Published By VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703-276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Solar Cookers and Ovens ISBN: 0-86619-247-6 [C] 1985, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100.titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Giannuzzi as editor, Suzanne Brooks handling typesetting and layout, and Margaret Crouch as project manager.

The author of this paper, VITA Volunteer Thomas E. Bowman, is Professor and Head of the Mechanical Engineering Department at the Florida Institute of Technology in Melbourne, Florida. The reviewers are also VITA volunteers. Mikos Fabersunne is a mechanical engineer employed with the Office of Energy Assessments for the State of California in Sacramento. Gary Flomenhoft is a senior test engineer with TRW in Redondo Beach, California. John D. Furber is President of Pleasant Valley Software Corporation and Starlight Energy Technology in Aptos, California. John Yellot is Professor Emeritus of the College of Architecture at Arizona State University, and operates John Yellot Engineering Associates, a consulting engineering firm specializing in the use and control of solar energy.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

In many equatorial regions, native trees and bushes are being cut at an alarming rate to meet the growing demands for agricultural land, industry, and fuelwood and charcoal. The environmental consequences of this deforestation are severe, ranging from soil erosion and climate changes to flooding and the destruction of farmland. Moreover, dwindling supplies of wood mean that people must spend more time and energy in the search for cooking fuel.

One alternative is to use kerosene, gasoline, or liquified petroleum gas. But these are often imported (hence expensive) and transporting them to remote areas is usually difficult.

The next obvious alternative is to use the sun, particularly in equatorial regions where solar energy is abundant. However, although workable solar cookers have been developed, many have serious limitations. For example, except for the indirect cookers, most can only be used outdoors and during the day (and often only when the sun is high), most have to be adjusted every 10-15 minutes to keep pace with the moving sun, and most are suitable only for slow cooking and stewing. In addition, some designs can only accommodate one cooking pot.

Since even the best aren't as fast as stoves using conventional fuels, they are most suitable in conjunction with traditional methods, (i.e., using a solar cooker during the day and a fuel-burning stove at night, thereby conserving fuel and helping to alleviate the deforestation problem).

HISTORY OF SOLAR COOKERS

Research and development of solar cookers began over 100 years ago. W. Adams of Bombay, India, designed one in 1876 that consisted of an octagonal, glass-enclosed oven surrounded by glass mirrors that collected the sunlight and directed it into the enclosure. The span of the reflector rim was 71 cm.

Adams reported that it cooked "the rations of seven soldiers ... in two hours, in January." (Sunshine Cooks Ltd., a manufacturer of solar cookers in the United States, is now marketing a similar cooker that has a somewhat smaller enclosure and larger reflector (94 cm).

One of the first indirect solar cookers (permitting cooking at night and indoors) was designed by Dr. Charles Greely Abbot of the Smithsonian Institute. This used hot oil in narrow metal tubing to take the heat from the solar collector to an insulated heat storage tank, and from there to the stove. The cooking element consisted of a tight spiral of copper tubing through which the hot oil flowed before returning to the storage tank.

Also, in 1981, Dr. Chang Sung-Ying of the Solar Energy Research Lab in Chen Chow, Hunan, reported that "several types of solar cookers have been developed" and thousands were operating in rural China. One developed in his lab was a direct-focusing cooker that was being sold outside of China in 1981 for $150.00 (U.S.) Some were also displayed in the China pavilion at the 1982 World's Fair in Knoxville, Tennessee.

During the late 1950s, two primary types were invented: (1) the direct-focusing cooker, in which a pot is supported at the focal point of a parabolic (or closely similar in shape) reflector; and (2) the Telkes oven, in which cooking pots are placed inside an insulated oven, one of whose walls consists of a window, usually double-glazed, surrounded by an array of plane reflectors.

The direct-focusing cookers are typically the least expensive to build and achieve the fastest cooking times (at least for small quantities of food). Telkes ovens are much more expensive to build aside from the large reflector area and two large pieces of glass for the window, the oven requires both inner and outer sheet metal boxes, high-temperature insulation and a door. Compared to direct-focusing cookers, however, these ovens are easier to use, cook greater amounts of food, protect it from blowing dirt, and keep it warm. They can also operate for long periods without maintenance.

From 1957 until some time in the 1960s, over 200 direct-focusing cookers were tested in Mexico. Designed and developed at the University of Wisconsin, they had rigid plastic reflectors with reflective films bonded to the front surfaces. The mechanical failures that appeared during the first tests were corrected by redesigning. But although successful, those who used it regarded it as just a novelty, and after a few months, went back to their traditional methods. The cookers in the last tests were locally-built with polyester shells, reinforced with muslin cloth and burlap, and a number of small glass reflectors glued to the front surface. But those were used only until the glass mirrors fell off.

Attempts to introduce solar cookers in Mexico probably failed for a number of reasons:

- The burdensome need to replace periodically all or part of the solar cooker's reflective surface, whether plastic foil or glass pieces. Also these materials were not available locally and required a certain skill to install.

- Some operating characteristics of the solar cookers (i.e., the need for frequent attention while cooking, exposure of the cooking pot to blowing dust and sand, and lack of heat storage) were unattractive.

- Alternative cooking fuels, such as kerosene and wood, were readily available at the time.

- They had not been used traditionally and they could not be cleaned with sand!

In the late 1950s and early 1960s, two companies in India manufactured a large number of direct-focusing solar cookers equipped with parabolic reflectors made of polished and anodized aluminum which meant they did not need the tubes replaced as often. But many in India refused to cook outdoors because of health and religious regions.

Since the introduction of solar cookers in Mexico and India over 20 years ago, solar cooking technology has not changed much in the case of direct-focusing cookers. What has changed, however, is that people in developing countries may no longer have any choice but to adopt them because traditional cooking fuels are disappearing. Indeed, there are large areas where locally-available combustible materials simply do not exist anymore, and where petroleum-based fuels are not easily available.

II. DESIGN VARIATIONS

Generally speaking, solar cookers fall into three categories: (1) direct-focusing cookers, (2) oven cookers, and (3) indirect cookers.

DIRECT-FOCUSING COOKERS

A direct-focusing cooker uses a reflector to focus sunlight directly onto a dark cooking pot which is either suspended or set on a stand at the focal point. It consists of one or more reflectors and a framework that supports both the reflector and the pot. Numerous arrangements of this cooker have been devised to allow the reflector to be tilted to always point toward the sun, with the pot remaining at the focal point.

Various types of reflectors can be used:

- a plastic shell, parabolic or spherical in cross-section, lined with a reflective plastic film such as aluminized Mylar, aluminized polyester, or reflective acrylic (e.g., "Scotchcal");

- a plastic shell, as described above, with a mosaic of small glass mirrors glued to the inside;

- various types of clay or pottery shell, lined with a reflective film or small glass mirrors;

- a woven shell ("sun basket"), smoothed on the inside with papier mache and lined with a reflective film;

- various cardboard fabrications lined with reflective film;

- various rigid foam shells, lined with reflective films;

- a Fresnel-type lens that consists of a series of concentric hardboard rings, lined with a reflective film (*);

- a spun aluminum shell, polished and anodized;

- a folding fabric and metal device very similar to a large umbrella, with a reflective film on the inside;

- one or two fan-shaped arrays of individual metal reflectors, designed to collapse into a compact package;

- a fixed array of individual focusing reflectors such as shaving mirrors.

(*) VITA can provide detailed plans for this system.

A number of schemes have been devised to make reflector shells in the field, but all still require highly-skilled artisans to produce an accurate surface. (Factory-produced shells, whether injection-molded plastic, molded fiberglass, spun aluminum, or some other material, should be considered whenever feasible.)

The reflector, if it is in one piece, should be about 1.0 to 1.5 meters in diameter to permit the cooking of moderately large amounts of food. If it is in several pieces, the total area should be comparable. Although cooking with much smaller reflectors has reportedly been successful, small reflectors mean less food can be cooked and sunlight conditions must be more favorable.

Although some of the direct-focusing cooker designs offer good performance at comparatively low initial cost, they have a number of shortcomings and special design considerations:

- The cooking pot is exposed to many hazards, including blowing sand and dirt, children playing, mishandling, etc.

- Direct-focusing cookers are much less versatile than ovens. They cannot, for example, be used to cook two dishes at the same time, or to keep food warm. Cooking is done in a single pot.

- The wind load on the reflector of a direct-focusing cooker can be quite high due to the large size of the reflector. Therefore care must be taken in the design so that the cooker will not tip over easily.

- The materials used in some designs, such as hardboard or cardboard, deteriorate if kept outdoors.

- The older reflective films have limited lifetimes when left outdoors, as do the adhesives used to hold them in place. The need for frequent replacement of these reflective films and adhesives increases the operating cost and makes it comparable to that of a kerosene stove. Thus far, "Scotchcal" seems to work much better.

- All reflective films scratch easily, and consequently must be cleaned very carefully.

- In some cases, direct-focusing cookers with long focal lengths may hurt the eyes.

- Since direct-focusing cookers use only the sun's direct rays, they work poorly on hazy days, and a cloud passing overhead will temporarily "turn off" the cooker. Generally, direct-focusing cookers need to be adjusted every 10 to 20 minutes to face the sun.

- Aluminum reflectors, the only really permanent solution, should be electropolished (or, at the very least, machine buffed) to obtain good reflectivity, and anodized to keep their reflectivity. Solar cookers equipped with aluminum reflectors result in high initial costs compared to designs using reflective films.

- Applying a reflective film to a doubly-curved (compound curvature) surface requires a high level of skill. The film must he carefully cut into many small pieces, fitted to the shell, and bonded to avoid bubbles and other imperfections. Even applying a film to a flat surface requires considerable practice and patience.

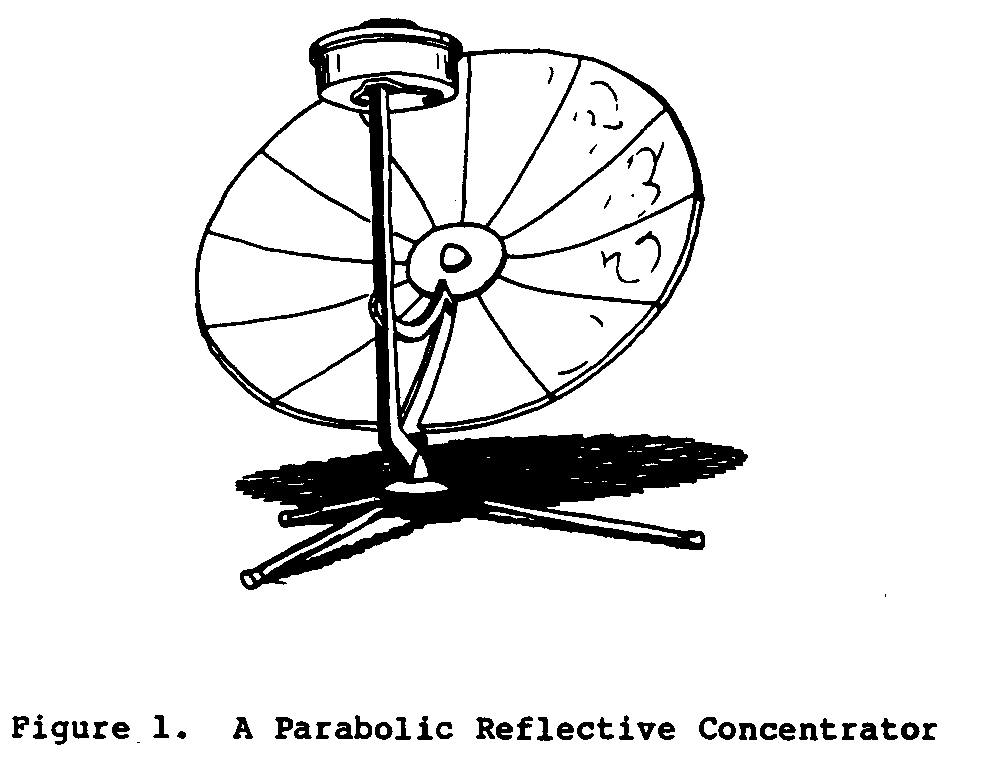

Figure 1 shows a direct-focusing cooker consisting of a parabolic

dish.

OVEN COOKERS

A solar oven is an insulated box with a glazed cover that cooks food through the "greenhouse effect." Sunlight enters the oven through the glazing and heats the dark inside walls and cooking vessels. Since the heat cannot escape through the glass, the oven gets very hot. Mirrors around the window send even more sunlight into the oven.

<FIGURE 2>

Oven cookers are more versatile than direct-focusing cookers because they can use either direct or diffused sunlight. The temperature, which may exceed 200 [degrees] C (328 [degrees] F) when reflectors are used, is hot enough for almost any kind of cooking except frying. In addition, many foods can be slow-cooked without adjusting the cooker to track the moving sun.

Solar ovens tend to be heavy and more stable in wind. They also retain heat longer than direct-focusing cookers. For example, a properly designed cooker with an insulated cover can retain temperatures of 150 [degrees] C (238 [degrees] F) for an hour after sunset. Bricks, stones, and other heat storage media also may be placed in the oven to retain heat even longer, although they do cause the oven to heat up more slowly initially.

A wide variety of oven cookers have been developed over the years. Those described in this section are grouped into three categories according to their concentration ratios: (1) low-concentration ovens, (2) medium-concentration ovens, and (3) high-concentration ovens.

The concentration ratio is the ratio of the total intercepted area of incoming sunlight to the area of the oven window. For example, if the entire cooker, including reflectors, is seen by the sun as a 1.0 meter square object, and the window is a square, 50 cm on a side, the concentration ratio would be four. (The definition assumes that the oven is designed and set up properly, so that all the sunlight hitting the reflectors is reflected through the window.)

Low-Concentration Ovens

Low-concentration ovens are those with concentration ratios of one (no reflectors) or slightly greater, but less than two. In this category, the most important general types of oven cookers are box cookers and pit cookers.

Box cookers. Box cookers are shallow boxes sitting flat on the ground, usually insulated, with either single-layer or double-layer glass covers. Sometimes, a single-plane mirror is used to increase the amount of sunlight entering the window.

The box is normally not tipped to face the sun, and hence a reflector can greatly increase the amount of sun entering the cooker when the sun is low in the sky, even though the maximum increase is only about 60 percent with the sun directly overhead.

To reduce heat loss from the sides, the box is normally fairly shallow, and the kinds of pots and other items that can be placed in the oven are limited as a result of the low concentration ratio.

Unless a reflector is used and moved to follow the sun, a box cooker will only be effective when the sun is more than 60 [degrees] above the horizon. Within about 5 [degrees] to 10 [degrees] of the equator, it could be during the middle of the day whenever the sun shines. At 30 [degrees] latitude it could only be used from about March 21 to September 21 (or vice versa in the southern hemisphere), near the beginning or end of this period, the daily usable period would be very short. As a practical matter, the use of a horizontal box cooker without a reflector would be limited to tropical latitudes, and even there other forms of cooking might still be necessary during a part of the year except for those living within about 1,000 kilometers (km) of the equator. The farther from the equator, the more useful a reflector.

In mainland China, this limitation has been overcome by using box cookers tipped at fixed angles. The interior of such cookers is evidently somewhat complicated, with tiers of small horizontal shelves. The fixed tilt angle still means that the cooker will perform well for some sun positions and not for others, just as a horizontal box would but without the latitude limitations. Although much cheaper to build than most others, box cookers should be considered only where their limitations are not critical. The box itself can be made of wood, plywood, chipboard, etc., provided an "exterior grade" is used and the exterior of the box is well painted. The bottom and sides of the box should be very well insulated (insulating materials are discussed in Section III) and a black tray fitted above the insulation, preferably supported by clips or brackets on the sides of the box rather than resting directly on the insulation. The glass cover should probably be fitted with a frame and handles to make it easier to lift on and off. A well-fitting latch to hold the cover and the box together is highly desirable.

Pit cookers. Pit cookers are pits dug into the ground and lined with insulating material such as wood chips or rice husks. The oven itself can be a box or clay pot, etc., with a glass cover. These are even easier to build than box cookers because they do not require an insulated box. However, the limitations that apply to box cookers also apply to these, and they cannot be moved around to follow the sun.

Medium-Concentration Ovens

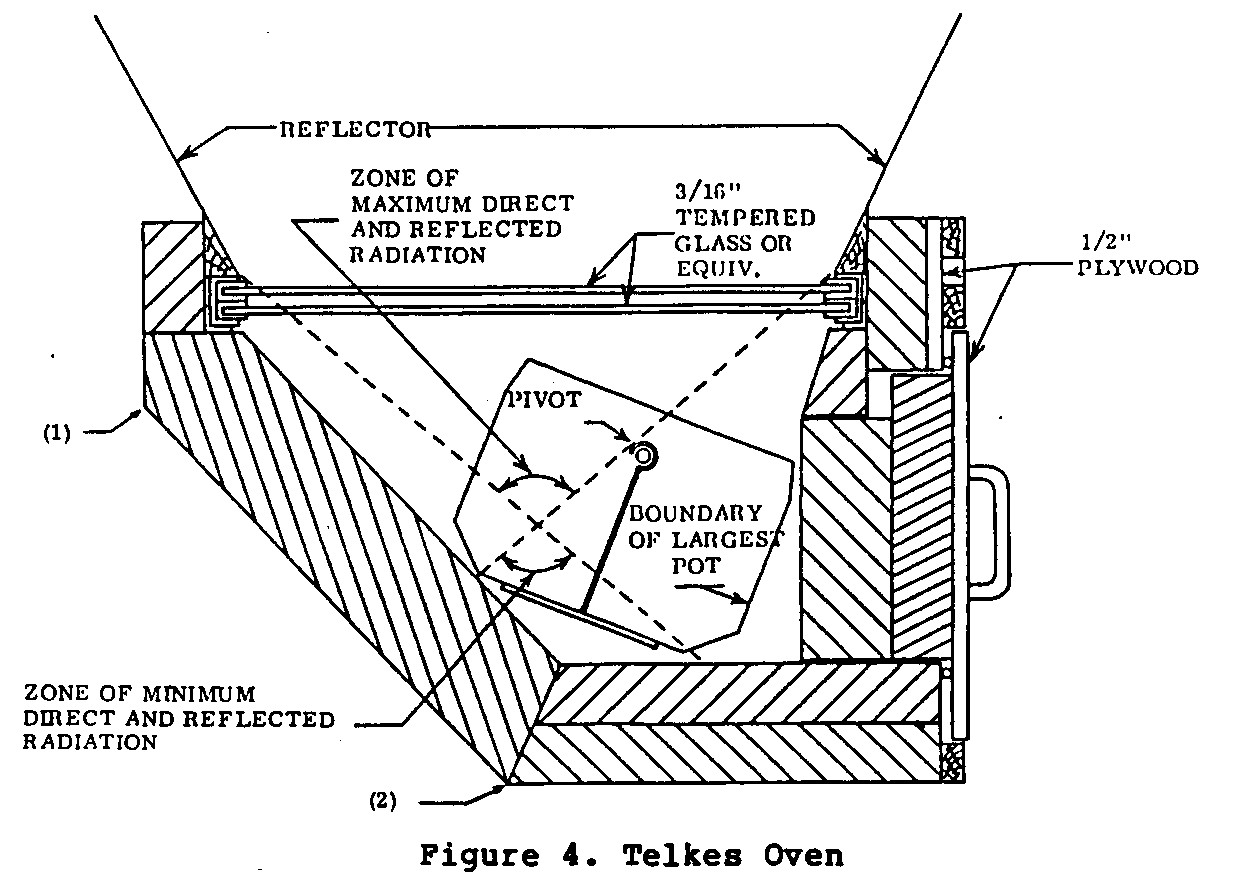

Medium-concentration ovens are those with concentration ratios between two and five. The two best-known general types of solar ovens--Adams cookers and Telkes ovens--fall into this category. The oven enclosure in a Telkes oven is made up of insulated walls and a transparent front cover (like a box cooker except that it is three-dimensional), whereas in an Adams cooker, the oven enclosure is transparent except for an insulated back surface. In both types, the transparent surface is surrounded by reflectors.

Figure 3 is an illustration of the original Adams cooker built around

1878. Figure 4 shows a Telkes oven built at the Florida

Institute of Technology (FIT) in 1980.

For good performance with either type, the entire oven and reflector must be kept pointing more or less in the direction of the sun. The oven may need to be moved as much as once every 10 minutes or as little as once every 60 to 90 minutes, depending on the design of the oven and the position of the sun.

Other configurations could be devised that would produce ovens with concentration ratios of two to five. (All existing medium-concentration solar ovens can be described as either Adams cookers or Telkes ovens.)

The Adams cooker, (although somewhat more expensive than a box cooker), can be used later (or earlier) in the day, and at higher latitudes, since it can be pointed at the sun. Its relatively high concentration ratio also means it reaches higher temperatures and can be used on cool or cold days; similarly, the wind is less likely to keep it from reaching cooking temperatures. It is not as easy to build as a box cooker, but much easier than a Telkes oven or a direct-focusing cooker, and should also have a lower material cost than a Telkes oven, especially if the glass enclosure for the cooking space can be mass-produced. (If the glass enclosure has to be made in the field using pieces of flat glass, it might be best to consider a different type of cooker.) It should also be kept in mind that the glass enclosure gets quite hot, and must be handled while hot. The only access to the food being cooked is by removing the glass enclosure and then replacing it.

Like the Telkes oven, the Adams cooker is far easier to use if fitted with a swinging rack on which to place the food. Adjustable racks that can be set up at various angles are not very satisfactory, especially if the tilt angle of the cooker keeps changing to follow the sun. A swinging rack will keep the food from spilling during reasonably minor movements of the cooker, with no need for opening the heated enclosure.

The greatest disadvantage of the Adams cooker is the small cooking space. Thus, the Telkes oven may be preferable, despite its higher cost. With the Telkes oven, it is necessary to build both an oven and a reflector array, and then fit them together. The oven should have heat resistant inner walls (i.e., sheet metal) with insulation in between the inner and outer walls, a large window on one side, and a door on the other, making it rather complex to build; the services of a sheet metal shop are almost essential. The window is large, and needs to be strong (two layers) or it will break easily. Attaching individual reflectors directly to the oven, so that they surround the window, is usually unsatisfactory due to both the wind loads on the reflectors, and the normal daily bumps and knocks. Instead, the reflectors should be attached to a separate sheet metal structure with a stiffening outer ring.

Durability is important in a Telkes oven because one of its most attractive features is that it can be used all day, dragged around to follow the sun, and tipped from horizontal at sunrise to vertical at noon and back to horizontal in the evening. Because it has a roomy interior, it tends to be big. But it can withstand a lot of abuse.

One of the main reasons the Telkes oven is perhaps the most expensive type to build is because the total area of reflective material is much greater than in any other cooker for a given total amount of sunlight collected. (This is because of the small angle--30 [degrees]--between the incoming sunlight and the reflector surface.) On the other hand, it is an extremely versatile cooker than can accommodate several large pots of food at one time, can heat a pot of cooking oil to 230 [degrees] C, can keep some food warm while others are cooking, and that can keep food warm well into the evening if a blanket is draped over the window.

When building a Telkes oven, there are two paths to failure: (1) making the oven too large relative to the size of the window and reflectors; and (2) using materials, including insulation that cannot withstand high temperatures. Regarding the size of the oven, the primary concern is with total surface area rather than with volume. It is therefore essential to design an oven that makes the most efficient possible use of its interior volume. At the same time, though, it is helpful to be able to tip the oven up and down to face the moving sun without spilling the food being cooked. This can be done by installing a tray that swings in and out of the oven. Note, however, that it may be difficult to satisfy both the need for minimum wall area and the need for a swinging rack.

High-Concentration Ovens

High-concentration ovens are those with concentration ratios greater than five. Such ratios are obtained by elevating the ovens over focusing reflectors or arrays of reflectors. Focusing reflectors used in a solar oven normally have a simple curvature, resulting in a line focus, since the objective is to heat the inside of the oven rather than a specific target. If an array of plane reflectors is used, each reflector is usually about the same size as the window, and the theoretical concentration ratio is therefore equal to the number of reflectors. (The concentration ratios realized in practice are lower, because when the sun is high in the sky the oven casts a shadow on some of the reflectors, and when it is low the projected area of the reflectors is lower than the actual area.)

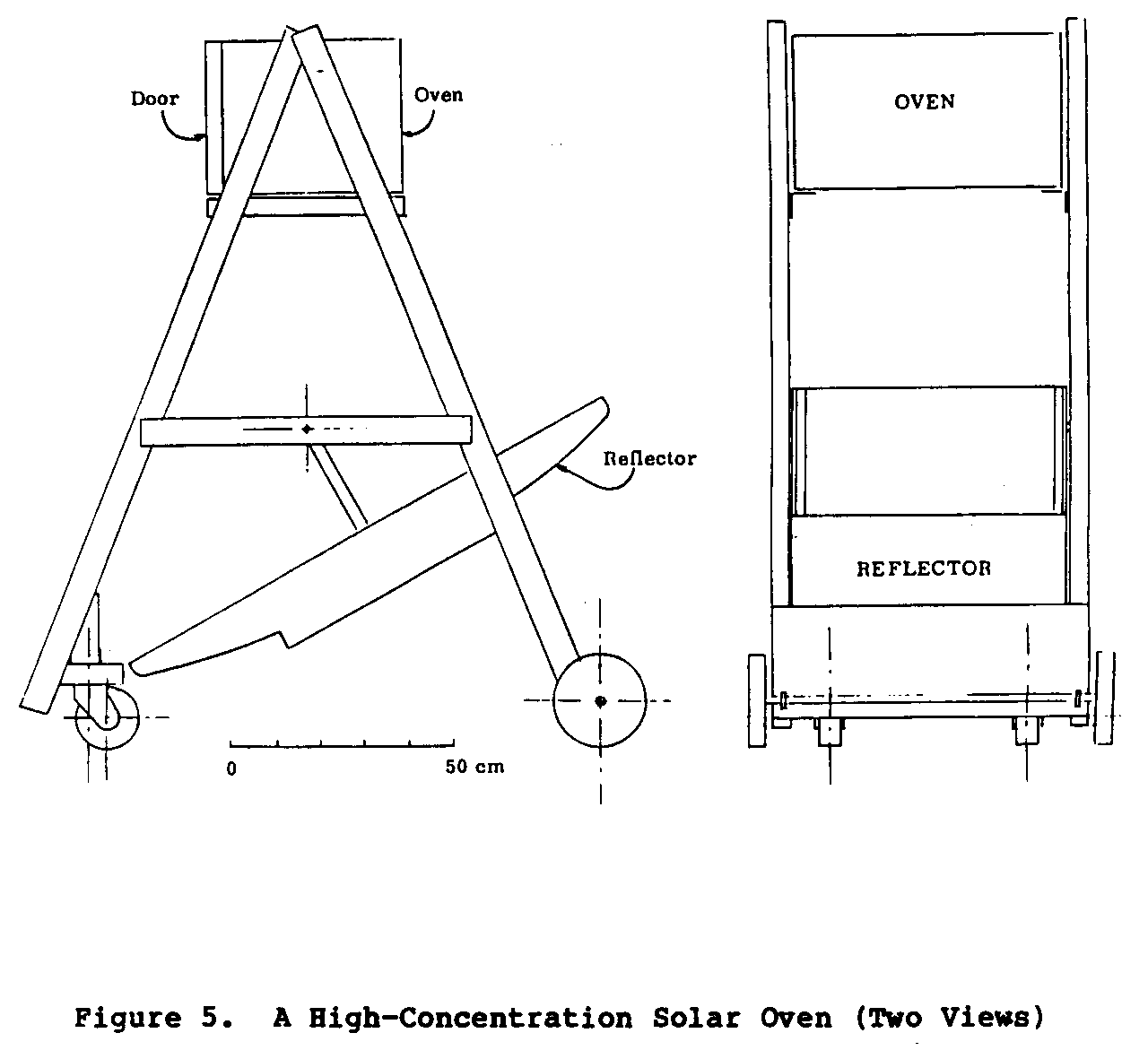

The cooker shown in Figure 5, which was developed at FIT, uses a

single parabolic reflector with its vertex near the rear edge, pivoted about the center of a circle passing through the ends of the parabola and the focal point. Even at low sun angles, a reflector designed along these lines stays closer to the ground and closer to a vertical line through the oven window than would be the case with a symmetric reflector or a higher pivot axis, as in Prata's design. Hence, more energy enters the oven since the window is long and narrow, and is at the bottom of the oven, the focus is a sharp line for one reflector position and a broader line for other positions.

In operation, the entire oven is turned periodically about a vertical axis to face the sun, while the reflector alone is tipped to follow changes in the sun's elevation. Proper reflector angle is indicated by the location of the bright focal line on the window, and is maintained by letting the reflector rest against an adjustable support rod.

The window is wide enough to allow periodic rather than continuous adjustment of the reflector. The reflector is typically adjusted so that the focal line is at one edge of the window (the focus is on the back edge in the morning, and on the front edge in the afternoon). As the sun rises or sets with the reflector stationary between adjustments, the focal line, which is very bright and hence easily seen, moves across the window. When it reaches the opposite edge, the reflector should be adjusted to move the focus back to the original edge. Adjustment is typically needed every 10 to 15 minutes.

The reflector can be made in almost as many different ways as the reflectors used in the direct focusing cookers described earlier. Its curvature is simple, so a single sheet of metal will do. Since both the area of window and the reflector are much smaller for a given oven size than in the Telkes oven, the material cost is less. The materials for the oven itself are essentially the same as in a Telkes oven, and the frame can be built fairly cheaply in most developing countries, though the skills needed to build it are somewhat higher because of the need for an accurately configured reflector. Also, it is a little easier to use than a Telkes oven, since the oven stays horizontal, opens in a "normal" fashion with a hinged, vertical door, is located off the ground and is heated from below rather than above. Most of the advantages of the Telkes oven relative to direct-focusing cookers also apply to this design. However, it does not perform as well as a Telkes oven of comparable size because the oven shades part of the reflector. Also, the size of the reflector is limited because it must be able to clear the ground as it swings. The higher the oven relative to the ground, the larger the reflector can be and the higher will be the temperature reached by the oven.

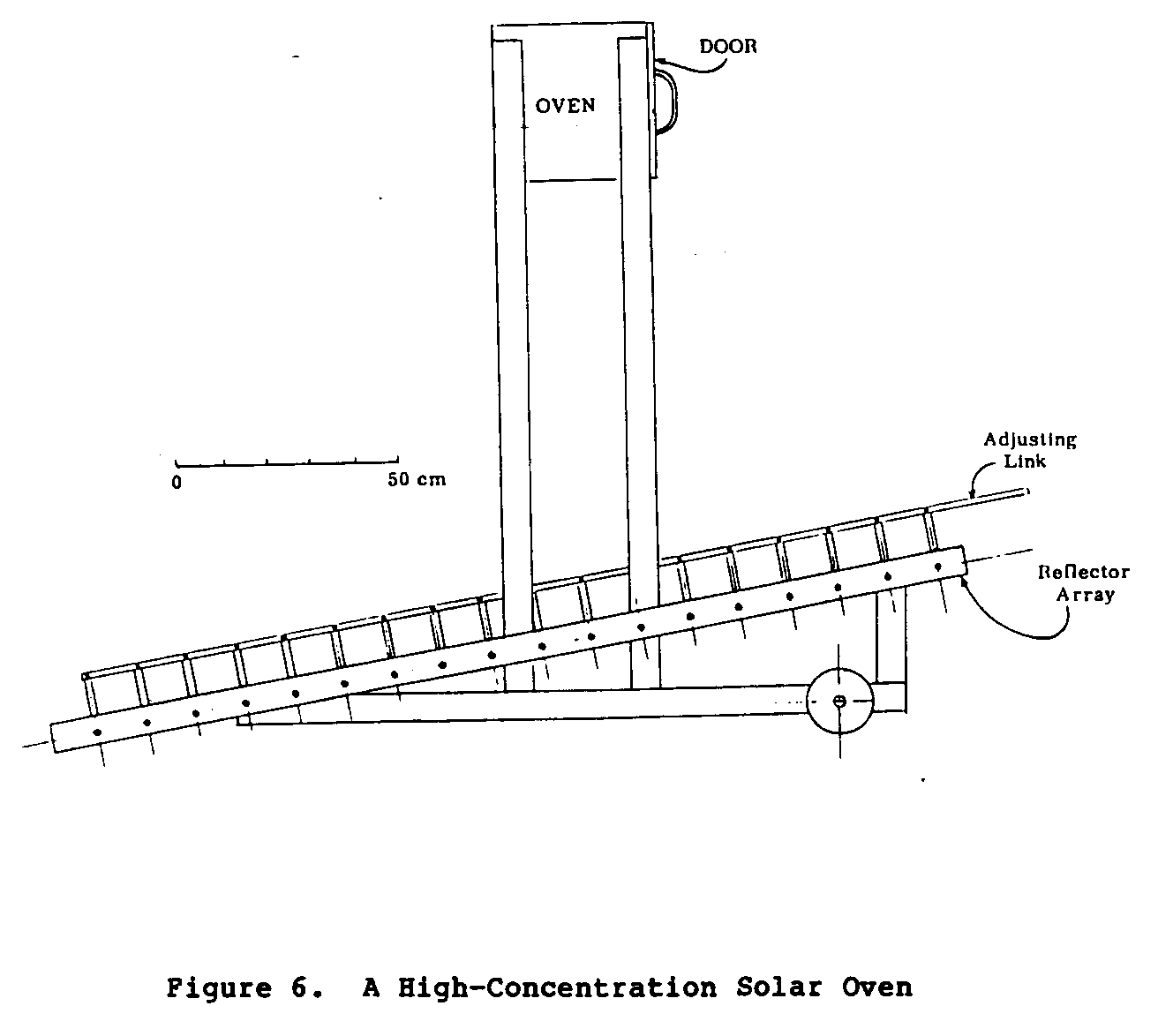

The solar oven shown in Figure 6, also designed at FIT, was

designed to overcome this limitation on reflector size. Here, individual reflectors pivot about their own central axis and are controlled through appropriate linkages by a single operating lever. To follow the sun, the whole oven is rotated and the operating lever is moved to shift the patch of reflected light from the oven shell onto the window. If the individual reflectors are plane, glass mirrors may be used; if they are curved, fewer reflectors are needed because they can be larger. In the latter case, each reflector should have a circular cross-section, with a radius twice the distance from the reflector to the window. The need for accurate reflector shape is much less critical than in the single-reflector case because the individual reflectors are smaller.

A comparison of the two FIT cooker designs indicates that the multi-reflector version has much higher performance, but at the cost of greater complexity and many more moving parts. Total material cost of the multi-reflector cooker is also somewhat higher than the other FIT design, although still lower than that of a comparable Telkes oven. Both FIT versions are more difficult to build than a Telkes oven. Neither these nor Telkes ovens can be constructed in the field. Building FIT cookers also requires a drill press and many careful measurements, which are not needed for Telkes ovens. Compared to direct-focusing cookers (and except for the reflectors), FIT ovens can be sturdy and require little maintenance.

Of all the solar cookers, the FIT and Telkes ovens are probably the easiest to use and the most versatile. The temperatures of over 200 [degrees] C that a large Telkes oven is capable of reaching have not been achieved in FIT cookers of reasonable height, but an FIT cooker can reach about 150 [degrees] C, which is adequate for most purposes. FIT cookers should be considered only if local workshop facilities are available for their construction.

INDIRECT COOKERS

These are the only solar cookers that can be used indoors. In an indirect cooker, the enclosure where the food is cooked does not receive solar energy directly. Instead, a solar collector, separate from the cooking chamber, receives sunlight to heat a working fluid--usually either a vegetable oil or water. The hot fluid then travels through a pipe to heat the cooking enclosure.

In 1964, Whillier of the Brace Research Institute, built an indirect cooker consisting of a horizontal finned pipe at the focus of a stationary circular-cylindrical reflector, connected at one end to a double-boiler cooker. Water in the pipe boils, sending steam to the cooker, where it condenses on the outside of the cooking pot. The aperture area of the reflector was 1.3 square meters. One of their later designs consisted of a stationary flat plate solar collector inclined at a 45 [degrees] angle, with a double-boiler cooker mounted on top of the collector (see Figure 7). In this

design, steam from the collector rises to the cooker, where some escapes and the rest condenses and runs back to the collector. However, when twenty of these were installed at a school in Haiti in the early 1970s, most were eventually dismantled when they failed to work properly. (Dr. Erich Farber of the University of Florida, however, reports that he is currently using several of these cookers with very good results.)

Indirect cookers have many disadvantages. If, for example, an indirect cooker uses atmospheric pressure steam as a working fluid, the maximum possible cooking temperature is below the boiling point of water, and thus is suitable only for slow cooking and stewing. Moreover, the insulated cooking box is small. This limits the size of the pot and the amount of food that can be cooked. And because most indirect solar cookers are immovable units, they cannot be adjusted to track the sun. As a result, they are useful only part of the day. Finally, efficient flat plate solar collectors are difficult to build in the field, and some important components (e.g. low-iron glass) are not readily available in small quantities. These collectors also use more glass than other solar cookers. On the other hand, if the flat plate solar collector is purchased as a unit, building the rest of the cooker is relatively simple and cheap.

III. DESIGNING THE SOLAR COOKER RIGHT FOR YOU

SUMMARY COMPARISON OF SOLAR COOKERS

The main cooker types discussed previously have advantages and disadvantages that can be summarized as follows:

- Direct-focusing cookers offer high cooking temperatures at a relatively low cost, but have a number of disadvantages for everyday use as the primary means of cooking meals. They are also unsatisfactory in windy conditions, or in hazy sunlight. Some designs are suitable for on-site construction, but typically have high maintenance costs. Shop-built reflectors should be considered if at all feasible. Workers building these cookers should have a fairly high level of skill. + Box and pit cookers are inexpensive and easy to build, and are effective cookers within their limited range. ey do not accommodate large cooking pots, and cannot be used in areas far from the equator or in the early morning or late afternoon, although these latter two problems can be alleviated by modifying the basic design. Worker skills need not be as high as with other types of cookers.

- The Adams cooker is probably adaptable to on-site construction if a tempered-glass oven enclosure can be mass-produced (to reduce unit costs), and distributed. It offers good performance and simplicity at a cost somewhat higher than a box cooker, but lower than most other oven-type cookers. Worker skills required are comparable to the box cooker, and less than for other oven-type cookers or direct-focusing cookers. It is also is suitable for a wide range of latitudes and weather conditions, and is less affected by windy conditions than some other types.

- Telkes ovens generally offer the highest performance of any of the oven cookers, but also have the highest material cost. Building one normally requires the services of a sheet metal shop. They can be very durable and versatile, and work well in a variety of wind and weather conditions, latitudes, and times of day. The cooking enclosure is larger and easier to use than that of an Adams cooker, but not as easy to use as those found in high-concentration cookers. + High-concentration solar ovens separate the oven from the reflector, making the oven much easier to use. Material cost is also lower than a Telkes oven, but higher than most other types. The primary disadvantages are their greater complexity relative to other solar cookers, and the need for a sheet metal shope and machine tools for construction. Their wide range of usefulness parallels that of Telkes ovens, except that they do not make effective use of diffuse sunlight. However, further design improvements may alleviate some of the construction difficulties. + Indirect solar cookers have as their chief advantage the possibility of indoor cooking. They are also sturdy and stable and little affected by wind and cold weather. But, they should probably not be considered unless good-quality, shop-built flat plate solar collectors are available. Except for the collector, they are easy to build and are low in material cost. If steam is the heating media, they have very low maximum temperatures (i.e., they cannot boil water or fry foods). Most designs can be used only part of the day since they cannot be rotated to face the sun.

USE OF LOCAL RESOURCES

Most solar cooker designs require insulating material, and either glass mirrors or polished aluminum reflectors. These items, however, are seldom found in rural areas, and often must be imported. Many cooker designs also use steel or aluminum sheet metal and/or structural steel or aluminum, which are usually available only in larger towns and cities. Hardware, such as nuts and bolts, hinges, wheels, and door catches, are also often required in many designs.

The skills needed to build most of these cookers include basic sheet metal bending, cutting and welding, drilling holes, etc. But even workers experienced by local standards may need close supervision to turn out an article that is unfamiliar to them.

Some designs, especially those of direct-focusing cookers, make use of indigenous materials such as bamboo, and local crafts such as basket-making and pottery. But these designs still require imported reflective films and adhesives, since using anything less than the best will result in more maintenance and decreased performance. It is certainly easier to import reflective film than reflective aluminum, though importing the latter may be cheaper in the long run if it requires fewer special skills for construction and less maintenance.

Although it may be possible to use indigenous materials for insulation, (clay, sand, dirt, rock, bricks, etc.) most make poor insulators. Some inorganic materials that can be used to include volcanic rock and tuff. As a rule of thumb, any lightweight non-metallic inorganic material is probably an effective thermal insulation. Typically, such material will appear porous or foamy.

Organic insulating materials such as rice husks, shredded paper, cardboard, wood chips, or tree bark are better, but most need to be kept dry and this is often difficult. And while cork is an excellent insulating material that is impervious to moisture, it may not be able to withstand high cooking temperatures.

Fiberglass batts, one of the world's most readily available commercial insulating materials, seems to be limited to a maximum temperature of about 150 [degrees] C, and it has little or no resistance to moisture. And while the fibers themselves should be good to well above 450 [degrees] C, and are not affected by moisture, they are difficult to work with in their natural state and their insulating qualities are disappointing.

Urethane foam, either in the form of boards or as a foam-in-place kit, is one of the best insulating materials commonly used in the United States because of its low thermal conductivity. But manufacturers of urethane foam point out it has an upper temperature limit of about 150 [degrees] C, and at high temperature it gives off poisonous vapors. It is also quite expensive, especially in kit form.

Common asbestos board has a very high temperature limit, but a thermal conductivity five or six times higher than fiberglass board. It also costs about five times as much and poses a serious health hazard.

Firebrick, a lightweight porous brick, twice as good as asbestos board, is not much cheaper. Calcium silicate is cheaper and a better insulator, but is subject to water damage. Compared to fiberglass board, its conductivity is about 50 percent higher and its cost about twice as high, but its upper temperature limit is not a problem at all.

"Foamglas," another insulating material that can be manufactured from waste glass in a very simple shop, is much cheaper than calcium silicate, with a slightly better (lower) thermal conductivity and nearly as high a maximum temperature. It is also non-toxic, not at all affected by moisture, and has good rigidity and compressive strength. Its rough, black surface is also a good absorber of sunlight. The chief disadvantage is that everything that touches it rubs off rough, gritty particles. An experimental oven has been built entirely of foamglas, with no metal parts.

SCALE

Thus far, no attempts have been made to design and test very large solar cookers that could be used by several families or an entire village. Until this work is undertaken, it is difficult to speculate how the design of very large cookers would differ from smaller ovens. Perhaps special platforms could be built to give access to ovens far above the ground, etc. However, unlike small single-family units, large ovens would be hard to move unless they could be rotated by turntables resting on fixed pedestals.

POSSIBLE PROBLEMS TO CONSIDER

So far we have limited our discussion to the technical problems and economics of various types of solar cookers. But they must also be socially acceptable. In one sense, the problems of social acceptance are often overstated, because if the need is great enough and the solar cookers are good enough, they will be accepted. On the other hand, though, solar cookers still have many technical imperfections that require correction if they are to be accepted in any culture.

One problem with solar cookers is that they don't work when the sun doesn't shine. There is a lot of difference between our perceptions of the weather in any particular location, and what the weather actually is. Many areas are not as sunny as they may seem.

Another problem with solar cookers--or, for that matter, any new piece of equipment--is that in many parts of the world, especially the rural areas of developing countries, a solar cooker tends to be taken out of service for long periods, even though it may have suffered only minor problems. Solar cookers will probably not be successfully introduced in large numbers in any of these countries unless a team of solar cooker technicians can be formed and maintained, even if they do nothing more than tighten screws, oil pivots, and clean windows and reflectors. Ideally, these technicians should know where all the solar cookers in any given district are, inspect each one regularly, put it back in service if it is not being used, service it even if it is being used, and remind the user of some of the basics of using and maintaining it.

MARKETING/DISSEMINATION

There are many problems blocking the widespread introduction of solar cookers. To overcome these problems, a solar cooker marketing and dissemination program should adopt several strategies.

First, promoters of solar cookers must make potential users aware of the limitations of these devices, and emphasize that they are meant to complement, not replace, traditional fuel-burning stoves. At the same time, solar cookers should be introduced with fuel-efficient varieties of stoves that burn wood, charcoal, or other traditional fuels as part of an overall plan to reduce fuel consumption. Portable fired-clay stoves and other alternatives might be incorporated into such a plan. The important point is to emphasize the complementary nature of these technologies, and conduct training accordingly.

Second, promoters must pay more attention to providing good designs and better materials. Designs should be technically sound, incorporating research findings of recent decades. They also must be appropriate for the local geography, market conditions, cooking traditions, etc. A single change in design or materials can affect performance significantly. For example, one solar oven project in Lesotho ran into problems because exposure to the sun caused the black paint on the interior to give food a strange taste. The problem could have been avoided if another type of paint had been used.

This example illustrates the third consideration, which is to make sure there are enough quality materials to cover both original construction needs and spare parts. To do this, promoters may have to buy materials at bulk rates to achieve the necessary economies of scale. Long-lasting black enamel, for example, might have to be custom made and imported, and would have to be brought in quantity to reduce unit costs.

Fourth, a solar cooker that is both effective and durable is probably far too expensive for those people who need it most. So, promoters must develop better systems or designs to enable solar ovens to become more competitive economically, and to help users make the capital investment needed to obtain them. On the other hand, solar cookers that are given away often tend to be regarded as worthless. This seems to be a problem that sociologists, economists, political scientists, and other should be tackling, not just with respect to solar cookers but all new technologies. Solar cookers would make a valuable test case in dealing with this problem, since they are so closely involved with one of life's most basic necessities, yet they are usually far beyond the scope of what the individual user could make for himself, even with outside help. And finally, those promoting solar ovens, whether expatriates or local citizens, should use them to cook their own daily meals. It is important to create a popular image that solar cooking is modern and prestigious.

IV. FUTURE OF THE TECHNOLOGY

Currently, many of the most promising solar cooker designs exist only as prototypes, usually built in university laboratories for experimental purposes. As a result, they were not designed to be produced efficiently in large numbers. The next major technological step that must be taken is totally redesigning these cookers from the standpoint of manufacturability. Improvements in terms of simplicity, cooking efficiency, and ease of use should also be made.

SUPPLIERS AND MANUFACTURERS OF SOLAR COOKERS

SUPPLIERS

House of Russcar 3908 West Franklin Street Richmond, Virginia 23221 USA (Product: Swiss design solar concentrator)

Solar Usage Now, Inc. Box 306 420 East Tiffin Street Bascom, Ohio 44809 USA (Product: Direct-focusing and oven cookers)

MANUFACTURERS

Clevlab, Inc. Box 2647 Littleton, Colorado 80161 USA (Products: Solar and hybrid ovens)

Etampes et Mecanique L. Serafini 9 CH du Centurion CH-1227 Carouge-Geneve SWITZERLAND (Product: Swiss design solar concentrator)

Kerr Enterprises, inc. P.O. Box 27417 Tempa, Arizona 85281 USA (Product: Solar Box Ovens)

Sunshine Cooks, Ltd. 11806 North Tower Drive Fountain Hills, Arizona 85268 USA (Product: Adams-type solar cookers)

BIBLIOGRAPHY

Bowman, T.E. "Solar Cookers." Paper presented at the Simposio Sobre Tecnologia Aplicada a Sistemas de Inergia Solar, Queretaro, Mexico, January 29-February 3, 1979.

Bowman, T.E. "Solar Cookers: Test Results and New Designs." Appropriate Technology for Underdeveloped Countries. San Salvador, El Salvador: UCA/Editores, 1979, pp. 378-404.

Bowman, T.E., and Blatt, J.H. Solar Cookers: History, Design, Fabrication, Test, and Evaluation. Report CREA-78-1. Melbourne, Florida: Florida Institute of Technology, March 1978.

Bowman, T.E.; Sharber, J.R.; and Blatt, J.H. Solar Cookers for Haiti - A Feasibility Study. Contract AID/ta-c-1333. Washington, D.C.: U.S. Agency for International Development, December 1977.

Fang, P.H., and Swannack-Nunn, S. "Chinese Solar Cookers." Appropriate Technology 5 (February 1979): 4-5.

Halacy, D. "Two Simple Solar Cookers." Mechanics Illustrated, October 1978, pp. 44-45.

Khanna, M.L. "Solar Heating of Vegetable Oil." Solar Energy 6 (1962): 60-63.

Lafavore, M., and Sellers, D. "Cooking with the Sun." Organic Gardening, August 1980, pp. 88-99.

Landre, S. "A Computer Simulation of the F.I.T. Cooker Number 3." M.S. thesis, Florida Institute of Technology, 1980.

Lippert, J. "Solar Cookers Face Many Problems." VITA News, October 1982, pp. 8-12.

Lof, G.O.G., and Fester, D.A. "Design and Performance of Folding Umbrella-Type Solar Cooker." Proceedings of the United Nations Conference on New Sources of Energy, Vol. 5, Solar Energy: II. Rome, Italy: United Nations, 1961.

Patel, S.B. Status Report on Solar Cooker Research. Bombay, India: Land Research Institute, October 1981.

Renaison, G.P. "A Computer Simulation of the Telkes Oven." M.S. thesis, Florida Institute of Technology, 1980.

Sinto, S. "Further Development of the F.I.T. Cooker Number 3." M.S. thesis, Florida Institute of Technology, 1982.

Tabor, H. "A Solar Cooker for Developing Countries." Solar Energy 10 (1966): 153-157.

Telkes, M. "Solar Cooking Ovens." Solar Energy 3 (January 1959): 1-11.

Telkes, M., and Andrassy, S. "Practical Solar Cooking Ovens." Proceedings of the United Nations Conference on New Sources of Energy, Vol. 5, Solar Energy: II. Rome, Italy: United Nations, 1961.

United Nations. Food and Agriculture Organization. "Report on Tests Conducted Using the Telkes Solar Oven and Wisconsin Solar Stove Over the Period July to September 1959." Proceedings of the United Nations Conference on New Sources of Energy, Vol. 5, Solar Energy: II. Rome, Italy: United Nations, 1961.

Vaughan, B.D. "Appropriate Technology: A Simple Solar Cooker from India." The ADAB News, March 1980, pp. 8-9.

Von Oppen, M. "An Automatic Tracking Device for the Sun Basket." Appropriate Technology 5 (August 1978): 7-8.

Von Oppen, M. "The Sun Basket." Appropriate Technology 4 (November 1977): 7-10.

Whillier, A. "A Stove for Boiling Foods Using Solar Energy." Sun at Work 10 (1965): 9-12.

Yenamandra, N. "An Experimental Investigation of a Flat-Plate Solar Steam Cooker." M.S. thesis, Florida Institute of Technology, 1978.