VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Small-Scale Brick Making ISBN: 0-86619-312-X [C] 1990, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people chooe technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Sandra Wark handling typesetting and layout, Patrice Matthews handling Volunteer coordination, and Margaret Crouch as project manager.

The author of this paper, VITA Volunteer David W. Thomas is a consultant in practical ceramics.

The paper was reviewed by VITA Volunteer V.F. Nast, retired from the lime and cement business, and Victor Palmeri, a consultant in the ceramics industry.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field proejcts; and published a variety of technical manuals and papers.

THE INVENTION OF FIRED BRICK

Sun-dried earthen blocks (adobe) have been used as a building material for thousands of years, especially in very dry areas. Clay is mixed with water, and sometimes straw to keep the finished blocks from cracking, and formed by hand into blocks. The blocks are placed in the sun until they are thoroughly dry. The dried blocks are hard, but they soften and come apart in heavy rains.

The invention of more durable "fired" or baked brick was an event of enormous importance. Nearly 7,000 years ago people discovered that exposing clay to high heat would convert it to a hard, glassy material (called ceramic, from the Greek word for earthenware pottery). The first ceramic materials were cooking vessels and figurines; eventually, about 3,500 years ago, the technology was applied to building blocks.

Like sun-dried blocks, fired bricks were modular and easily handled. But fired bricks were very hard, as well as resistant to attack by weather and fire. They were usually cheaper than stone and often could be manufactured close to building sites. Firedbrick technology made it much easier for people to make durable buildings, walls, roads, and bridges. The Romans combined brick with concrete and developed new kinds of buildings. New kinds of cities, political institutions, and arts flourished. Today, extended and refined ceramic technology produces not only building materials, but special porcelains, glasses, and even such electronic devices as radio transistors and computer chips. Although bricks are flat and rectangular, their relatively small size and irregular surfaces require the use of mortar for assembly into walls and other structures. Mortar is an adhesive made of cement, lime, and sand, to which water is added at the time of use to make a paste. It hardens in a few hours.

Today, 65 percent of the bricks made in the world are used for dwellings; 35 percent are used for walls, public buildings, and other non-dwelling structures. In addition to common or ordinary building bricks, there are glazed and other decorative bricks and special "firebrick," designed to protect surfaces from intense heat. Bricks can be manufactured by large automated factories; they can also be made on a small scale by one or two families working together in a rural setting. This paper describes the small-scale manufacture of ordinary bricks.

Building bricks are made with clay and water, and fired with locally available fuels. Strenuous physical work is involved. The rewards, on the other hand, are enormous. Durable housing that resists the elements generates a feeling of purposefulness and security to those so sheltered. The comfort and improved health that comes with living in a dry house, one that holds warmth in cool weather or remains cool in the hot sun, reward the hard work involved.

THE TECHNOLOGY OF FIRED BRICK

Clay is often abundant in old river and lake beds because it is the finely granular end product of the breakdown by water of rocks and minerals. The minerals from which clay is derived contain oxides of such common chemical elements as aluminum, iron, manganese, and silicon, as well as other compounds of aluminum and silicon. When exposed to high heat (900 [degrees] C or more), some of the materials melt to form a glue that holds the unmelted particles together. The process is called vitrification; the melt becomes glassy when it cools. Brick must be strong; strength comes from vitrification, the kinds of chemicals in the clay, and the temperature and duration of firing. The color of fired brick is usually rust-red because of the abundance of iron oxide, [Fe.sub.2 O.sub.3].

In primitive manufacture, clay may be dug and bricks formed by hand to produce 20-30 bricks per day. Developing the desired. hardness through crude firing may result in bricks of low quality and is usually accompanied by inefficient gathering of fuel. But rural brick making can be more efficient. Its five processes, described below, are as follows: 1) winning or mining the clay; 2) mixing the clay with water to "plasticize" it or make it moldable by hand; 3) forming or shaping the bricks; 4) drying them; and 5) firing them in a special furnace, the kiln, to develop lasting hardness.

PREPARING MOLDED BRICKS FOR THE KILN

Clay Winning

Clay winning and clay preparation are often combined. Usually, a worker chips away small amounts of a clay bank with a hoe or adze. If the clay formation is shaped like a flat lens at the ground surface, the worker digs a hole about one meter deep and three meters in diameter. Then, with short chopping strokes, the worker "shaves" the clay from the wall of the hole. The flakes of clay so removed are less than a centimeter thick. They may curl as they are removed from the clay bank face. Where the clay appears as an outcropping on the side of the hill, the operator moves the flakes to a small pit or hole nearby. The hole receives the shavings and provides a location where the clay, newly cut from the bank, can be mixed with water. The shavings are quite light compared to the clay remaining in the bank face.

Clay Preparation

Now, small amounts of water are worked into the clay, usually by treading with the feet. People characteristically dance and hop when they mix water and clay in this manner. Often, one person chips the clay face while another mixes the clay with water. When the mixture reaches the paste-like consistency that is necessary (as judged from experience), it is placed in a bucket or, if available, a wheelbarrow, and removed to the brick-forming area.

Forming the Bricks

There is no "standard" brick size, but setting the length of the fired brick to a little more than twice its width allows a variety of bonding patterns during bricklaying. The dimensions of fired bricks usually depend on local tradition, but are often 20 to 22 cm long, 9 to 11 cm wide, and 5 to 7.5 cm thick. However, the unfired bricks are made larger than the finished size, to allow for shrinkage during firing. The amount of shrinkage depends upon the clay and the firing conditions and is learned by experience.

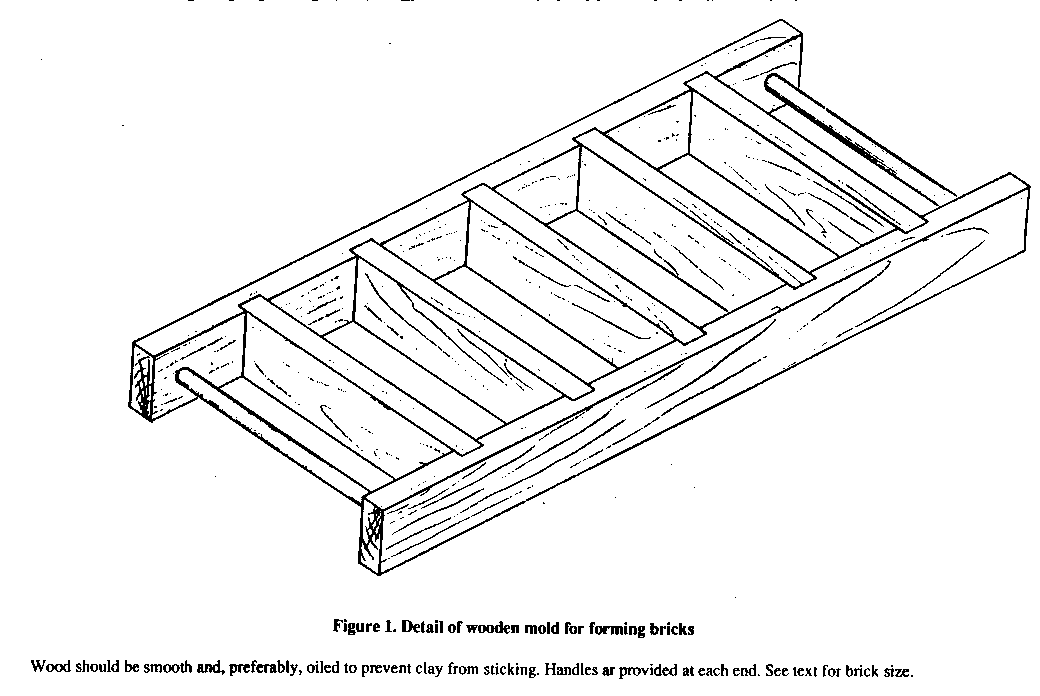

Bricks are formed simply by pouring or dumping the clay-water mixture into a mold that has up to four cavities, so that several bricks are formed at one time. The mold is usually made of wood and is open on both faces (Fig. 1). It has handles at each end

for handling and lifting.

The molds are coated with oil or sand to make it easier to remove the formed bricks from the wooden sides. If sand is used, grains about 0.5 mm in size are sprinkled on the mold surfaces after the mold has been immersed in water. Oil is scarce in most places, but where it can be used it will be absorbed by the brick and burned during firing, thus providing part of the fuel requirements.

The molds are filled on level ground. Usually, two operators are needed in the casting or pouring of the bricks. After the bucket of clay-water mix has been poured into the open mold cavity, the mold is vibrated slightly by striking it with the heel of the hand. This causes the material to settle and level off at the top. Some water is absorbed by the ground; some comes to the top and runs off. Excess material lying on top of the mold is then pushed off with the hand or a board and saved for the next filling.

The consistency of the mixture is critical. Mixtures that are too watery tend to flow or cause the bricks to slump when the mold is lifted free of the mixture. Mixtures that are too stiff may not fill the corners of the mold. The bricks will then be irregular and jagged. Once the proper consistency, or water-clay ratio, is determined by experiment, the pit operator ensures that it is maintained throughout the working day.

After excess clay is removed, the mold is lifted up and freed of the cast brick. Two persons are needed to lift the mold vertically. Once free of the bricks, the mold is again wetted with water and sand is sprinkled on the inner surfaces. It is then placed on the ground in front of the bricks just released from the mold. Thus, the brick making process becomes continuous, the mold moving progressively to make row after row of bricks.

Drying the Bricks

<FIGURE 2>

The drying ground should be level and free of surface irregularities. An open and shade-free area is preferred to speed drying. If daily rainfall is expected, the formed bricks are protected with a cover that has no sides, so that the air can move freely around them. After about three days in the flat or "as made" position, the bricks can be handled without deforming or crumbling them. At this stage, they must be stacked in a special manner to speed up the final stages of drying.

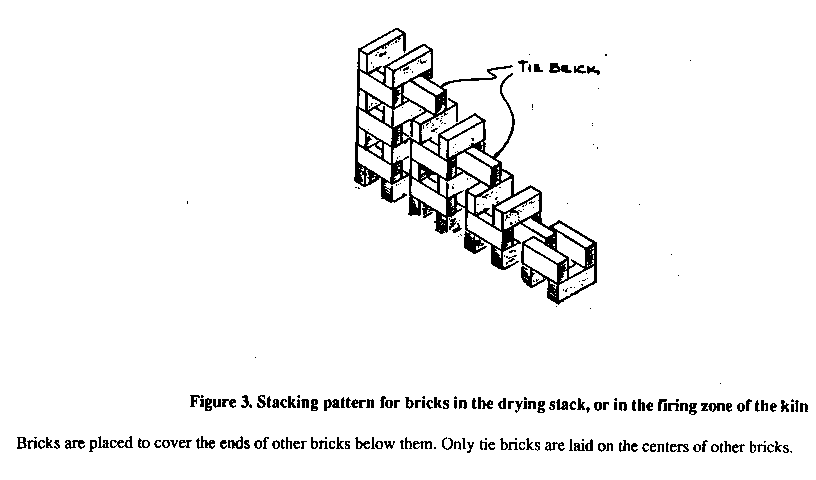

Figure 3 shows an effective stacking pattern for drying bricks.

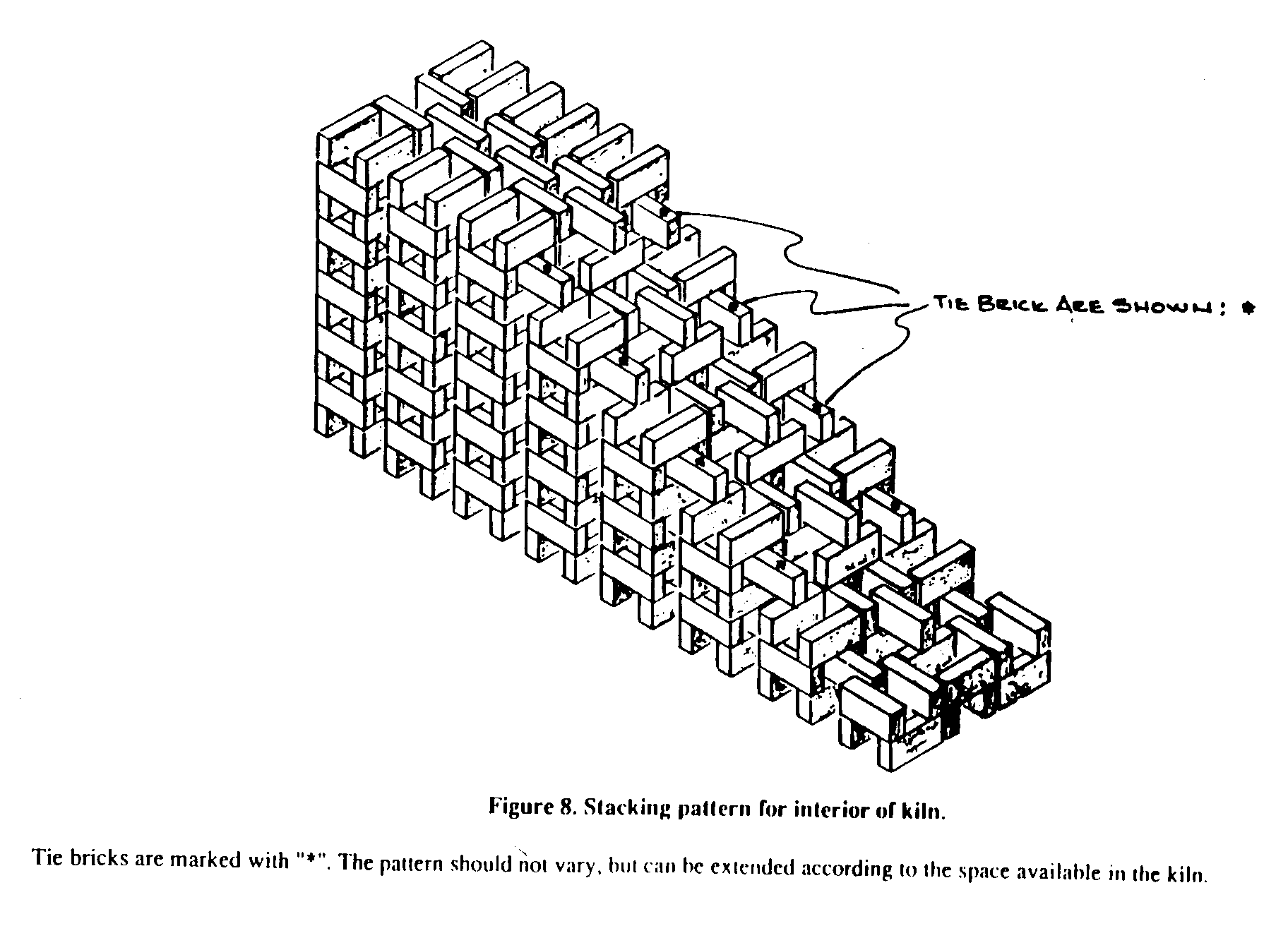

Two bricks are first placed on the ground resting on the face that is approximately 20 cm by 6 cm and one brick-length apart Then two bricks are placed upon the first two, at right angles to them, so that the second two bricks cover the ends of the first pair. To achieve stability as the pile grows taller, a "tie brick" is used, extending from the center of one brick to the center of another that is at the same level in an adjacent pile. Thus, the tie bricks link each vertical column of bricks to its neighbor. Vertical growth and alternate tie-brick placement continues until the drying stack is about 1.5 m high and of any convenient length, generally about 3 m.

The bricks are dried by prevailing winds that circulate through, the open spaces of the stack. The additional factors that favor rapid drying are: 1) high air temperature; 2) low humidity; and 3) using clay containing a small proportion of very fine particles, which hold more water.

A clay that has a large proportion of extremely fine particles will absorb and hold more water, the evaporation of which can cause bricks to crack. This fault can be corrected by adding some sandy material to the clay mix. The sand should be fine, with most of the grains smaller than 0.5 mm and a few as large as match heads.

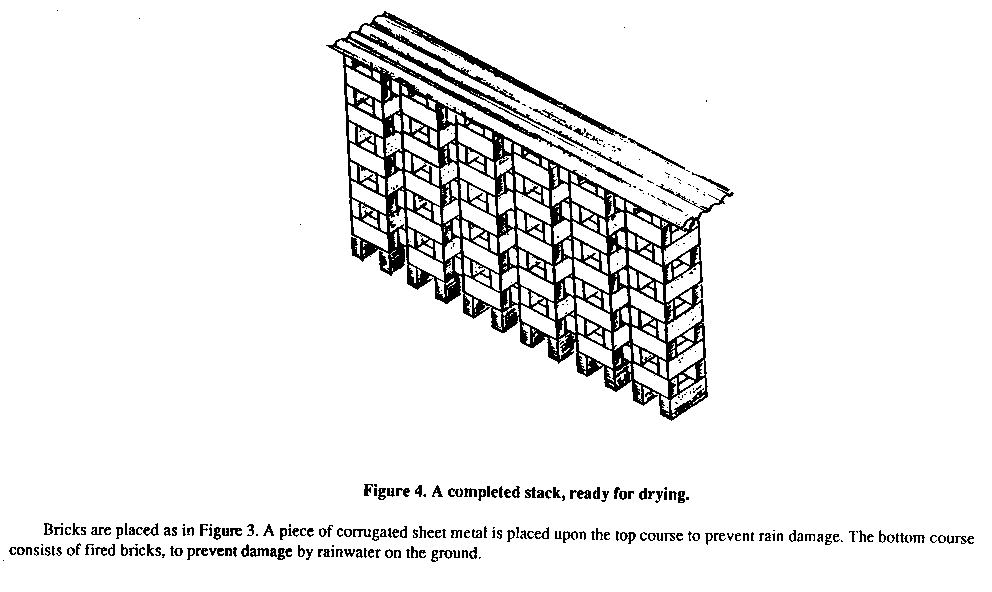

At least a week is needed for complete drying. The stack must be protected from rain during this time, because the bricks will lose strength or even crumble if they get wet. Both the top of the brick stack and the base must be protected. Top protection that will shed ordinary rainfall is provided by placing a few pieces of lightweight corrugated metal upon the bricks (Fig. 4).

Bottom protection is provided by building the stack upon a first course of previously fired bricks. Fired brick is resistant to water and will remain hard when wetted by runoff.

Drying is a critical process that requires the exercise of patience. Bricks with even a trace of water should never be placed in the kiln. If the water content is too high, a brick may explode in the kiln when heated. Completeness of drying can be tested easily because clay usually assumes a lighter color as it dries. Upon being broken in half, a thoroughly dried brick shows no color difference between the outer part and the center. Another method is to weigh a brick taken from the stack. Then place it near an oven or other heat source for a few hours. If it loses weight, the bricks in the stack f rom which it was taken are assumed to be incompletely dried.

BUILDING THE KILN

Where bricks are made on a very large scale, firing is a continuous process for which a tunnel kiln is used. Such a kiln is the largest single investment for the manufacturer and can cost a half million dollars or more.

In making bricks on a small scale, firing is a batch process. Kilns can be built of locally available material and can be fired with local fuels. The bricks are placed in the kiln, the fire started and needed temperature is reached. After several days of firing, the fuel supply is stopped and the kiln and its load are allowed to cool down naturally.

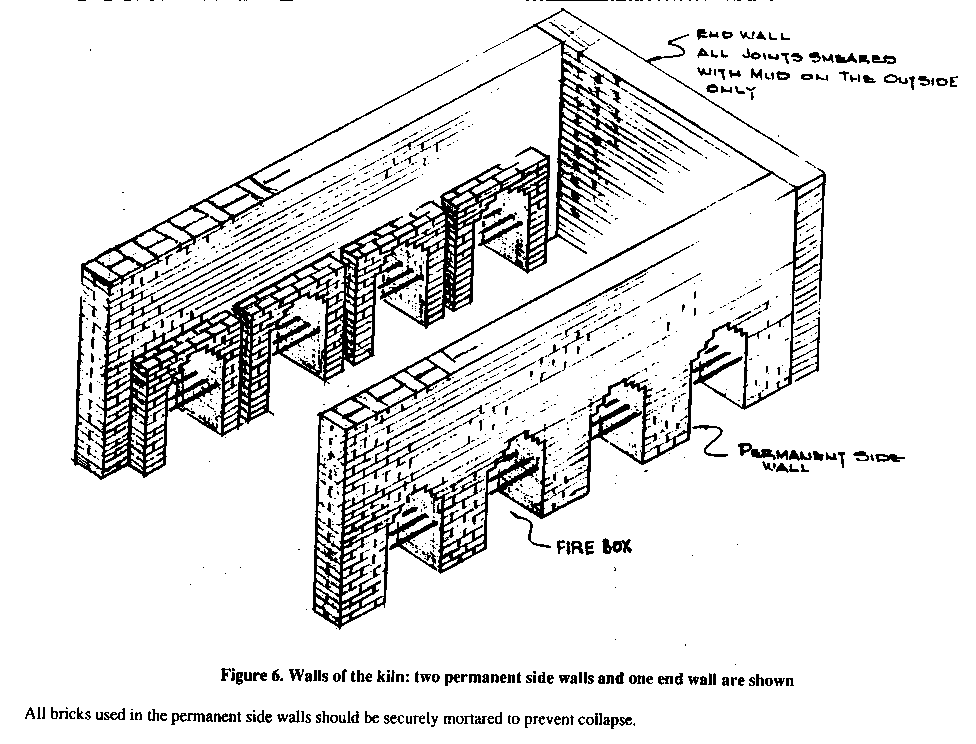

The kiln consists of the fire box, the flue system, the permanent side walls, and the mudded end walls. Haste in building the kiln can result in shoddy side walls and fire boxes, which, in turn, results in constant and time-consuming repairs.

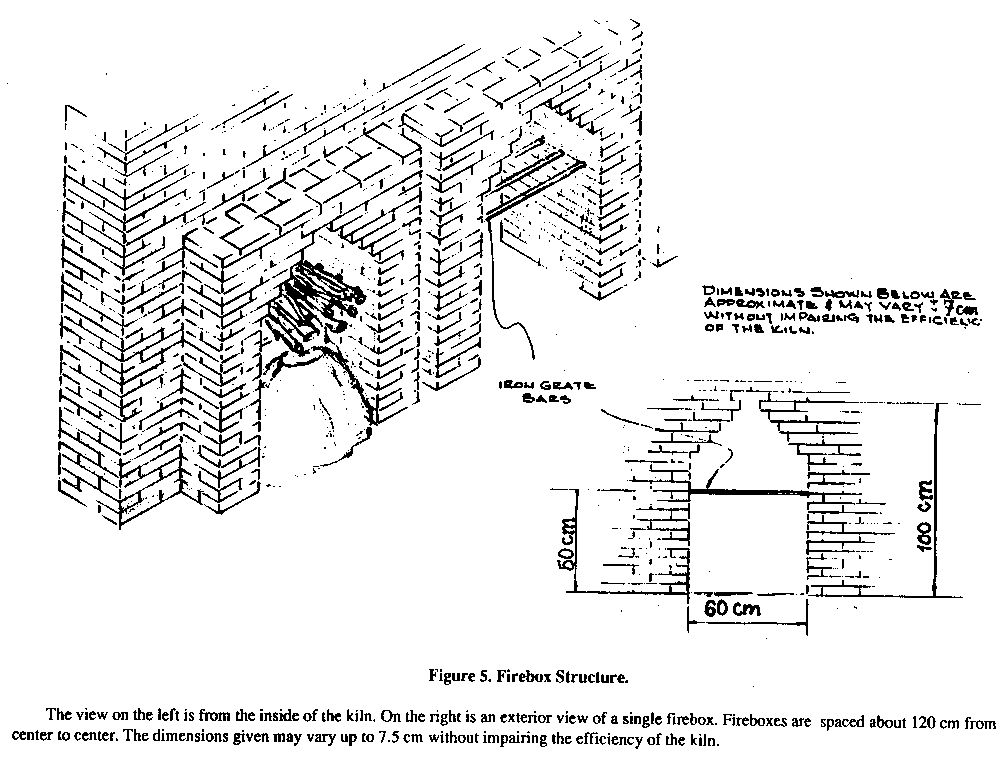

The Fire Box

The fire box is an opening in the permanent side wall into which the operator places the fuel. It usually measures 60 cm wide, 100 cm high, and 75 cm deep. The top can, but need not be, arched. In the center of the 60-cm span, about 50 cm from the ground, iron rods or grid bars are placed horizontally. The bars are 2 cm in diameter and are placed 7.5 cm apart to support the fuel. They are secured by embedding them in the bricks on both sides of the opening (Fig. 5).

The Flue System

The flue system includes the openings that let air and hot gases enter and leave the kiln, as well as spaces among the bricks stacked in the kiln for firing. It allows free movement of hot gases from the heat source in the fire box, to the bricks being fired, and finally to the upper parts of the kiln and out through provided openings, just as smoke and heat travel up a chimney. To bring this about, the bricks must be stacked as described below, under "Loading the kiln."

The Permanent Side Walls

The two identical, permanent side walls are built of previously fired brick; the fire boxes are apertures located in them. The walls are usually placed about 3 m apart and perfectly parallel. The bricks to be fired are placed in the area between the walls. The walls are normally two brick lengths or 50 cm thick (Fig. 6).

It is not necessary to have a supply of fired bricks on hand to build a first kiln. The side walls and fire boxes can be made of unfired brick; such a kiln is much smaller than the one to be built eventually. After the first firing, perhaps as many as 50 percent of the bricks in the kiln will develop enough hardness to be used. These are set aside; continued firings will yield an accumulation of bricks to make two full-sized side walls.

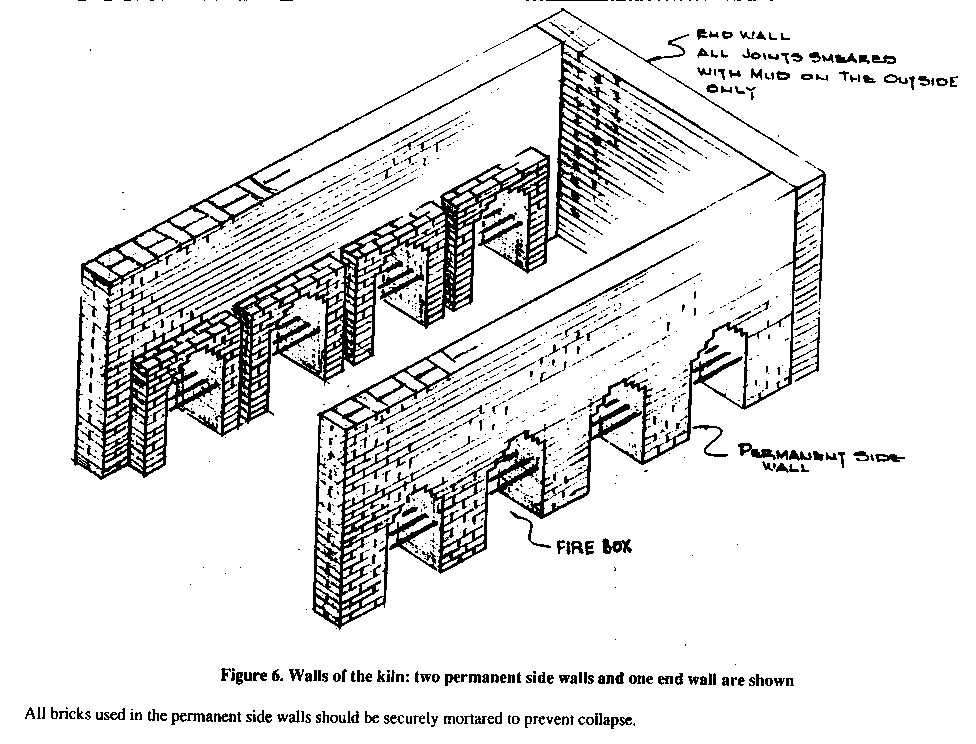

The Mudded End Walls

The mudded end walls are two temporary closures at the ends of the permanent side walls, constructed after the kiln is loaded. They are taken down to remove the load of bricks after firing. The mudded end walls may be made of previously fired or unfired bricks placed directly on each other (Figs. 6 and 7). The spaces

between the bricks are filled from the outside with a mixture of brick clay and water; it is smeared on by hand in the same way as spreading plaster on a house wall. The purpose of the mud is to prevent the escape of heat from the kiln between the bricks. Bricks used for these walls are seldom exposed to the heat that would harden them. For this reason, they are set aside to be placed in the inner kiln areas during later firings.

LOADING THE KILN

Once the kiln side walls and fire boxes are assembled, the kiln may be loaded with dried bricks. Careless haste in placing the bricks in the kiln can result in collapse of the entire mass, usually resulting in a complete loss of the batch of bricks.

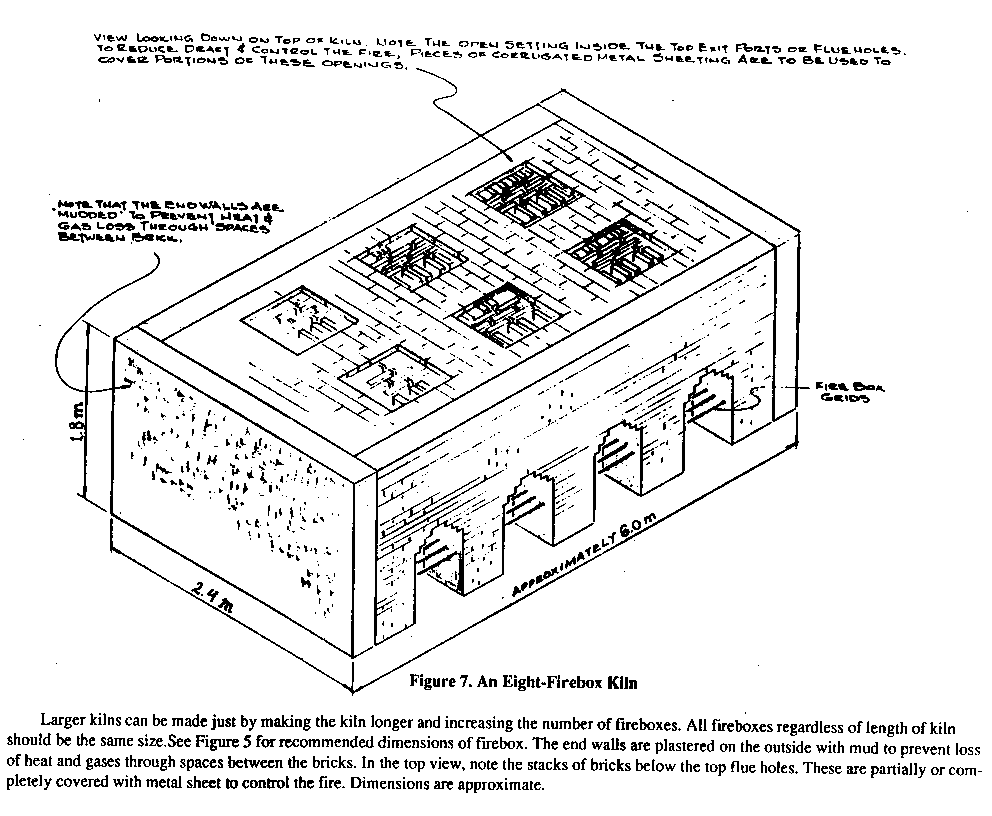

The dried bricks are first arranged between the permanent walls in the areas close to the fire box. Bricks in the fire box area are placed one pair on top of another, with pairs at right angles to each other, as in the drying stack. The same tie-brick system is used to give stability to the columns of bricks.

Once these areas are filled, the inner sections of the kiln are loaded. Here, the stacks of bricks are placed farther apart to allow free movement of hot gases. The keying technique is extended in two directions. In order to prevent internal topple or insecure and unstable piling of bricks, the rows are keyed, one to the other, by placing the second row of bricks close to (about 1 cm away from) the bricks in the first column. The bricks are arranged so that the sides of the bricks in the second row of columns are placed against the ends of the bricks in the first row. This setting is reversed for the next row, and so on until the entire kiln is loaded (Fig. 7).

Bricks in the ends of the kiln, close to the mudded end walls, are placed closer to each other to reduce the escape of heat through these walls. When the top course of bricks is built to form the kiln roof, its bricks form a solid platform interrupted by open areas 60 cm square (Fig. 8). As in the case of the end

walls, the close-set top bricks are mudded over to prevent the escape of gases and heat through cracks between them.

The flue system or draftway now extends from the fire box, through the stacks of bricks to the top of the kiln. It is at this point that the set of firing controls required on the kiln is installed. Pieces of sheet metal are provided that slide over the various openings to control the amount of hot gases that escape from the flue space. Thus, a piece of metal about 90 cm square is needed for each 60 cm by 60 cm opening in the top of the kiln. To create a greater draft and make the fires hotter, remove the covers. To dampen the fires and to hold the heat as long as possible, slide them over the openings, thus retarding the passage of gases and heat from the kiln.

FIRING THE KILN AND ITS CONTENTS

The Heating Period

Using wood as fuel will create the high heat necessary for complete firing of the kiln. It should be cut into 1.75-meter lengths. Other successful fuels include coffee husks, coconut hulls, dung, olive pits, and even burnable fabric scraps. A good supply of fuel in ready condition should be on hand when firing is started. A fuel shortage in the middle of a firing can result in loss of the entire load of bricks.

The fuel is placed on top of the grate bars and (for wood) extends only to the inner edge of the permanent side walls; it is pushed inward as the ends are consumed. A small fire is now started under the grate so that the flames traveling upward will ignite the fuel above. The metal covers on top of the kiln are opened to permit free access of air and create a draft from the fire box upward.

When the fuel is burning, the space under the grate bars allows entry of air for continued combustion. The space can be blocked with excess fuel or ashes, thus providing an additional control of draft. At early firing stages the area under the grate is free of fuel or ash.

After the fires have burned and smoked f or 10 to 12 hours, the operator may be able to see a slight reddish glow by viewing the inner part of the kiln through the archway of the fire box. When the entire inner mass of the kiln has developed a cherry-red glow, this part of the kiln is at the correct firing temperature (875 [degrees] C to 900 [degrees] C). To complete the firing and permit the interior of each brick to reach the correct temperature, the flue draft is retarded by sliding the top covers over about half of the flue openings. At the same time, the areas under the grates are blocked with fuel or ash. These adjustments retard heat loss from the kiln as well as allow all parts of the kiln to reach the needed temperature.

Holding and Cooling

Firing has now entered the holding or "soaking" period. Once achieved, these conditions must be maintained for at least six hours, adding fuel as necessary. Because of the reduced draft, less fuel will be needed than for the first firing stages.

At the end of the holding period, the fuel supply is stopped and the top plates are placed to cover the flue openings completely. Sometimes, operators also completely fill the openings of the fireboxes with ashes from previous fires to further reduce heat loss, thus holding the heat in the kiln as long as possible.

After about two days, the bricks can be removed from the kiln. First, the end walls are torn down starting with the upper sections. The bricks of the end wall that did not receive full heat can finished in subsequent firings. The mud used to close up the gaps between the bricks can be knocked off and does not damage them.

Bricks shrink during firing, sometimes as much as 10 percent. Thus, the stacks of bricks in the center of the kiln may be shorter after firing than before. After all the newly fired bricks are removed from the area between the two permanent side walls, the entire kiln, including the fire boxes, is swept clean of ashes, bits of clay, and broken bricks. It is now ready for another firing.

COMMERCIAL ASPECTS

Scale of Production

The scale of production described here will meet the housing needs of a few villages. A large, automated facility is needed for construction of a new city.

Marketing and Product Diversification

Marketing the bricks should not present problems. Wood as building material is already very scarce in many areas, as forests become transformed into crop and grazing land. The disappearance of forests brings about major climatic and other environmental disturbances, and has properly caused concern among farmers and officials. But clay is abundant in many places, and the kind of clay found at the surface of the earth is usually satisfactory for making building bricks.

Gaining experience in making common bricks may lead to the making of other clay-based products. These include tiles for roofs, walkways, and roadways, and glazed or decorative bricks for interiors and public buildings. The processes described in this paper for building bricks are fundamentally the same for other clay products. The clay for other kinds of brick may need to be mined from deeper locations.

BIBLIOGRAPHY

- Hand Operated Clay Crusher for Brickmaking. Appropriate Technology, Vol. 9, No. 3, Intermediate Technology Publications, 1982; 24-26.

- Wade, R.J. and Mason S.A., Stabilized Brick Manufacture and Construction. Technical Workshop, Papua New Guinea-University. Papua New Guinea University of Technology, Department of Chemical Technology, 1974.

- Brandt, W.O,, Manufacture of Burned Brick by Simple Methods. Volunteers in Technical Assistance, 1966.

- Kundu, T.K., A Feasibility Study of a Gas Fired Brick Kiln for Bangladesh. Thesis No. 1219. Asian Institute of Technology, 1977.