. Dominique 75007 Paris, France

Pedro Costez ICADA-Choqui Apartado postal 159 Quetzaltenango, Guatemala, C.A.

Roberto Caceres ICAITI Apartado Postal 1552 Avenida la Reforma 4-47, Zona 10 Guatemala, Guatemala, C.A.

Malcolm Lillywhite D.T.I. Box 2043

Philippe Simonis G.T.Z. Postfach 5180 Dag-Hammerskjoldweg Eschborn 1, West Germany

Yvonne Shanahan Stephen Joseph ITDG A.R.S. Shinfield University of Reading Whiteknights Reading RG6 2AH, United Kingdom

Sylvain Strasfogel Association Bois de Feu/GRET 73, avenue Corot 13013 Marseille, France

G. de Lepeleire Katholieke Universiteit Leuven Waversebaan 178 B-3030 Heverlee, Belgium

Woodstove Group Technische Hogeschool Eindhoven (THE) Postbus 513 5600 MB Eindhoven, The Netherlands

Mr. W.J. Weerakoon T.D.A.U. University of Zambia P.O. Box 32379 Lusaka, Zambia

Mme. Seck CERER B.P. 476 Dakar, Senegal

E. Ferguson van Dormaalstraat 15 Eindhoven, The Netherlands

Alice Guidicelle 200, rue de la Loi B-1049 Brussels, Belgium

Cherif Zaouch ITTA Sidi-Bau-Ali 4040 Tunisie

L. Van Daele ATOL Holsbeeksesteenweg 117 B-3200 Keseel-Lo, Belgium

FEISEAP Faculty of Engineering Chulalongkorn University Bangkok 5, Thailand

Tata Research Institute Bombay House 24, Homi Mody Street Bombay 400023, India