OVERVIEW

Soil is a universal building material and is one of the oldest known to humanity. Simple soils (without additives), or soils improved by adding stabilizing materials such as bitumen or cement, are suitable for homes, schools, roads, and other construction.

For construction purposes, soil is usually formed into blocks. Two general types of blocks are described here: adobe block and stabilized earth block formed under great pressure. Adobe blocks are made from moistened soil that may be mixed with straw or other stabilizers. They are formed without pressure and usually cured in the sun. Stabilized earth blocks (sometimes called rammed earth blocks) are made from soil mixed with stabilizing material such as Portland cement, formed into blocks under high pressure, and cured in the shade.

Low cost is a primary advantage of soil block construction. An overall cost reduction of about 50 percent over conventional construction can be realized. Other advantages are that building materials are usually readily available and little skill and training are required for their use. The material is culturally acceptable in nearly all countries, including the United States.

SOIL CHARACTERISTICS

The composition of soil varies from one region to another, and with soil depth. In any one area, it may be desirable to mix soils from several locations or depths to obtain a composition more suitable for construction.

The primary components of soil that are of importance in construction are sand, clay, and silt. (Organic materials are also found in surface soil. These tend to reduce the quality of the blocks.) The fraction of clay in the soil is important because it acts to bind the larger soil particles together but the clay content should not exceed one-third. Above that, deep cracks and weakening of the dried blocks are likely to occur. Silt, which is usually found mixed with the sand, should not exceed one third because silt is vulnerable to erosion from wind and rain.

Proportions of sand, silt, and clay vary widely. One of the few soil block standards that exist is California's Uniform Building Code Specification, which recommends 55 to 75 percent sand, and 25 to 45 percent day and silt. A good mixture for most blocks might be:

sand .... 65 percent clay .... 20 percent silt .... 15 percent

To assure that the composition to be used is suitable for construction, several test blocks should be produced using various mixtures. After curing, the test blocks should be hard and resist a scratch or prick from a knife. Striking two compressed/stabilized blocks together should produce a click sound. The blocks should sustain a drop of two feet (.6 meter) without breaking. If the block crumbles or breaks, the sand or organic content is probably too high, and clay should be added to the mix. On the other hand, if large cracks appear during curing, the clay content is probably too high and sand should be added to the mix.

TESTING THE SOIL

Soil tests should be made before any block production is started. If the testing is not done first, a great deal of time and money may be wasted in the production of unusable blocks. The agricultural departments of most countries can provide laboratory tests at modest costs. If field tests must be made instead, some simple methods to determine the soil's suitability can be tried.

Composition Test

- Pass the soil through a 1/4" (6mm) screen to remove stones and other large particles.

- Pour the screened soil into a wide mouth jar until it is half full.

- Fill the jar with water. (You may add two tablespoons of salt to make the soil settle faster)

- Cover the jar tightly, and shake vigorously for two minutes.

- Let settle for at least 30 minutes.

The small gravel and sand will settle rapidly to the bottom of the jar. The clay and silt will settle more slowly. After 30 minutes, the jar should look like the drawing in Figure 1c. Hold a scale vertically on the side of the jar to measure

the amounts of sand, silt, and clay. Record the sample number and the amounts. Then convert the amounts to percentages.

Compaction Test

In addition to the soil composition test, a compaction test should be done to determine the packing quality of the clay, which depends on the percentage of clay in the sample and the quality of the clay itself. A simple field test can be done as follows:

- Take a handful of dry, screened earth and add some water to it until it is damp enough to form a ball when squeezed in the hand, but not so damp that it leaves more than a slight trace of water in the hand when squeezed.

- Drop the ball from a height of about 3 feet (1 m) onto hard ground. If the ball breaks into a few small pieces, the packing quality is good to fair. If it disintegrates the quality is poor and a soil mix with more clay should be prepared and tested.

Shrinkage Test

If stabilizing material such as Portland cement is to be added to the soil, a shrinkage test of the soil should also be made. This test will indicate the suitability of the soil and also the best cement-to-soil ratio to use. It measures the shrinkage of soil that contains no stabilizer. As shown in Figure 2, the box

should have these inside measurements: 24" x 1-1/2" (4 cm x 4 cm x 60 cm).

To test soil with this method:

- Oil or grease the inside surface of the box thoroughly.

- Pack the box well with moist soil (previously passed through a 6mm to 10mm (1/4" to 3/8") mesh screen. The soil should be moistened to pack well, but it should not be muddy.

- Tamp, especially at the comers.

- Smooth off the surface with a stick. + Place the box in the sun for three days or in the shade for seven days. It should be protected from rain.

Measure the contraction (shrinkage) by pushing the dried sample to one end of the box.

Shrinkage Cement to Soil Ratio

Not over 1/2" (15 mm) 1 part to 18 parts

Between 1/2" and 1" (15 mm - 30 mm) 1 part to 16 parts

Between 1" and 1-1/2" (30 mm - 45 mm) 1 part to 14 parts

Between 1-1/2" and 2" (45 mm - 60 mm) 1 part to 12 parts

When lime is used instead of cement use double the amount. Do not use the soil if it has many cracks (not just three or four); if it has arched up out of the box; or if it has shrunk more than 2" (60 mm).

MAKING ADOBE BLOCKS

To make adobe blocks, add water to the soil mix until it is plastic enough to mold. Water content should be between 16 and 20 percent of the soil by weight. The water and soil must be throughly mixed. Since all except the dryest soils will already contain some water, it is advisable to test the sample for water content first. Do this by weighing a soil sample, drying it, and then reweighing it to calculate water content.

Even the best adobe blocks may develop some cracks. To reduce the number of cracks, and also to make the blocks more weatherproof, stabilizing materials are often added to the mix. When stabilizers are used they must be thoroughly mixed with the soil or much of their benefits will be lost. The most widely used stabilizers are straw, rice husks, asphalt emulsion, Portland cement, and lime.

Asphalt emulsion can improve the waterproofing quality of the blocks, and also their elasticity and toughness, so that they are less likely to break during handling. Add asphalt emulsion between 5 and 15 percent by weight to the dry soil mix For soil mixes with high sand content (55 to 75 percent sand) the asphalt emulsion should be nearer the 5 percent figure.

Portland cement stabilizers improve the bonding properties and add strength to the blocks. Only 5 to 6 percent cement by weight is needed for soil mixes with high sand content, but up to 20 percent by weight may be required for soils high in clay and silt. If the soil requires a large percentage of cement, it can be combined with an equal amount of lime, which costs less.

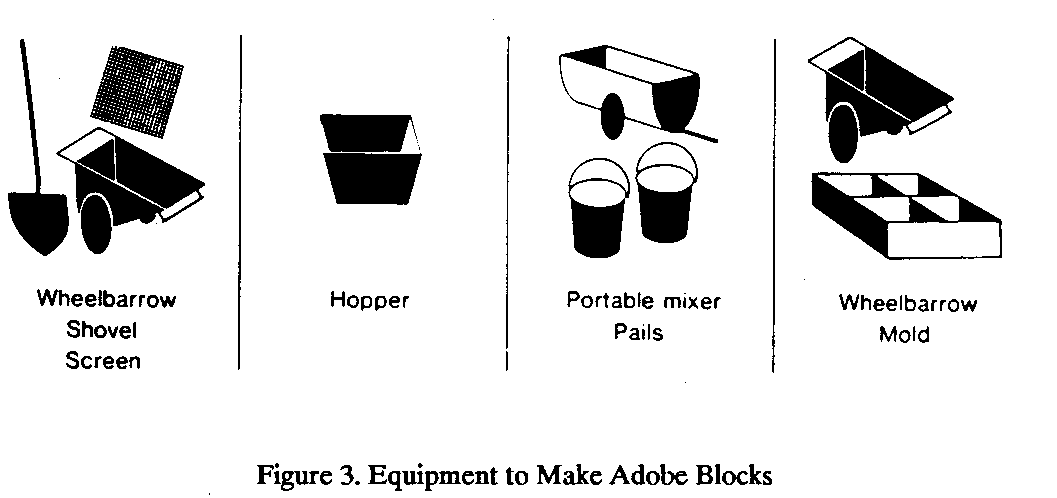

Equipment required for making adobe blocks is shown in Figure 3. The number of

shovels, molds, etc, will depend on the size of the job. Using this equipment, and supplied with the mixed adobe, a team of two molders can produce about 1,000 blocks (10 x 4 x 14") per day.

Select a large level area for mixing, molding, and curing the adobe. Mixing can be done in a hopper, or by making a shallow mixing pit in the ground. If possible, make the blocks near the construction site. If the mix is lumpy even after repeated working, let it soak overnight.

Block molds can be made in various sizes to fit the needs of the construction. But adobe blocks should not be larger than 81cm (32") around the outside. A gang form that will mold eight blocks of .009 cu. meter (one 1/3 cubic foot) can be operated by one worker. Before starting work, the mold should be thoroughly soaked with water to prevent the adobe mud from sticking to it.

Production steps are as follows:

- Rake or drag a large ground area level.

- Place mold on level area, on a piece of building paper if available, and dump the mud from a wheel barrow or hopper into the mold. Work the mud firmly into all corners of the mold.

- Scrape off excess mud from top of mold to leave a smooth, flat surface.

- Remove the mold by lifting it slowly and evenly up from the ground level. Move the mold to the next adjacent level area and repeat the process.

Blocks must be allowed to cure for about 14 days. After several days, the partially cured blocks may be carefully turned on edge so they dry more evenly. On very hot days, in direct sunlight the blocks may dry too rapidly and crack. To prevent this, cover the blocks with paper, leaves, or straw. Since rain will destroy unstabilized blocks, waterproof tarps may be needed.

To store the blocks after they are cured, stack them on edge. If left stacked flat, they will break of their own weight.

MAKING COMPRESSED EARTH BLOCKS AND TILES

Compressed earth blocks can be made by ramming the earth in forms, or by using a block making machine, such as the CINVA-Ram Block Press. Blocks made by machine are less costly and have superior uniformity.

Some machine made blocks tested by the U.S. National Bureau of Standards had compressive strengths up to 800 pounds per square inch (56 Kg/cm), with 300 to 500 psi strength as the average. (This is three to eight times the compressive strength of adobe blocks). These test blocks contained 50 percent sand, and 50 percent clay and silt, mixed with 8 percent cement by weight.

Although one worker can make blocks with the CINVA-Ram, the process is best as a team effort with two to four workers each performing one task. (It is good to rotate tasks among the workers on an hourly or daily basis.) The CINVA-Ram is portable and can easily be moved about the work site to reduce carrying raw materials or finished blocks.

Floor tiles can also be made with the machine, using inserts to adjust for the thinner tiles. The mixture for floor tiles is two parts fine sand to one part cement. Mineral coloring can be added to produce colored tiles.

Average production rates and cement required are:

- Average number cement blocks or tiles (made by two workers per day) 300-500

- Average no. blocks for a two room house 2500

- Typical block size: 9x14x29cm (3-1/2"x5-1/2"x11-1/2") which lay up to: 10x15x30cm (4x6x12 inches).

- Average number blocks per 100 lbs cement: 150

Stacking the blocks for curing requires care. The blocks should be stacked on edge on clean planks. If planks are not available, stack on flat ground that has been covered with paper or leaves. The blocks should be covered with plastic or old cement bags that have been cut open. Stacks should not be greater than five blocks high, and some air space should be left between the blocks. For the first four days, sprinkle the blocks lightly with water to prevent them from drying too quickly. The total curing time is about 14 days, depending on the weather.

BUILDING WITH STABILIZED EARTH BLOCKS

A firm, flat, water-resistant foundation should be built first using blocks with a higher percentage of cement and lime. Blocks should be joined by mortar about one half inch (1.25 cm) thick. The recommended mortar mix (by weight) is:

- one part cement + two parts lime + nine parts soil (used to make the blocks)

Let the applied mortar dry for about a week; then paint the mortar joints with a thin, milk-like mix of cement and water. Stir this mixture often. After a day, the finished walls can be coated (3 coats recommended) with this same mixture, or with a coat of lime. Or, a waterproofing coat of silicone based wash may be added.

Sources:

Alfred Bush, Chris Ahrens, Balla Sidibe, VITA volunteers

References:

Making Building Blocks with the CINVA-Ram Block Press. Arlington, Virginia: VITA, 1977.

Bush, Alfred. Understanding Stabilized Earth Construction. Arlington, Virginia: Volunteers in Technical Assistance, 1984

"Building Materials and Structures Report BMS 78", Gaithersburg, Maryland: US National Bureau of Standards

Sidibe Balla. Understanding Adobe. Arlington, Virginia: Volunteers in Technical Assistance, 1985

U.S. Agency for International Development, "Handbook for Building Homes of Earth", Action Pamphlet No. 4200.36, Wolfkill, Dunlop, Callaway, Washington, DC, Peace Corps, 1979.

Ferm, Richard. Stabilized Earth Construction: An Instructional Manual. Washington, D.C.: The International Foundation for Earth Construction.

Manufacturer:

The CINVA-Ram Block Press is manufactured in Bogota, Colombia, by METALIBEC, S.A. The press may also be purchased in the USA for $400 (1987) from Schvader Bellows Inc., 200 West Exchange Street, Akvon, Ohio 44309-0631. Telephone: (216) 375-5202. Similar, locally manufactured presses can often be found in other developing countries.